Because sterility is non-negotiable – Bürkert working with the Matachana Group, world leader in the manufacture of steam sterilization equipment.

MATACHANA based in Barcelona is one of the world’s most important suppliers of sterilisers and autoclaves. As a valve supplier, Bürkert has been a close partner to the Spanish company for more than 25 years.

“We guarantee our worldwide customers high quality, and this is the reason why Bürkert has been a key and valued partner of choice for more than 25 years.” – Marino Alonso,

Bürkert products are used in the autoclaves to control steam, vacuum and liquids. Matachana also relies on valves from Bürkert in the new steam sterilizer.

Innovative Steam Sterilizer

The Steam Sterilizer Series vSC500/I is a steam sterilizer suitable for use in the biological protection level according to § 10 BioStoffV. The steam steriliser features a state-of-the-art, highly effective control system. A TFT touchscreen with integrated programmable open-loop control (PLC) allows ergonomic access to measured values such as temperature and pressure.

The condensates generated in the chamber and the protective cover during the sterilization process are kept in the lower interior of the chamber. They are sterilised during the cycle with the help of steam pulses. Following the treatment, the condensate can be poured into the discharge outlet under sterile conditions.

Functional design for more performance: Bürkert valves in the steam sterilizer

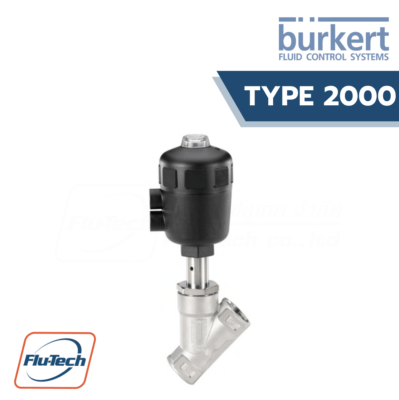

In order to guarantee optimal global service and constant availability, Matachana relies on strong partners with worldwide presence and spare parts availability. Depending on the requirements, valves of Type 2000 or Type 2100 from Bürkert are therefore used in the steam sterilizers.

Type 2000 is an externally controlled angle seat valve. “This solution is ideal for handling dry-saturated steam, two-phase steam and also condensate,” says Luis Teres, Field Segment Manager Hygienic at Bürkert Spain. The proven self-adjusting chevron seal packing gland ensures good sealing for the applied steam overpressure and the vacuum condition. The valves achieve more than three million switching port and are available for almost every pressure and temperature range.

Burkert – Type 2000 – 2/2 way Pneumatically Operated Angle Seat Valve (Type CLASSIC)

จุดเด่นของ Type 2000

- High flow rate

- Long service life

- Robust actuators with modular accessory program

- Stainless steel or gunmetal housing with threaded, clamped or welded connection

Burkert – Type 2100 – 2/2 Way Pneumatically Operated Angle Seat Valve for Decentralized Automation (Type ELEMENT)

จุดเด่นของ Type 2100

- High flow rates

- Long service life

- Suitable for steam

- Easy integration of automation units with ELEMENT

- Flow-optimised stainless steel valve body with sleeve, clamp or weld connection

Angle Seat Valve Controls the Emptying of the Sterilizer Chamber

Among other things, the Bürkert globe valves control the lower connection of the sterilizer chamber. Before the actual sterilization process begins, it must be ensured that all air has been evacuated from the sterilizer and only pure saturated steam remains. The angle seat valve from Bürkert is an ideal solution for monitoring this process. Efficient, effective and reliable sterilization is only possible with pure saturated steam. If porous materials such as operating theatre and laboratory clothing are to be sterilised, even the air trapped in the textile pores must be effectively displaced. Pressure pulsation is the most efficient method for this.

After the pressure pulsation, the heating phase begins, in which pure saturated steam flows into the closed sterilization chamber until over 3,100 mbar and 134 °C are reached. After sterilisation, the pressure is released quickly in order to promote the drying of the sterilised material through the rapid pressure drop. The steam is extracted by a vacuum pump and condenser and condenses into water.

Modular and compact

In addition to the angle seat valves mentioned, Bürkert offers its customers a modular housing with which mixing, distribution or multi-port functions can be implemented in a very compact design. The modular process valve manifold Type 8840 not only replaces the conventional solutions, but also saves piping work and fittings, reduces sealing points and minimizes the installation space.

By combining the Bürkert valves with the valve manifold, many basic functions can be combined. When introduced through a feed line, operating media can be distributed to several consumers. Equally, flows from several consumers can be collected together. Media with different characteristics or compositions such as hot and cold water or different chemicals can be mixed or distributed. Flow, pressure and temperature sensors as well as filters and non-return systems can be integrated directly into the modular process valve cluster.

Burkert – Type 8840 – Modular Process Valve Cluster – Distribution and Collecting

จุดเด่นของ Type 8840 – Modular Process Valve Cluster

- No assembly effort

- Valve cluster ready for installation

- No piping between the valves needed

- Trusted actuators for simple automation

- Compact design without any potential leakage

Ensuring Quality Worldwide

In addition to a compact design, well-functioning logistics are also essential. “We must be in a position to guarantee high quality throughout the world. After all, a failure of fault event at a location far away from Spain means considerable economic damage as well as image loss that should not be underestimated,” explains Marino Alonso, Director of Marketing & Competence Centre at Matachana. He concludes: “Our decision to cooperate with Bürkert is based on the quality, safety and small size of the products.”

For more information:

Tel.: 02-384-6060 | Line: @flutech.co.th | Email: [email protected] | Facebook: @flutech.co.th | Website: https://flutech.co.th