What is the Glass Industry?

The glass industry includes the coloring of glass, polishing of spectacle and optical instrument lenses, manufacturing of ultraviolet cut glass, preparing the surface of mirror glass, and other glass specialties. Glass production involves two main methods – the float glass process that produces sheet glass, and glassblowing that produces bottles and other containers.

Broadly, modern glass container factories are three-part operations: the batch house, the hot end, and the cold end. The batch house handles the raw materials; the hot end handles the manufacture proper—the forehearth, forming machines, and annealing ovens; and the cold end handles the product-inspection and packaging equipment.

Glass Industry Solutions – Poppet Valves

ROSS® poppet valves are the product of choice for the all the major container plants globally. With its proven reliability and performance plus consistent switching times it has proven itself over many decades in this challenging and unforgiving environment. Its internal construction has been carefully calculated to produce strong shifting and sealing forces in each direction which results in a design which ensures high speed, repeatability and high shifting forces over the life of the valve.

ROSS® poppet valves have positive sealing with no sliding action to prevent damage and wear. They are also self-cleaning and dirt tolerant thanks to the smallest flow-through area across the poppet’s seal and seat which produces a high-enough velocity to blow out all dirt and foreign matter. Plus, the valve is self-compensating for wear by automatically changing stroke length due to height changes in the valve seal from burnishing. These valves are designed for repeatability, high-temperature service, high speed, and high-shift consistency over the life of the valve.

Featured Product

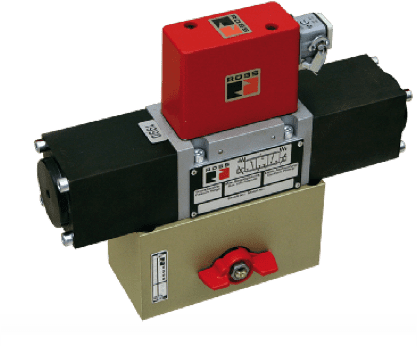

Proportional Valve

Applying proportional valve technology, which combines conventional valve know-how with electronics and sensors, makes it possible to introduce intermediate operating positions, in steps, within a range of 0 to 100%, with full adjustability and repeatable performance. The ROSS® Proportional Valve is a poppet design with direct acting solenoids that were specifically developed for glass industry applications. The ROSS® Proportional Valve is designed to pinpoint the required outlet pressure even though the required pressure may be considerably lower than the inlet pressure, thus ensuring that the operating pressure requirements of the machine are met precisely. The output pressure can also be changed to any pressure in the output range nearly as fast as the input signal can be changed. Therefore, use of Proportional Valves should be recommended wherever precisely controlled and regulated air pressure is crucial.

Other proportional valves in the market either utilize a constant or contained pilot air design, which continually adjust the pilot orifice to maintain the correct output pressure for the main valve, which makes them limited in both speed and accuracy of operation. ROSS® valves are available as plug and play solutions with various interfaces and customer specific electrical supply options or we can fine-tune the operation to your individual requirements.

สำหรับข้อมูลเพิ่มเติม โปรดติดต่อเรา:

โทร: 02-384-6060 | ไลน์: @flutech.co.th | อีเมล: [email protected] | เฟสบุ๊ค: @flutech.co.th | เว็บไซต์: https://flutech.co.th