เวอร์ชั่นภาษา (TH)

What are Proteins?

Proteins are large, complex molecules that play many critical roles in the body. They do most of the work in cells and are required for the structure, function, and regulation of the body’s tissues and organs.

Protein is found throughout the body—in muscle, bone, skin, hair, and virtually every other body part or tissue. It makes up the enzymes that power many chemical reactions and the hemoglobin that carries oxygen in your blood. At least 10,000 different proteins make you what you are and keep you that way. One needs protein in your diet to help your body repair cells and make new ones. Protein is also important for growth and development in children, teens, and pregnant women.

Being crucial, one must consume the sufficient amount a day by ingesting food or beverages like milk, eggs, chicken breast, or yoghurt. So how does one know much protein is there in a portion of what they are consuming?

Protein Measurement

In order to determine the quantity of protein in food, it is important to have standardized analytical methods. Several methods exist that are used in different food industries to quantify protein content, including the Kjeldahl, Lowry, Bradford and total amino acid content methods. The correct determination of the protein content of foods is important as, often, as is the case with milk, it determines the economic value of the food product and it can impact the economic feasibility of new industries for alternative protein production.

The type and quality of protein that we consume is important for our general health and wellbeing – Bürkert Type 8098 – FLOWave SAW Flowmeter can offer a smooth flow measurement to ensure the correct protein content.

Make Way for Proteins

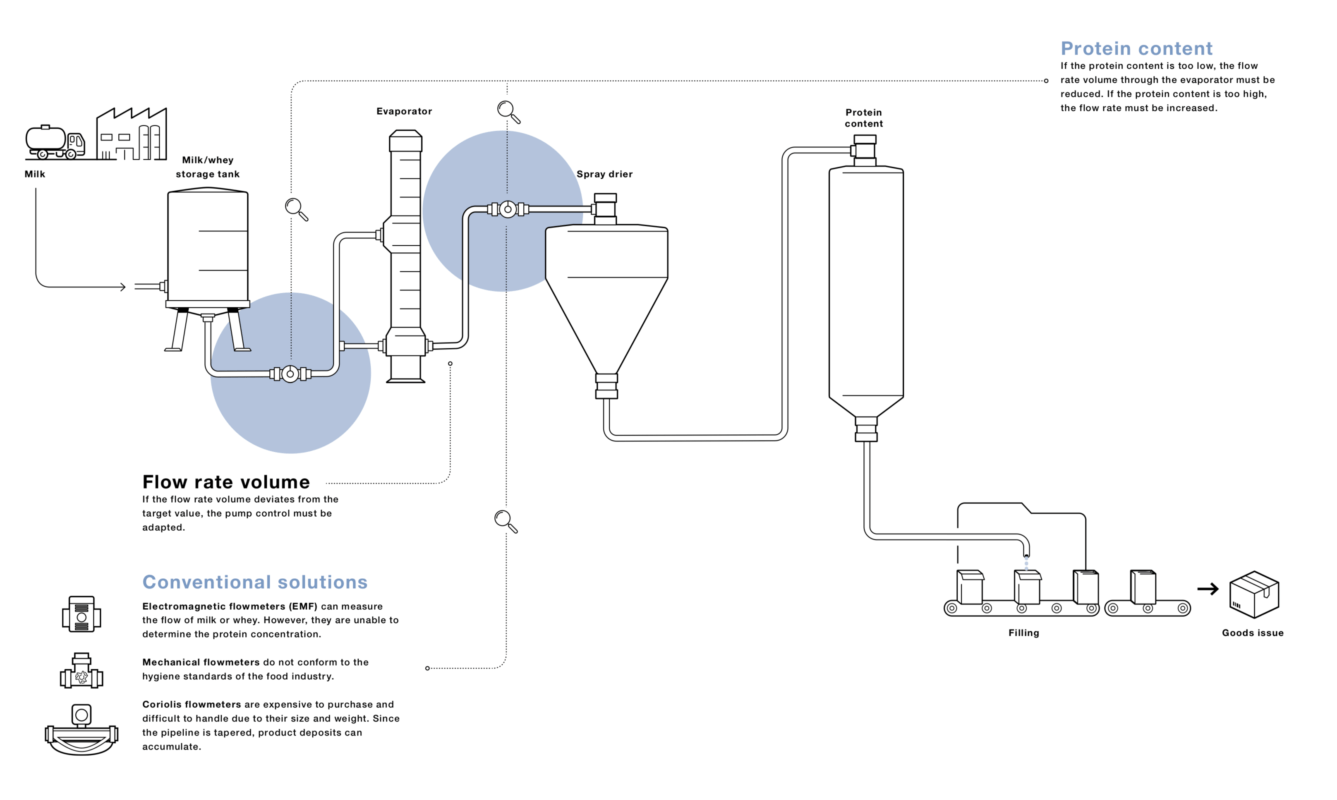

During the industrial production of milk or whey powder, the protein is separated from the raw milk or whey. Whether it is baby food or a fitness drink: The ability to produce a specific volume of powder with the required protein content is critical for plant operators.

A dairy converts milk and whey into powder. The end product must have a defined protein content.

The challenge: The separation process influences the protein content. If this content is too low, separation must continue until the correct value is reached. If the protein content is too high, the system may become clogged.

Is the Protein Content Correct?

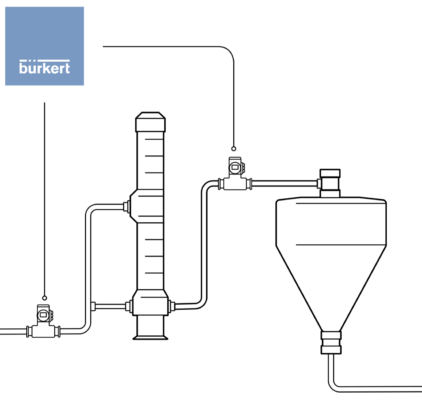

During the production of milk and whey powder, your plant must measure and control the volume flow through the evaporator or filter precisely – because the protein concentration depends on it. A flow meter that measures more than just the flow rate offers added value.

Flow Measurement with SAW Technology

Hygiene is particularly important during the production of dairy products. FLOWave gives you a compact solution that measures the flow under completely hygienic conditions. Thanks to innovative SAW technology, the flowmeter dispenses with sensor elements in the measuring tube. No parts in the measuring tube means: no deposits, no material incompati bility, no maintenance, no pressure drop and easy cleaning.

A Compact All-Rounder

FLOWave is more than just a flowmeter. The sensor not only measures the flow rate, but also the temperature, density factor and acoustic transmission factor of your liquids. This ensures that the required protein content is reached. This is a gain for your production plant: Your plant operates with maximum reliability.

Maximum Precision

FLOWave measures the volume flow independently of the conductivity of the medium with an accuracy of 0.4 % of the measured value, the accuracy for the temperature is ≤ 1 °C.

Meets the Highest Hygiene Requirements

FLOWave dispenses with sensors in the measuring tube that come into contact with the medium. It therefore measures the flow under completely hygienic conditions. This is confirmed by various certificates (ASME BPE, 3A and EHEDG).

Fast Startup and Easy Operation

The high-resolution 2.4“ display offers flexible operation with intuitive, graphic user guidance. Freely definable measured value designations and the optional display of one to four measured values, a trend curve and the parameterization interface enable an individually coordinated display. The WiFi module allows remote access to measurement parameters via web browser.

Constant Processes and Product Quality

The “density factor” and “acoustic transmission factor” functions enable FLOWave to detect different protein contents quickly and reliably. This reduces waste and costs while increasing productivity.

Easy to Handle and Install

The compact and lightweight flowmeter fits into every system and is easy to install. At two inches in size, a FLOWave device weighs just 3.4 kg – compared to the 70 kg heavy, two-inch Coriolis system.

Fit for the Future

FLOWave devices utilise the Bürkert device platform EDIP. EDIP stands for “Efficient Device Integration Platform”. It considerably simplifies the handling of the devices and helps to integrate them quickly into an existing fieldbus system. In short: EDIP is part of our contribution to Industry 4.0.

Protein Concentration at a Glance

FLOWave determines the density factor, the acoustic transmission factor and the temperature. From these measurements, the controller or the gateway module ME43 calculates the current protein content. If the plant is in danger of becoming clogged, the acoustic transmission factor comes into play by revealing differences in the flow characteristics of the protein solution. The more solids in the liquid, the more viscous the flow. FLOWave reports these types of variations and uses continuous inline measurement to guarantee consistent product quality.

How does the acoustic transmission factor work?

This measured variable indicates the attenuation of the surface acoustic waves as they propagate inside the sensor tube. It is equivalent to the turbidity measure- ment. The acoustic transmission factor could also be described as acoustic turbidity. It is mainly influenced by bubbles and solids in the liquid.

Pure water has a density factor of 1,000 and an acoustic transmission factor of 100%. In milk or whey, the density factor increases with a higher protein content. At the same time, the acoustic transmission factor decreases as more protein increases the attenuation of the surface acoustic waves.

SAW stands for Surface Acoustic Waves. These occur in the nature, e.g. during seismic activities. Burkert harness the effect into the patented SAW technology for inline measurement.

Reference: Burkert, Harvard, MedlinePlus, NCBI

For More Information:

Tel.: 02-384-6060 | Line: @flutech.co.th | Email: [email protected] | Facebook: @flutech.co.th | Website: https://flutech.co.th