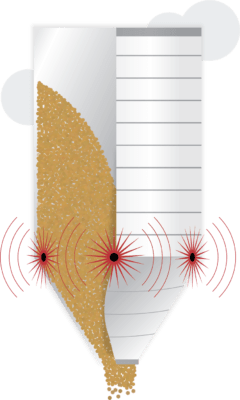

Industrial vibrators use vibration or mechanical agitation to improve material flow. It’s the same principle behind shaking a ketchup bottle: the movement breaks apart the material and loosens it from the vessel walls.

Industrial vibrators can be installed on silos, bins and hoppers to prevent bridging, arching and other material blocks.

Other uses include:

- Spreading road salt or fertilizer

- Compacting materials before shipping

- Removing dust from the production line

- Carrying out shock testing as part of quality control processes

- Sorting mixed batches of small components before they are packaged

- Settling materials and ingredients evenly by releasing air bubbles (like concrete or chocolate)

KINDS OF INDUSTRIAL VIBRATORS

- Electric vibrators are simply plugged in.

- Hydraulic vibrators use compressed fluid to generate enough mechanical energy to rotate a shaft.

- Pneumatic vibrators work the same way, but use compressed air. Sometimes, it activates an object (like a ball, roller or piston).

Industrial vibrators can also be classified according to the area of activation. For example, rotary pneumatic vibrators send out circular vibrations, while impactors are like “automatic hammers” that direct force at a specific area. These vibrators all have their pros and cons. Generally, hydraulic vibrators are used for heavy-duty jobs in wet or dusty environments. Pneumatic vibrators are used for fine powders, while electric vibrators are thought to be the quietest of the three.

INDUSTRIAL VIBRATORS: PROS AND CONS

While industrial vibrators are effective for some processes, they may not always be the best flow aid for wet or sticky materials. Just like the ketchup bottle, there will always be some residue left, no matter how much you shake it.

In some cases, industrial vibrators can also cause or worsen blocks because they end up compacting the material. Read the first-hand experience of some plant managers who installed vibrators on their vessels.

- Cement company still had to manually clean clogged shale in their silos, losing $12,000 per hour of downtime.

- A food manufacturer said that vibrators hardened the mixture. “It practically turned the flax into concrete.”

- A ready-mix plant reported that vibrators still left residue on their bins, and they still had to send a man up a ladder to poke material.

Reference: AirSweep®