A POWERFUL SIGNAL FOR SAFE CONTROLLING

COOPERATION WITH HUNTSMAN

The Huntsman textile chemicals company manufactures finishing chemicals for clothing, home textiles, technical textiles and digital textile printing at its factory in Langweid am Lech. Bürkert and Huntsman have been working together closely for many years, a cooperation that began in 1982 when this location was constructed. As part of a modernization programme, Bürkert’s fluidics experts were commissioned to design a decentralized solution for controlling process valves with a view to replacing the old valve control systems.

FOCUS ON SAFE TECHNOLOGY

Production facilities in which flammable and explosion-risk materials are used require comprehensive maintenance. Safety-related technology is at the focus here. At Huntsman, plant modernization is carried out in rotation and according to the planned overhaul intervals. To this end, individual plant sections such as reactors, tanks and pressure vessels are taken out of operation and reconditioned to make sure that they are technically up to date. Special chemicals are produced in batches, so overhauls can only be scheduled between batches. The first Bürkert products were installed at Huntsman as early as 1982, and some of them are still in operation today. In 2004, Huntsman and Bürkert cooperated once again to equip four new systems with intrinsically safe solenoid valve cabinets and valves. Finally, a plant producing 30 different products was modernized in 2015 and provided with a new enamelled boiler. At this point the outdated control technology was also replaced, and a new, decentralized process control system and a new PLC level were introduced.

Did you know?

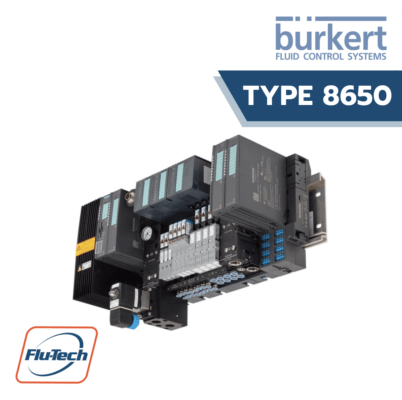

Bürkert’s Type 8650 valve island is designed in such a way that valves and electronics modules can be replaced quickly and without interrupting system operation, i.e. while it is under pressure and electrically live. Integrated non-return valves ensure better process reliability.

MORE THAN JUST A CONTROL CABINET

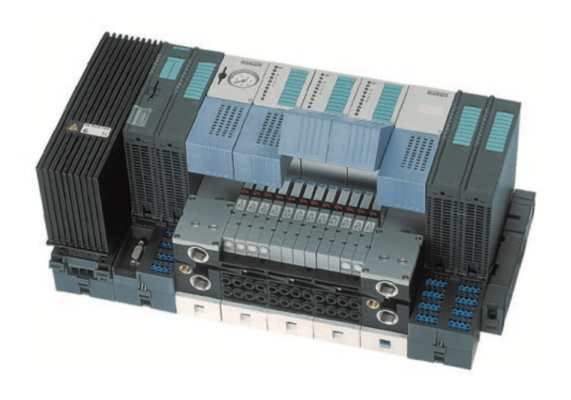

The control cabinet system solution for the pneumatic automation system of the process-related plant sections means that, in combination with the newly introduced Emerson DeltaV process control system and the WAGO PLC level, the plant engineering is now state of the art. As part of the modernization programme for the boiler plant, a completely prefabricated, ready-to-connect and ATEX certified control cabinet system solution for the field automation was in-stalled, including failsafe and intrinsically safe signals. This system solution comprises the Type 8616 control cabinet (ATEX Zone 1 approved), with a Siemens decentralized ET 200iSP peripheral system and a Type 8640 valve block with Type 6518 safety valve and the Type 8650 valve island. This solution takes up considerably less space and is easier to install. In addition, the customer commissioned Bürkert to set up a safety-related switchover system using pneumatic step chains that allows the system to switch over to an external pressure accumulator if the compressed air or electricity supplies fail.

The size of the valves in the old Bürkert cabinets meant that only a limited number of pneumatic signals were possible. The “EX-e” wiring was also a great deal more complicated.

The new solution greatly reduces the space and installation work required, because only the electricity supply and Profibus cable need to be connected.

HOT SWAP WITHOUT DOWNTIMES

The signal inputs and outputs of the ET 200iSP and the valves used in the control cabinet are intrinsically safe. This means that maintenance can also be carried out during operation and under ATEX conditions. The high plant availability is optimized through the pneumatic P-shut-off in the base valve block. So in addition to the electrical hot swap, it is also possible to carry out a pneumatic hot swap.

FLEXIBILITY IN THE CONTROL CABINET

The Type 8650 valve island is used for controlling the pneu- matic functions and is also ATEX certified. Thanks to the modular design of its pneumatic and electrical interfaces, it is capable of coping with complex control tasks. By apposing the pneumatic modules with varying numbers of valves it is possible to set up 4 to 64 valve functions on a valve island.

“We supply everthing from a single source for Huntsman! Engineering, procurement, assembly, documentation and certification of entire control cabinets. Of course, this includes all the individual customer requirements, bearing ATEX standards and guidelines in mind right from the start. Where can you get more service than that into a system solution?”

– Heiko Kurtz, Field Segment Manager ATEX-Solutions at Bürkert

Reference: Bürkert

For more information:

Tel.: 02-384-6060 | Line: @flutech.co.th | Email: [email protected] | Facebook: @flutech.co.th | Website: https://flutech.co.th