Valves and solenoid valves poppet system Series T772-773

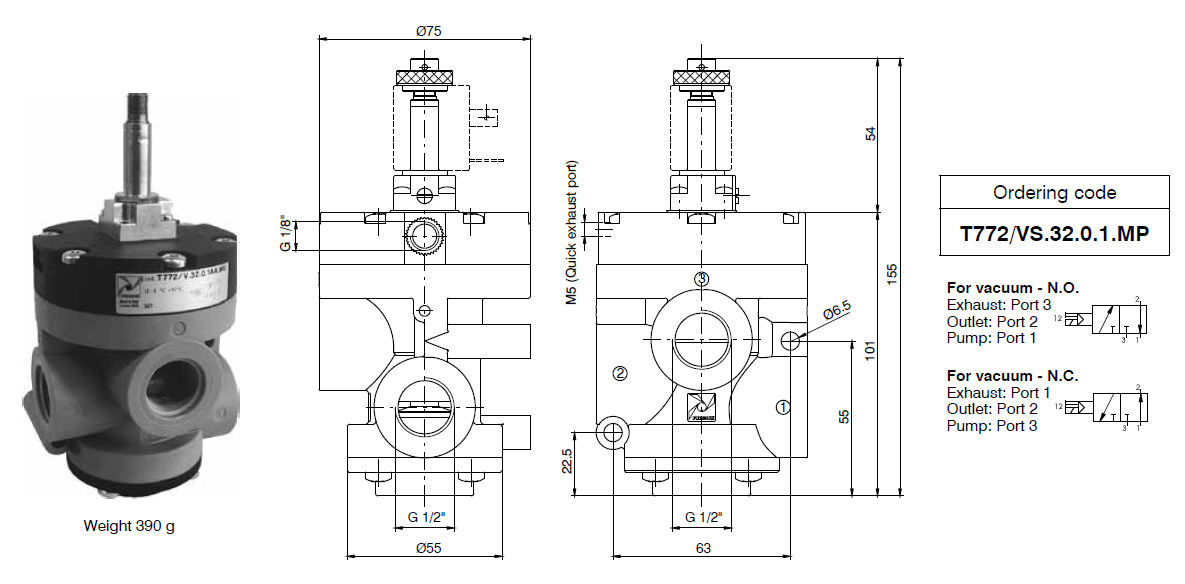

SOLENOID-SPRING-SELF FEEDING – T772/VS.32.0.1.MP

Valves and solenoid valves poppet system G1/2 ”and G3/4” made of high resistance thermoplastic material.

The use of thermoplastic materials has made possible to obtain significantly reduced weights respect to the zamak version and, most importantly, a cost optimization.

The use of a rolling diaphragm in place of the traditional piston, allowed to eliminate friction and wear on the seal. Except for the versions with an external vacuum supply and normally open self feeding vacuum. There is an additional seal provided on the piston which isolates the diaphragm connection 3 this makes it possible to improve the functionality of the valve.

For versions with microsolenoid internal or external supply, there is a fast discharge system incorporated in the operator, which reduces the response time for repositioning the valve by 60%.

The MP version of the solenoid actuator requires an external air or vacuum supply. The MV version uses a self feeding vacuum.

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

Construction characteristics

Body, operator and end cover | High resistance technopolymer |

Seals and poppets | Oil resistant rubber (NBR) |

Piston and shaft | Acetal resin |

Springs | AISI 302 stainless steel |

Diaphragm | Oil resistant rubber (NBR) |

Operational characteristics

Operational characteristics | |

Fluid | Vacuum |

Minimum piloting pressure (bar) | 2,5 |

Temperature °C | -5 ... +50 |

Orifice size (mm) | 15 |

Working port size | G1/2” |

Pilot port size | G1/8” |

Response time according to ISO 12238 energised (ms) | N.C. = 43 - N.O. = 25 |

Response time according to ISO 12238 de-energised (ms) | N.C. = 37 - N.O. = 42 |

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th

You must be logged in to post a comment.