AIRSWEEP® SOLVES A 4-YEAR-OLD MATERIAL FLOW PROBLEM IN JUST 2 WEEKS

Asphalt is made from sands, aggregates, sands, and asphalt cement. The materials have a tendency to conglomerate and compact in the storage silos. With asphalt’s nature, flow aids or material activation systems like pneumatic vibrators pack the material even more. If a silo gets clogged or blocked, production slows down immediately and an array of problems and issues become inevitable.

THE PROBLEM

HAMMERS ARE A SAFETY RISK

Over the weekend, when a Mexico plant of a regional manufacturer of asphalt products was unstaffed, the asphalt materials would settle completely. When workers returned on Monday, they had to climb seven meters down into the dark silo, and clear thick layers of compacted material just to get the factory running again. Despite having electric vibrators, plant workers still had to hit silos with a hammer or climb in the vessel to clean it.

This “Monday Morning Cleanup” wasted the plant’s time, money, and most importantly, put their workers at risk. The company wanted to eliminate the hazardous factors that risk employees’ safety, the wasted time, and the lost money by trading the hammers for an effective and reliable material flow aid system – AIRSWEEP®.

THE SOLUTION

AIRSWEEP® GIVES EXTRA POWER AND GO THE EXTRA MILE

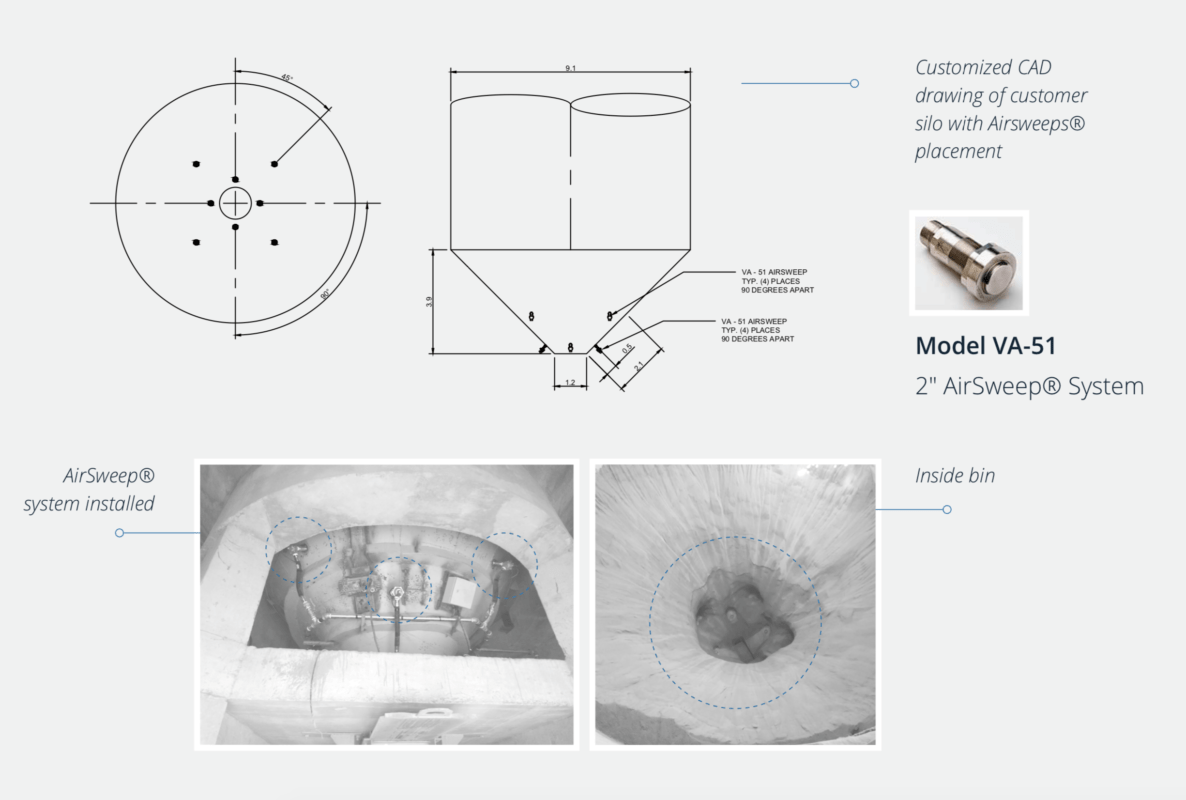

The system was customized according to the plant’s process and vessel size. The AirSweep® Model VA-51 unit was ideal for large silos, and had the power to activate 6 to 8 feet (1.8 m to 2.4 m) of heavy material with one pulse. Eight units were positioned accordingly to ensure first-in/first-out on-demand flow.

The cones were made of concrete, but an engineer visited the site and quickly resolved the issue. After inspecting the vessel, he recommended adding a metal sheet – a cheap, fast and effective workaround. After two weeks, the plant’s problem of asphalt silo clogging of four years was resolved in just two weeks.

THE RESULTS

REDUCED BUILD-UP, NOISE, AND ENERGY CONSUMPTION

Reference: Control Concepts USA

สำหรับข้อมูลเพิ่มเติม โปรดติดต่อเรา:

โทร: 02-384-6060 | ไลน์: @flutech.co.th | อีเมล: [email protected] | เฟสบุ๊ค: @flutech.co.th | เว็บไซต์: https://flutech.co.th