Master Pneumatic’s Multi Point Lubricators (MPL’s) were invented in the mid 1960’s and have been in service all over the world. First, let’s cover some basic terminology.

The heart of the system are small positive displacement pumps called INJECTORS, or Servo-Meters. You have three choices of maximum output but various methods of adjusting this output are offered. Full stroke volumes available are 1/2 drop (.015ml), 1 drop (.030ml), and 2 drop (.060ml). Master Pneumatic’s standard Servo-Meters can be adjusted down to 10% of maximum volume by an external adjustment knob. We also offer Servo-Meters that can be shut off entirely.

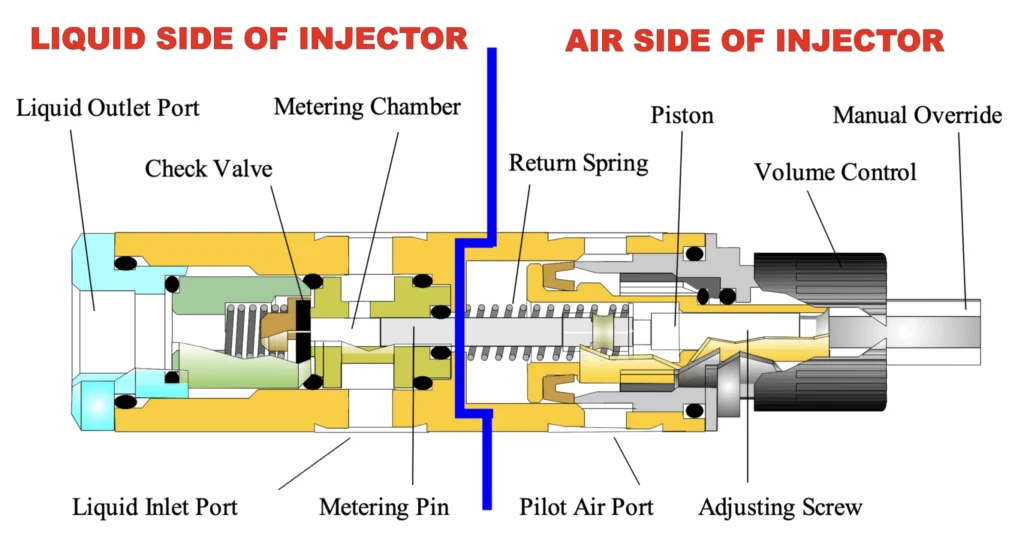

The MPL assembly can have 1 Servo-Meter or as many as 10 Servo-Meters. These assemblies can have an assortment of Servo-Meters with maximum output of 1/2, 1, or 2 drops. When an air signal is sent, the piston assembly extends the metering pin and displaces the volume of lubricant which you have dialed in by the volume control knob. That volume of lubricant is dispensed from the metering chamber, past the check valve to the outlet port. When the air signal is removed, the return spring resets the piston for the next lubrication event. In a valve/ cylinder circuit, the air pilot signal is usually tapped from the directional valve controlling cylin- der action (shown on the page 7). Lubrication can be delivered in either the rod or cap end of the cylinder, or both. Typically, the rod end is the port used to prevent excess wear to the rod gland.

In addition to adjusting oil volume with the Servo-Meter, we offer other methods of delivering the correct amount of oil, consistantly.

Integrated Controllers

Flexibility

Users can choose how often the adjusted volume of oil is delivered. There are a number of ways to accomplish this.

- Pulse Counter

- Frequency Generator

- External Solenoid Valve

- Interposed Solenoid Valve

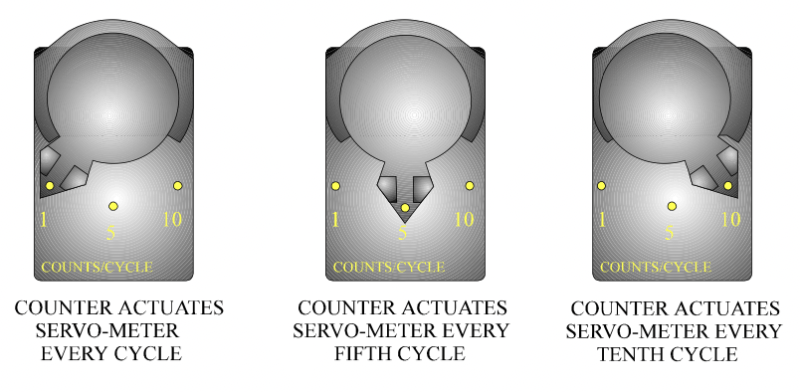

Pulse Counter

This option allows the user to select when the volume of lubrication is delivered. Each pulse counter can be field adjusted to allow the Servo-Meter(s) to dispense every 1, 5, or 10 cycles of the pneumatic device. If two pulse counters are installed, this frequency can be ex- tended to every 25, 50, or 100 cycles.

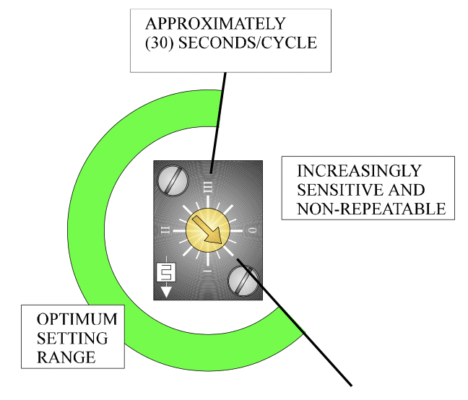

Frequency Generator

This is a pneumatic counter. It is generally used in applications where the user wants the Servo-Meter to dispense lubrication multi- ple times in the cycle. Since the Servo-Meters only operate when given an air signal, lubrication is only dispensed once in a cycle. By including the Frequency Generator, the user can adjust the MPL to deliver lubrication within a range of every 1-30 seconds per cycle. If the Pulse Counter and Frequency Generator were both used, the range could be extended from 1 second to 5 minutes.

External Solenoid Valve

Typically, external or remote valves are used for controlling Servo-Meters in MPL’s where the injectors are operated at differing times, independently.

Interposed Solenoid Valve

Here we install a solenoid operated valve between the base of the MPL and the Servo-Meters. The valve is actuated by an electronic signal when lubrication is to be dispensed. A PLC can be used to adjust frequency of lubrication with infinite adjustability. Some users have tied this option into a proximity switch to automate their process.

MPL’s can be controlled in many ways. Signal air can be supplied by external and interposed valves as shown be- low. The valves can be actuated manually, by proximity switches, timers, and/or the customers PLC. The signal air can be piped into the top or bottom, depending on the type of controls that are being used.

The oil supply can be dedicated to one or more MPL’s. It is important to ensure there is no entrapped air in the Servo-Meters and this can be accomplished by delivering the supply in the bottom and installing a site dome in the top.

Reference: Master Pneumatic

For more information:

Tel.: 02-384-6060 | Line: @flutech.co.th | Email: [email protected] | Facebook: @flutech.co.th | Website: https://flutech.co.th