Scrubgrass Generating Plant in Venango County, PA produces electricity using bituminous waste coal, a mining by-product. Advanced environmental control technologies allow the use of this coal as a clean energy source. In 2003, Scrubgrass was experiencing problems with their coal process and sought ways to correct clogging in their chutes.

THE PROBLEM

Bituminous coal contains high concentrations of sandstone, clay, and moisture. When moving the coal to a hammermill through a 20” wide, 4-ft long feed chute, the material would plug, forcing operators to shut down the process. Once the hammermill, or even the entire coal processing system was shut down, a worker would enter the chute with an airlance and chip away at the caked-on material along the chute walls. This process occurred 15 times during each 12-hour shift, took 20 minutes to complete each time, and led to increased process downtime and labor costs.

Air cannons were previously installed, and they blew hole through the material but it still accumulated around the 4” diameter hole. Three feet of surrounding material didn’t move.

THE SOLUTION

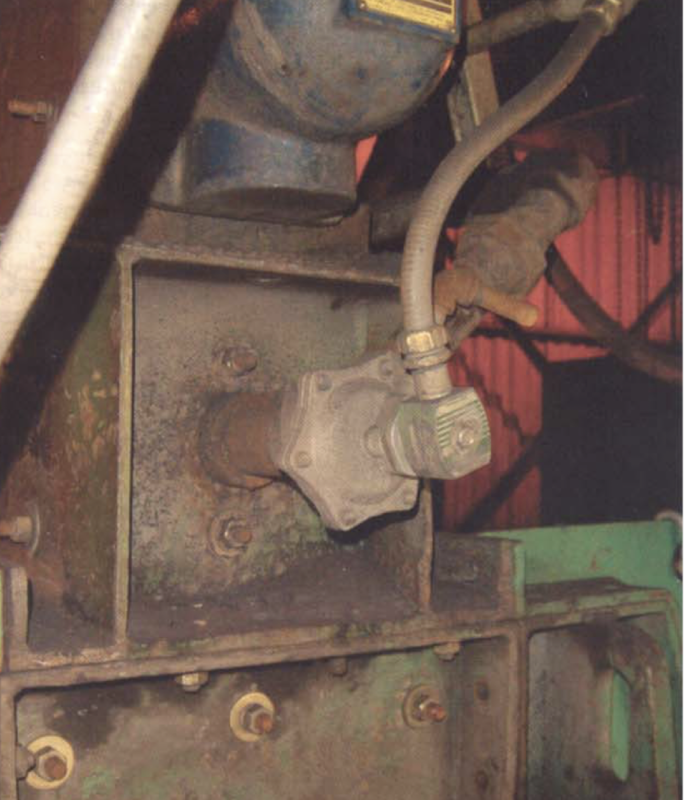

The company installed two Airweep Model VA-51 units on the feed chute leading to the hammermill. Control Concepts agreed to a return of the product if the AirSweeps did not solve the problem blockage. Using plant air, the AirSweep units were set to firea 0.25-second burst of air every 30 seconds. At approximately 2.4 cfm of air per burst, this was much less than required to operate the air cannons.

Each of the strategically positioned AirSweeps dislodged up to 8-ft diameter of material by lifting and sweeping material off walls. Mounted so the air burst diameters slightly overlapped, the loosened material would flow toward the chute’s outlet to promote material flow downward.

THE RESULTS

Monitored during the trial run, the AirSweeps operated continuously during every 12-hour shift and there were no plugging concerns on the feed chute. The AirSweeps paid for themselves within 2 weeks according to Jeffrey Campbell, Plant Engineer.

Scrubgrass purchased more units for additional feed chutes around the plant.

Reference: Airsweep

For More Information:

Tel.: 02-384-6060 | LINE: @flutech.co.th | Email: [email protected] | Facebook: @flutech.co.th | Website: https://flutech.co.th