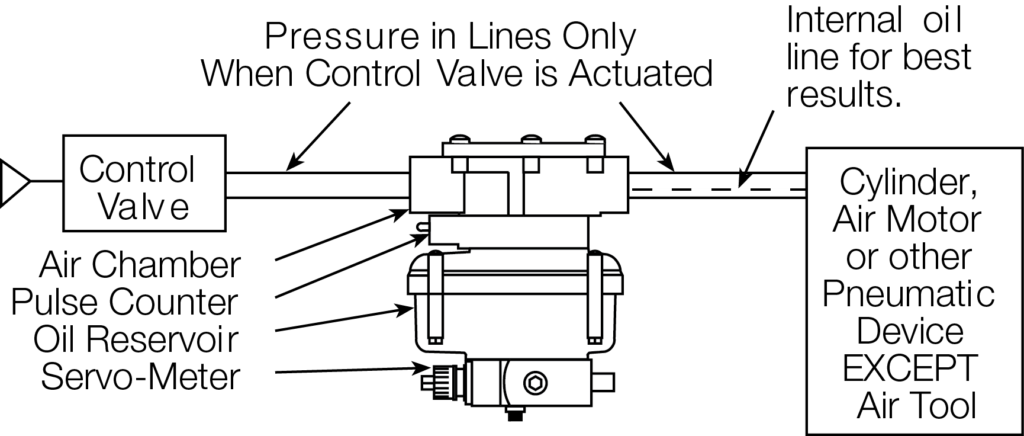

The Downstream Injection Lubricator is specifically designed to overcome the shortcomings of the conventional mist lubricator installed upstream of a control valve. Laboratory and field tests have shown that a mist lubricator installed in the conventional manner results in much of the lubricating oil being exhausted to atmosphere through the exhaust port of the control valve. Oil that passes through the valve tends to coalesce and cling to the wall of the air line where it simply moves back and forth with each valve cycle.

The SERV-OIL downstream injection lubricator eliminates these shortcomings. It is installed downstream of the control valve and uses a small nylon line to carry the lubricant right to the desired lubrication point. This assures dependable

lubrication for cylinders, air motors, or other pneumatic equipment.

The downstream injection lubricator is not designed to work with air tools.

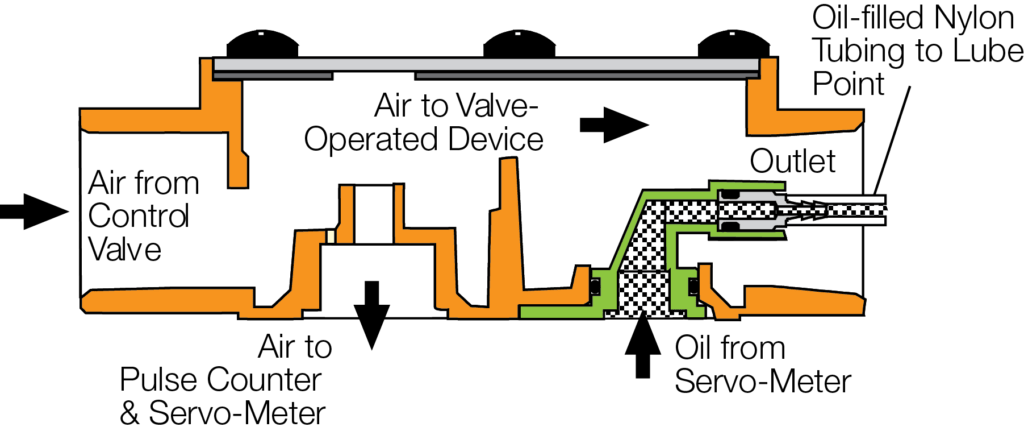

Pulse Counter: When the air tool is triggered the pulse counter receives an air signal from the flow valve. A three position switch on counter is set to allow air signal to proceed to the Servo-Meter on every cycle, every 5th cycle or every 10th cycle. This is one of the means of controlling the amount of lubrication that will be supplied to the air tool.

Servo-Meter: The servo-meter is an air-actuated, positive displacement oil pump. It injects oil with each signal from the pulse counter. To actuate the servo-meter the signal received must have a pressure of at least 60 psig (4 bar). When actuated a precise amount of oil is delivered to nozzle in the outlet port of the flow valve, and is then carried by a nylon line to the air tool. A transparent sight indicator on one end of Servo-Meter gives visual verification of oil delivery.

Adjusting Knob:By means of the adjusting knob on the end of the Servo-Meter, oil delivery can be reduced in precise increments from the maximum rating down to 10% of the maximum rating (30% for 2 drop units).

Oil Reservoir: The integral oil reservoir is made of tough, transparent nylon with 10 ounces (300 ml) capacity. It has a quick fill cap and since the reservoir is not pressurized it can be filled at any time. It can also be used with a central-fill system. Gravity is recomended, however fill pressure can be up to 30 psig (2 bar).

A downstream injection lubricator can be ordered without an integral reservoir, in which case a sight dome air eliminator is available for use with a central-fill system.

Air Flow: Maximum inlet pressure of 150 psig (10 bar)and a pressure drop of 3 psi (0.2 bar):

1/2 NPTF — 4-60 scfm (2-28 dm3n/s)

3/4 NPTF — 4-90 scfm (2-43 dm3n/s)

Ambient/Media Temperature: 40° to 125°F (4° to 52°C).

Flow Valve: Zinc body.

Operating Pressure Range: 60-150 psig (4.1-10.3 bar)

Pulse Counter: Adjustable to operate the Servo-Meter on every cycle, every 5th cycle, or every 10th cycle.

Reservoir: Integral, unpressurized. 10-Ounce (300-ml)capacity transparent nylon with quick-fill cap. Optional M476R reservoir. Integral reservoir can be eliminated if a central-fill system is employed

Servo-Meter: Aluminum body; acetal end caps. 1-Drop (0.030ml)rating; optional 1/2-drop (0.015ml) or 2-drop (0.060ml)rating. Transparent sight indicator gives visual verifi cation of oil delivery.

Tubing: Optional 25 feet (8 meters) of oil-filled tubing with 420-160 check valve installed.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th