What is Machine Safety?

Manufacturing has changed drastically in a short time with new technologies such as machines that augments worker’s efficiency and manpower. Machines can help improve production efficiency in the process line, however, due to moving parts, sharp edges, and hot surfaces, it might be dangerous for workers to operate around them. Machines can cause workplace injuries such as crushed or amputated fingers or hands, blindness, burns and so on. Thus, it is crucial that a factory has a safeguard workers from workplace injuries and one such term coined with the safety of workers is MACHINE SAFETY and MACHINE GUARDING.

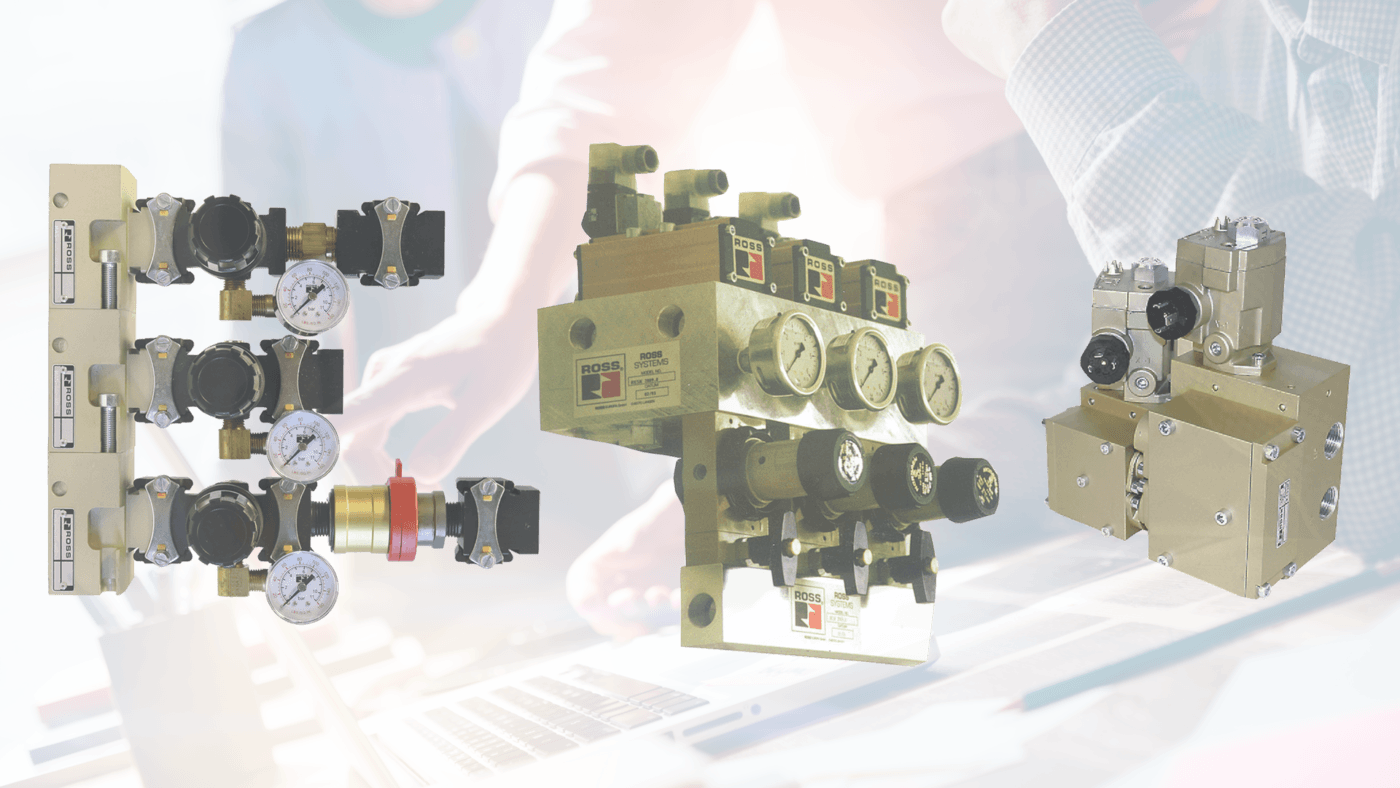

The machine safety market is segmented by implementation of individual and embedded components, geography, end-user industry, and components such as emergency stop devices, safety interlock switches, and presence detection safety sensors. ROSS Controls® has been designing and supplying the “industry standards” of safety products for pneumatic energy isolation (LOTO) and control reliable double valves for the metal forming industry for clutch/brake applications and the general manufacturing sector for decades. ROSS designed and supplied valves for energy isolation and mechanical press clutch/brake control valves that were later widely recognized as aids to companies for regulatory compliance in non-press applications.

These are some of the most safety critical pneumatic valve applications in manufacturing today, and ROSS has been there to help make jobs safer for workers, helping to protect our customers’ investments in machinery, and increase productivity.

ROSS® Safety Valves

press control pneumatic safety hydraulic safetyROSS® Safety Applications

Energy Isolation

Pneumatic Energy Isolation is achieved with a manually operated valve in a system that stops the further input of a specific energy. Isolation devices for pneumatic systems are generally used in conjunction with a bleed device that is used to dissipate energy that may be downstream of the isolation device. In most pneumatic devices, the isolation device and bleed device are combined into a single component that shuts off the supply of pneumatic energy and also exhausts downstream pneumatic energy from as far downstream as possible.

Safety Exhaust

A safe manufacturing environment must include a healthy respect for the, sometimes dangerous, interactions between man and machinery. This is reflected in the evolution in the once simple and now sophisticated safety-related valves. In pneumatic and hydraulic circuits where the primary concern is the removal of pneumatic or hydraulic energy from a device or system, additional dump or exhaust valves are typically incorporated specifically for this function. The function of a Safety Exhaust Control Valve mimics that of an electrical control relay and is subject to the same rules for classifying safety integrity.

Safe Cylinder Return

ROSS CrossMirror Double Valves provides control reliable cylinder/actuator control resulting in increased safety and savings. Typical safety designs look to remove the air to a machine or zone. If there is a single actuator hazard it can be controlled with a safety control valve providing point of use control. This provides not only safety but offers savings in air consumption and eliminates any downtime due to recharging the system. The CrossMirror valve is internally self-monitored and requires no additional valve monitoring controls. It also includes a status indicator switch (ready-to-run) to inform machine controller of the valve condition. This switch must be integrated into machine controls in order to prevent a run signal until the valve fault is cleared.

Load Holding

Cylinder applications must take into consideration what happens with the loss of air pressure and how will impact the safety of both man and machine. This is especially important with vertical cylinder applications. Pilot Operated Check Valves, otherwise known as PO Checks, are used wherever a high-flow or remotely controlled checking function is needed to provide cylinders to automatically stop in the event of the loss of electrical power or system air.

สำหรับข้อมูลเพิ่มเติม โปรดติดต่อเรา:

โทร: 02-384-6060 | ไลน์: @flutech.co.th | อีเมล: [email protected] | เฟสบุ๊ค: @flutech.co.th | เว็บไซต์: https://flutech.co.th