What is a Solenoid Valve?

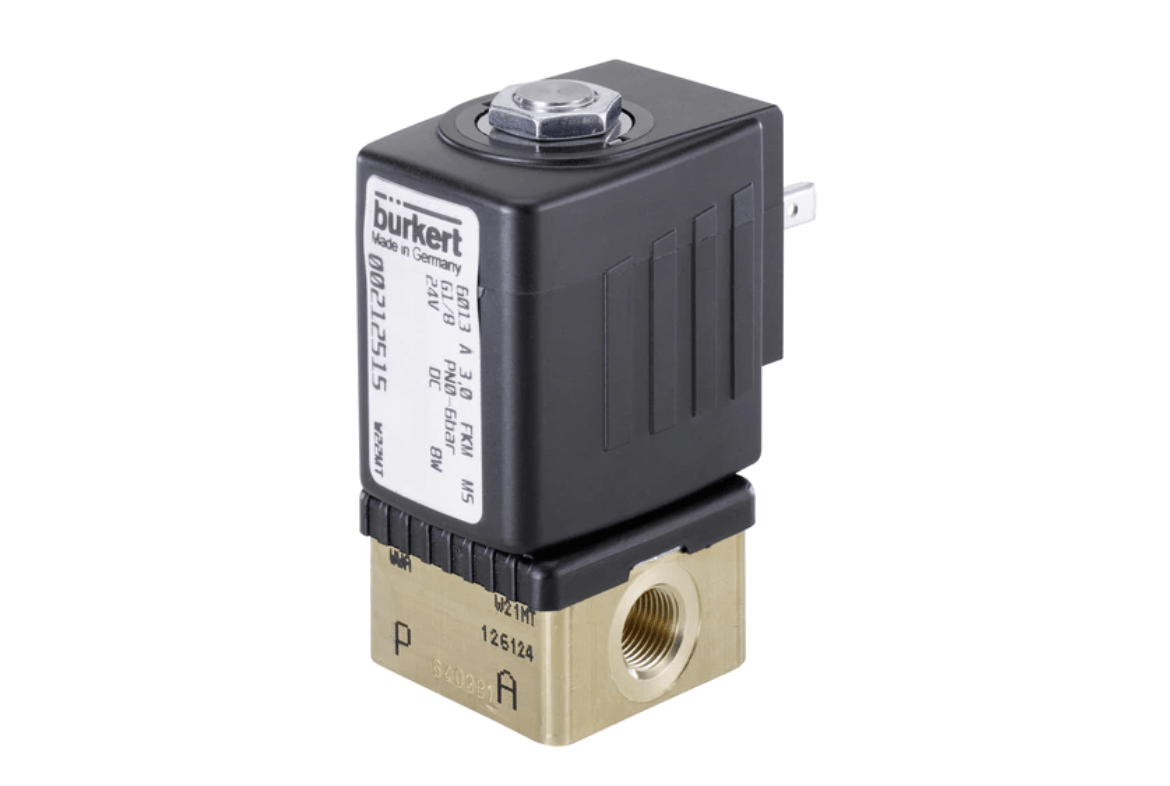

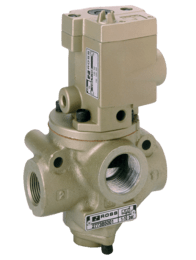

BURKERT Type 6024 – Direct-Acting 2-Way Low Differential Pressure Solenoid Control ValveA solenoid valve is an electrically controlled valve. The valve features a solenoid, which is an electric coil with a movable ferromagnetic core (plunger) in its center. In the rest position, the plunger closes off a small orifice. An electric current through the coil creates a magnetic field. The magnetic field exerts an upwards force on the plunger opening the orifice. This is the basic principle that is used to open and close solenoid valves.

How does a Solenoid Valve Work?

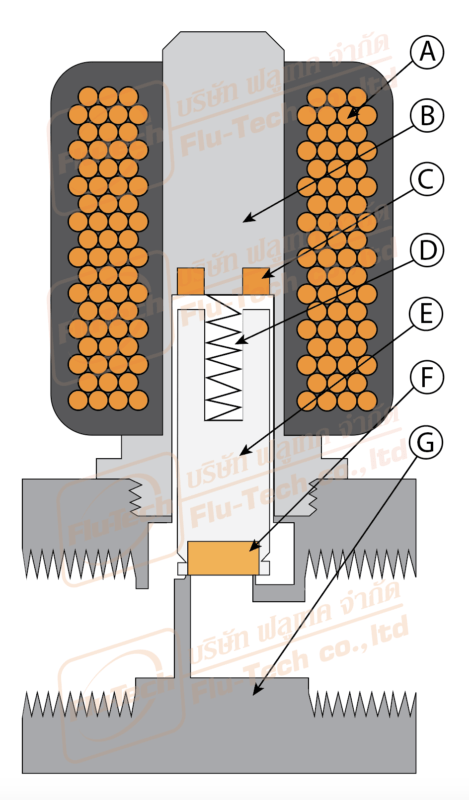

A solenoid valve consists of two main components: a solenoid and a valve body (G). A solenoid has an electromagnetically inductive coil (A) around an iron core at the center called the plunger (E). At rest, it can be normally open (NO) or normally closed (NC). In the de-energized state, a normally open valve is open and a normally closed valve is closed.

When current flows through the solenoid, the coil is energized and creates a magnetic field. This creates a magnetic attraction with the plunger, moving it and overcoming the spring (D) force. If the valve is normally closed, the plunger is lifted so that the seal (F) opens the orifice and allows the flow of the media through the valve. If the valve is normally open, the plunger moves downward so that the seal (F) blocks the orifice and stops the flow of the media through the valve. The shading ring (C) prevents vibration and humming in AC coils.C

Solenoid valves are used in a wide range of applications, with high or low pressures and small or large flow rates. These solenoid valves use different operating principles that are optimal for the application. The three most important ones are explained in this article: direct acting, indirect acting, and semi-direct acting operation.

Circuit Functions of Solenoid Valves

Solenoid valves are used to close, open, dose, distribute or mix the flow of gas or liquid in a pipe. The specific purpose of a solenoid valve is expressed by its circuit function. The circuit functions of a solenoid valve is classified into two functions: 2-Way and 3-Way solenoid valves.

2-Way

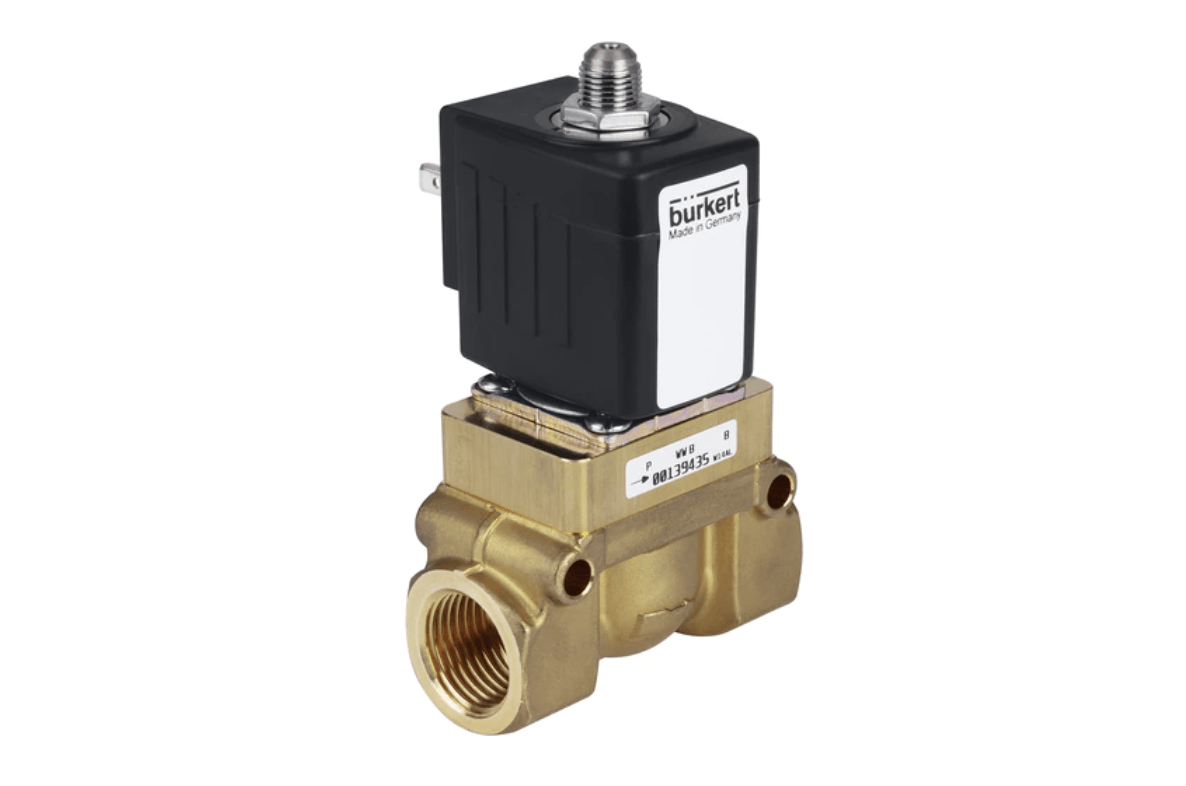

A 2-way solenoid valve has two ports, an inlet and an outlet. Flow direction is critical to ensure proper operation, so there is typically an arrow indicating the flow direction. A 2-way valve is used to open or close the orifice. For more information about 2-Way solenoid valves, please click here.

3-Way

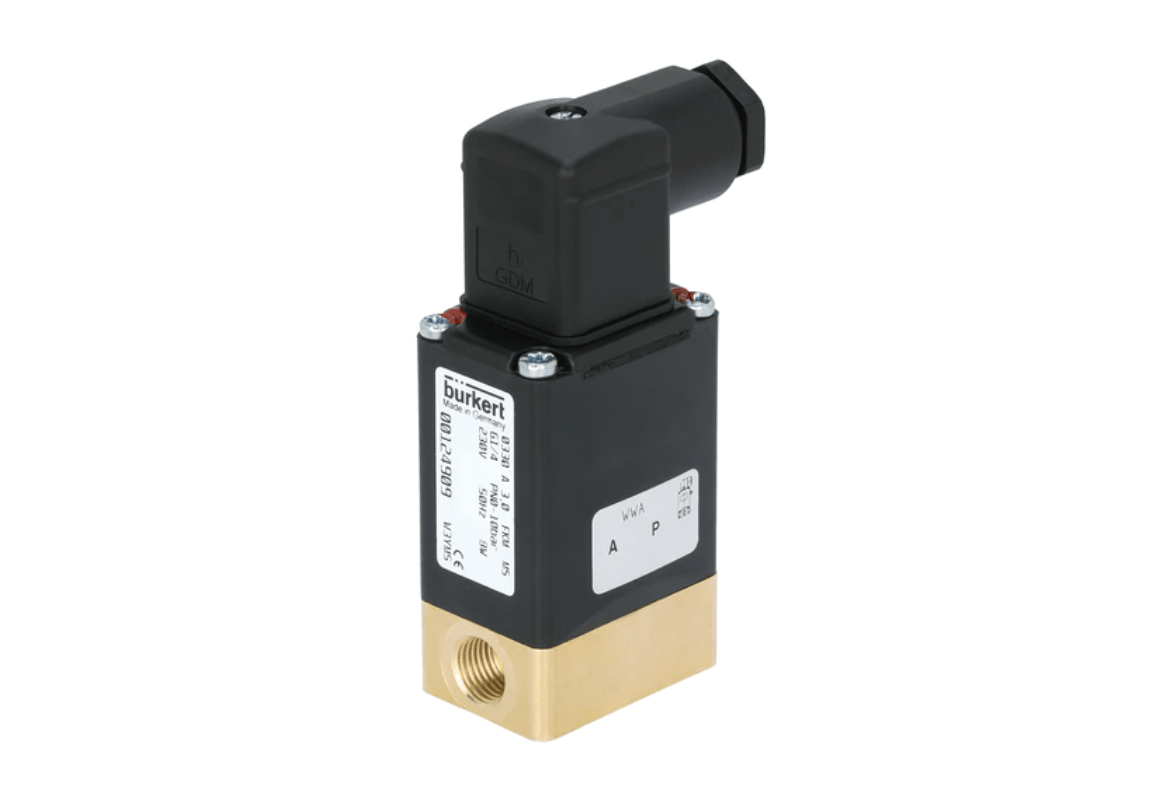

A 3-way valve has three connection ports. Typically, it has 2 states (positions) it can be in. So, it switches between two different circuits. A 3-way valve is used to open, close, distribute, or mix media. For more information about 3-Way solenoid valves, please click here.

Types of Solenoid Valves

- Normally Closed (NC)

For a normally closed solenoid valve, the valve is closed when de-energized and the media cannot flow through it. When current is sent to the coil, it creates an electromagnetic field that forces the plunger upwards overcoming the spring force. This unseats the seal and opens the orifice allowing the media the flow through the valve.

- Normally Open (NO)

For a normally open solenoid valve, the valve is open when de-energized and the media can flow through it. When current is sent to the coil, it creates an electromagnetic field that forces the plunger downwards overcoming the spring force. The seal is then seating in the orifice and closing it, which prevents media from flowing through the valve. A normally open solenoid valve is ideal for applications that require the valve to be open for long periods of time as this is then more energy efficient.

- Bi-Stable

A bi-stable or latching solenoid valve can be switched by a momentary power supply. It will then stay in that position with no power. Therefore, it is not normally open or normally closed as it stays in the current position when no power is applied. They accomplish this by using permanent magnets, rather than a spring.

Working Principles of Solenoid Valves

- Direct Acting

- Indirect Acting (Servo/Pilot Operated)

- Semi-Direct Acting

Solenoid Valves Certificates

- IP Ratings (Ingress Protection): The IP rating of a valve explains its protection to dust and water. For example, IP65 and IP67.

- ATEX Version: Provided for explosion protection.

- UL/UR: Underwriters Laboratories inspects and certifies products with respect to their safety.

- Drinking Water: Ensures it is suitable for drinking water purpose. Common drinking water approvals are.

- Kiwa: Drinking water approval for the Dutch market.

- NSF: Drinking water approval for North America.

- WRAS: Compliance with Water Supply Regulations in UK or Scottish Byelaws for material safety and mechanical testing.

KTW: Approval for plastics and non-metallic materials for use with potable water in Germany. - Attestation De Conformite Sanitaire (ACS): Drinking water approval for France.

- Watermark: Certification for plumbing and drainage products for sale in Australia and New Zealand.

- FDA: Food and Drug Administration.

- CE Certification: CE certification signifies conformity with high safety, health and environmental protection requirements for all products in the European Economic Area.

- Gas Version: Valves for gas applications have DVGW approval for use in gas burning appliances as automatic shut-off valve.

Solenoid Valves Selection Criteria

- Voltage

- Pressure

- Temperature

- Seal Material

- Valve Function

- Operation Type

- Response Time

- Housing Material

- Degree of Protection

- Certifications/Approvals

- Type of Solenoid Valve (2-Way or 3-Way)

Reference: Tameson, Ross, Burkert

สำหรับข้อมูลเพิ่มเติม โปรดติดต่อเรา:

โทร: 02-384-6060 | ไลน์: @flutech.co.th | อีเมล: [email protected] | เฟสบุ๊ค: @flutech.co.th