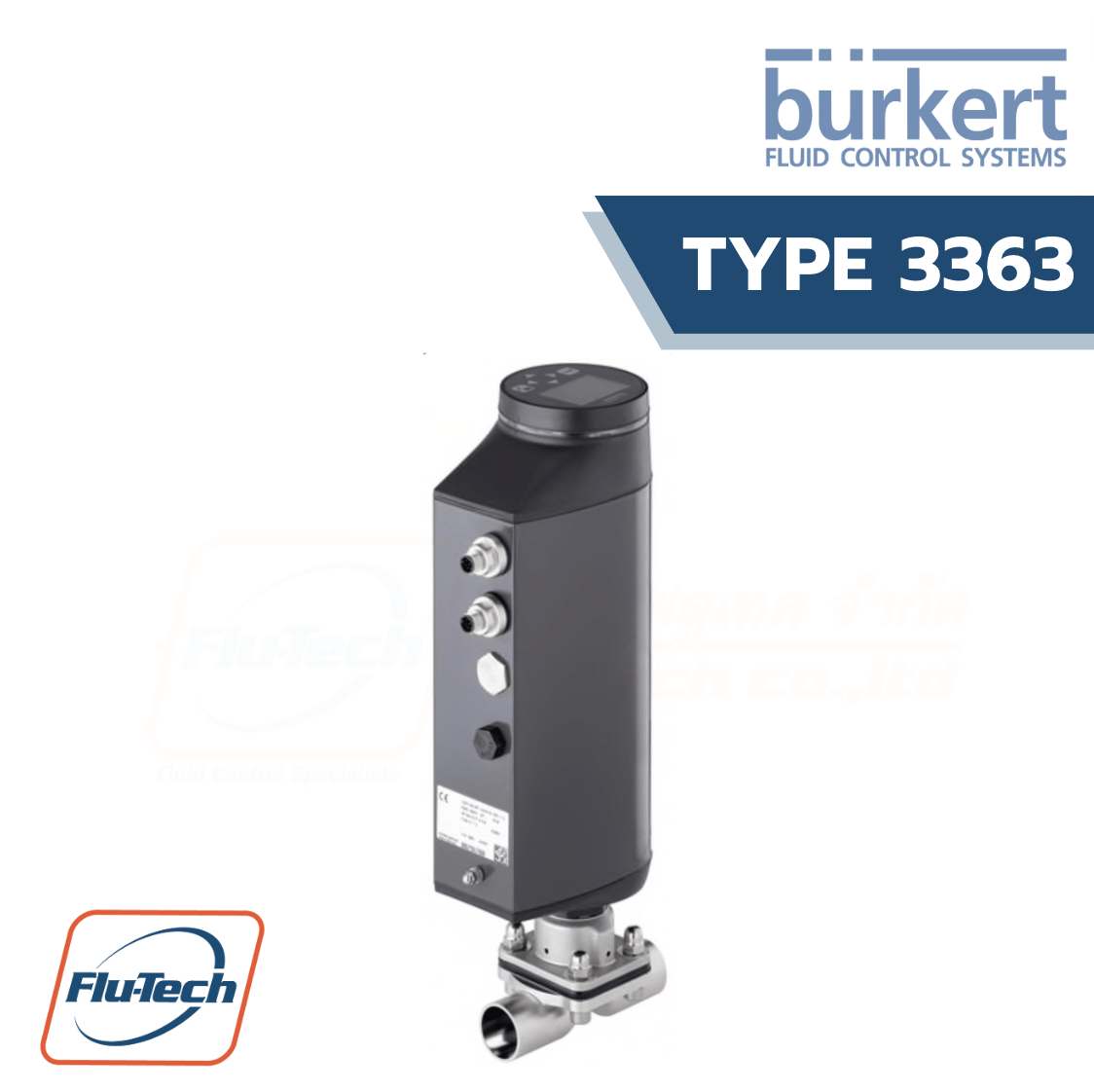

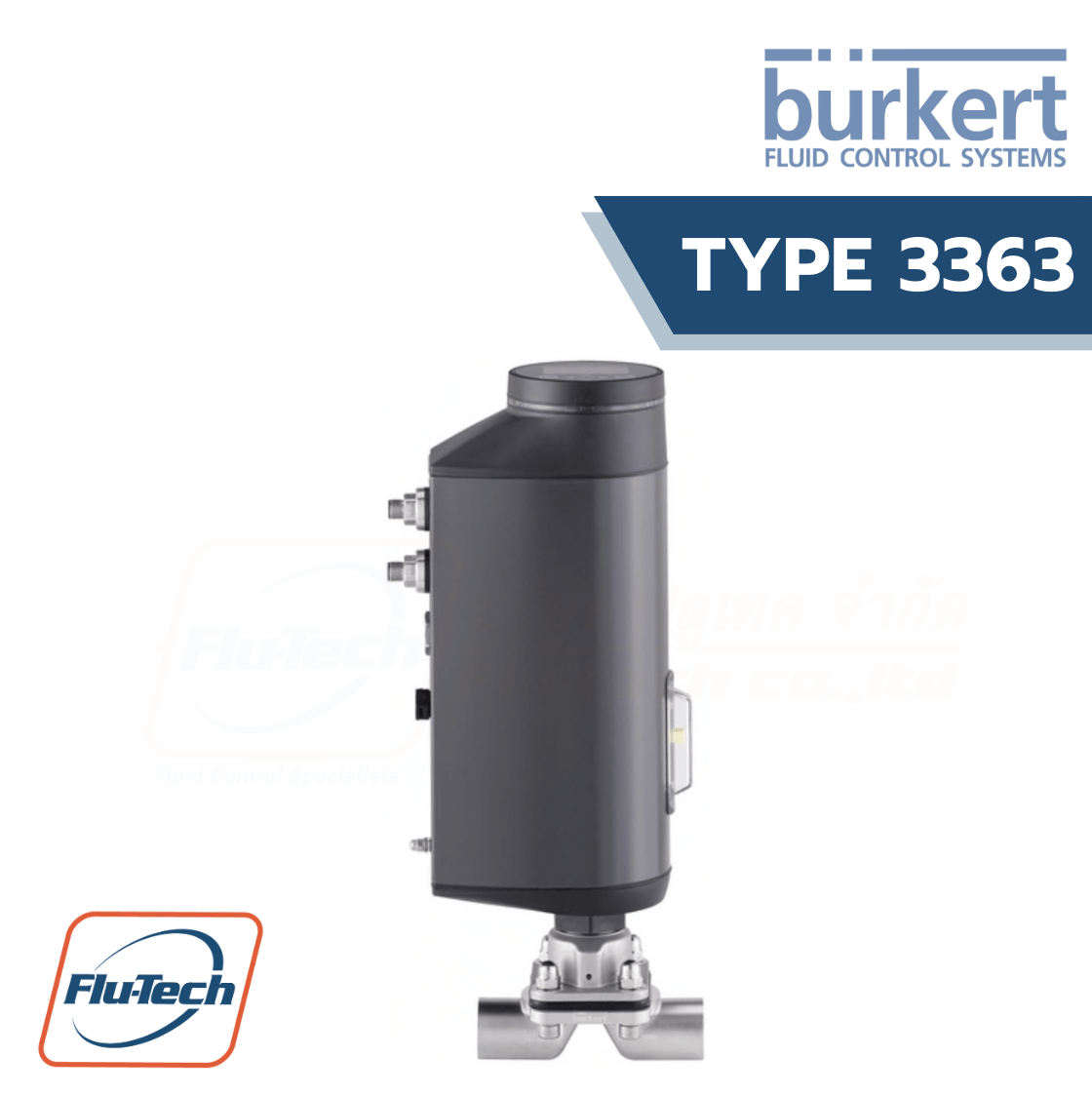

2/2 way diaphragm valve with (Positioner) electric linear actuator (Type EVA)

The externally controlled diaphragm valve Type 3363 consists of an electrically controlled linear actuator (positioner), of a diaphragm and a 2 way valve housing. The electric actuator with recirculating ball screw ensures use under hygienic or aggressive environmental conditions. The flow-favorable and dead space-free valve housings enable high flow values and a wide range of possible uses. In the event of a power failure, the safety position is guaranteed by an optional energy storage device. The position is displayed by means of a 360° LED light ring. To protect the diaphragm the actuator has a drive force adjustment. A correspondingly high IP protection IP65/IP67 ensures adequate splash protection. In addition to a fast actuating speed of 1.5 to 4.5 seconds, the actuator is also equipped with a mechanical position indicator and a corresponding explosion protection ATEX/II 3G Ex ec IIC T4 Gc/II 3D Ex tc IIIC T135 °C Dc.

Downloads

Data Sheet User ManualBURKERT TYPE 3363 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

|

Dimensions

|

Detailed information can be found in chapter “4. Dimensions” on page 8.

|

| Forged body (VS) material |

Forged stainless steel 316L/1.4435/BN2, Fe <0.5%/C ≤0.03%

|

| Tube valve body (VP) material | Stainless steel 316L/1.4435/BN2 |

| Cast body (VG) material | Cast stainless steel 316L/1.4435 |

| Plastic body (PV; PD; PP) material | PVC (PVC-U); PVDF; PP |

| Diaphragm material |

EPDM (AD), PTFE/EPDM (EA), advanced PTFE/EPDM (EU), Gylon®/EPDM laminated (ER)

|

| Diaphragm size | 8…40; for plastic body 15…40 |

| Forged body (VS) standard surface quality |

Internal electrically polished: Ra ≤ 0.38 μm (NO17) (ASME BPE SF4/DIN HE4) (external forged surface electrically polished) / Internal mechanically polished: Ra ≤ 0.5 μm (NO14) (ASME BPE SF1) (external forged surface)

|

| Tube valve body (VP) standard surface quality | Internal electrically polished: Ra ≤ 0.38 μm (NO17) (ASME BPE SF4/DIN HE4) External glass bead blasted: Ra ≤ 1.6 μm (NO01) Internal glass bead blasted: Ra ≤ 1.6 μm (NO05) |

| Cast body (VG) standard surface quality | Internal electrically polished: Ra ≤ 0.6 μm (NO16) (ASME BPE SF6) (external cast surface electrically polished) Internal mechanically polished: Ra ≤ 0.76 μm (NO06) (ASME BPE SF3/DIN H2) (external cast surface) |

| Safety setting in case of power failure | With SAFEPOS energy-pack: open, closed or freely programmable / Without SAFEPOS energy-pack: blocked in last position |

| Lifelong energy storage SAFEPOS energy-pack |

Up to 10 years (depending on operating conditions)

|

| Controller version | Positioner or process controller |

| Dead band | Min. 0.4% |

Performance Data |

|

|

Closing time

|

< 1.5 sec. to 4.5 sec. depending on diaphragm size

|

| Traverse speed | 4 mm/s |

Electrical Data |

|

|

Operating voltage

|

24 V DC ±10% (max. residual ripple 10%)

|

| Electronic without actuator | Min. 2 W, max. 5 W |

| Protection class | IP65/IP67 |

| Duty cycle | 100% |

| Operating current | Max. 3 A including actuator at max. load and charging current of the optional SAFEPOS energy-pack (charging current approx. 1 A) |

|

Standard signals (analogue) communication and control

|

Set point: 0…20 mA, 4…20 mA, 0…5 V, 0…10 V / Actual value optional |

| Fieldbus (digital) communication and control | EtherNet IP, Modbus TCP, PROFINET (optional) and CANopen |

Medium Data |

|

|

Operating medium

|

Neutral gases and fluids, highly purified, sterile, aggressive or abrasive medium (See Chemical Resistance Chart) |

|

EPDM (AD)

|

– 10…+ 143 °C (steam sterilisation + 150 °C for 60 min)

|

| PTFE/EPDM (EA) |

– 10…+ 130 °C (steam sterilisation + 140 °C for 60 min)

|

| Advanced PTFE/EPDM (EU) |

– 5…+ 143 °C (steam sterilisation + 150 °C for 60 min)

|

| GYLON®/EPDM laminated (ER) |

– 5…+ 130 °C (steam sterilisation + 140 °C for 60 min)

|

| Plastic body |

See “3.2. Pressure temperature diagram for plastic body” on page 6

|

Process/Port Connection & Communication |

|

|

Port connection size

|

DN 06…DN 40 (1⁄8″…11⁄2″)

|

|

Welded connection for stainless steel body

|

DIN EN ISO 1127/ISO 4200/DIN 11866 series B / DIN 11850 series 2/DIN 11866 series A/DIN EN 10357 series A / ASME BPE/DIN 11866 series C |

| Clamp connection for stainless steel body | DIN 32676 series A (DIN pipe) / DIN 32676 series B (ISO pipe) / ASME BPE |

|

Spigot connection for plastic body

|

DN 15…DN 40

|

| True union for plastic body | DN 15…DN 40 |

| Loose flange for plastic body | DN 15…DN 40 |

Electrical Connection |

|

|

Actuator

|

Terminal strip with cable gland, 2 x M20 or / 2 M12 circular plugs, 5 pin and 8 pin |

| Fieldbus gateway | 2 M12 circular sockets, 4 pin (only with Industrial Ethernets) |

Approvals and Certificates |

|

|

Ignition protection class

|

II 3G Ex ec IIC T4 Gc / II 3D Ex tc IIIC T135 °C Dc |

Environment and Installation |

|

|

Installation position

|

As required, preferably with actuator upright

|

|

Vibration, sinusoidal resistance

|

5 g (IEC 60068-2-6 Test Fc) |

| Shock, mechanical resistance | 50 g (IEC 60068-2-27 Test Ea) |

|

Ambient temperature

|

– 10 °C…+ 65°C4.) (without display) |

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th