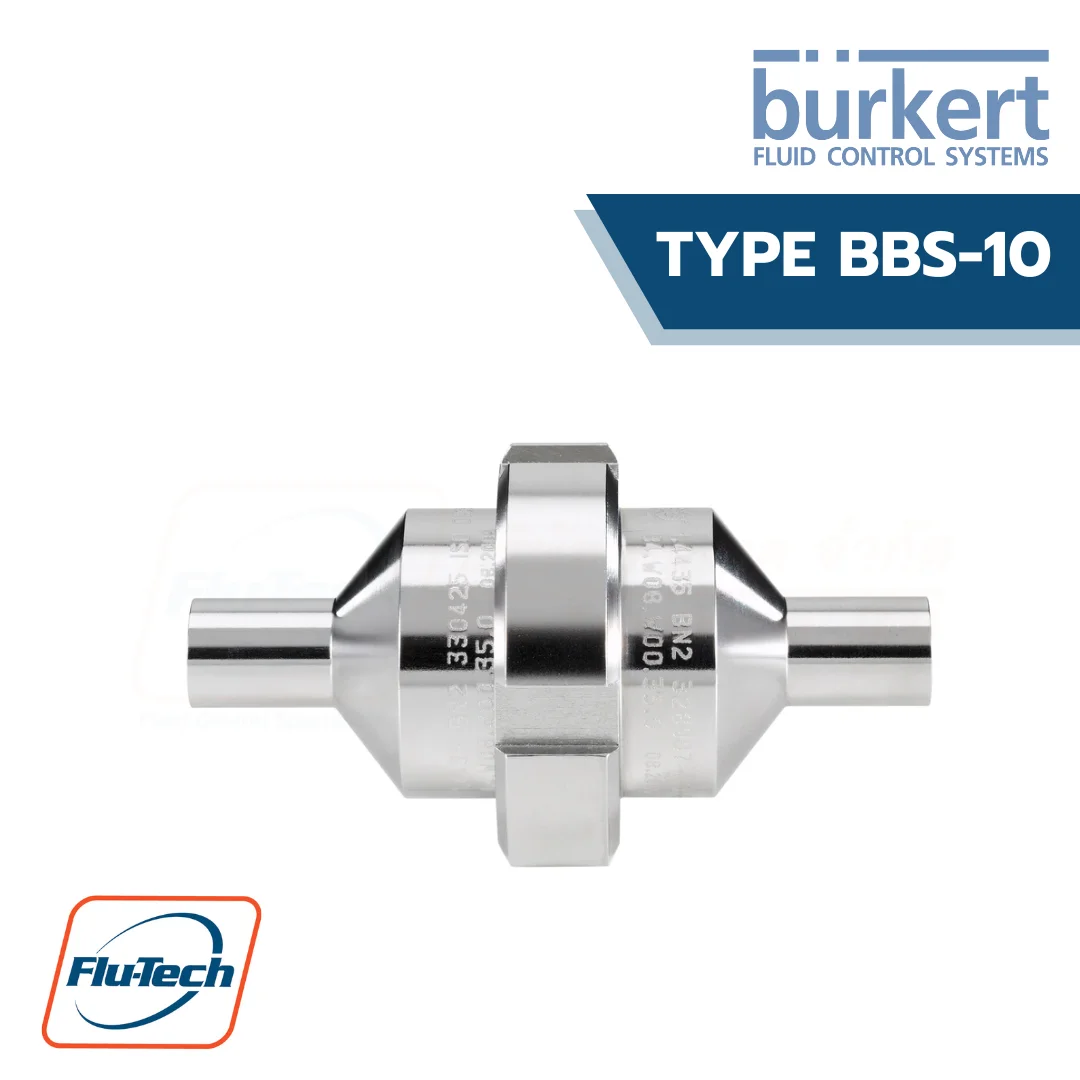

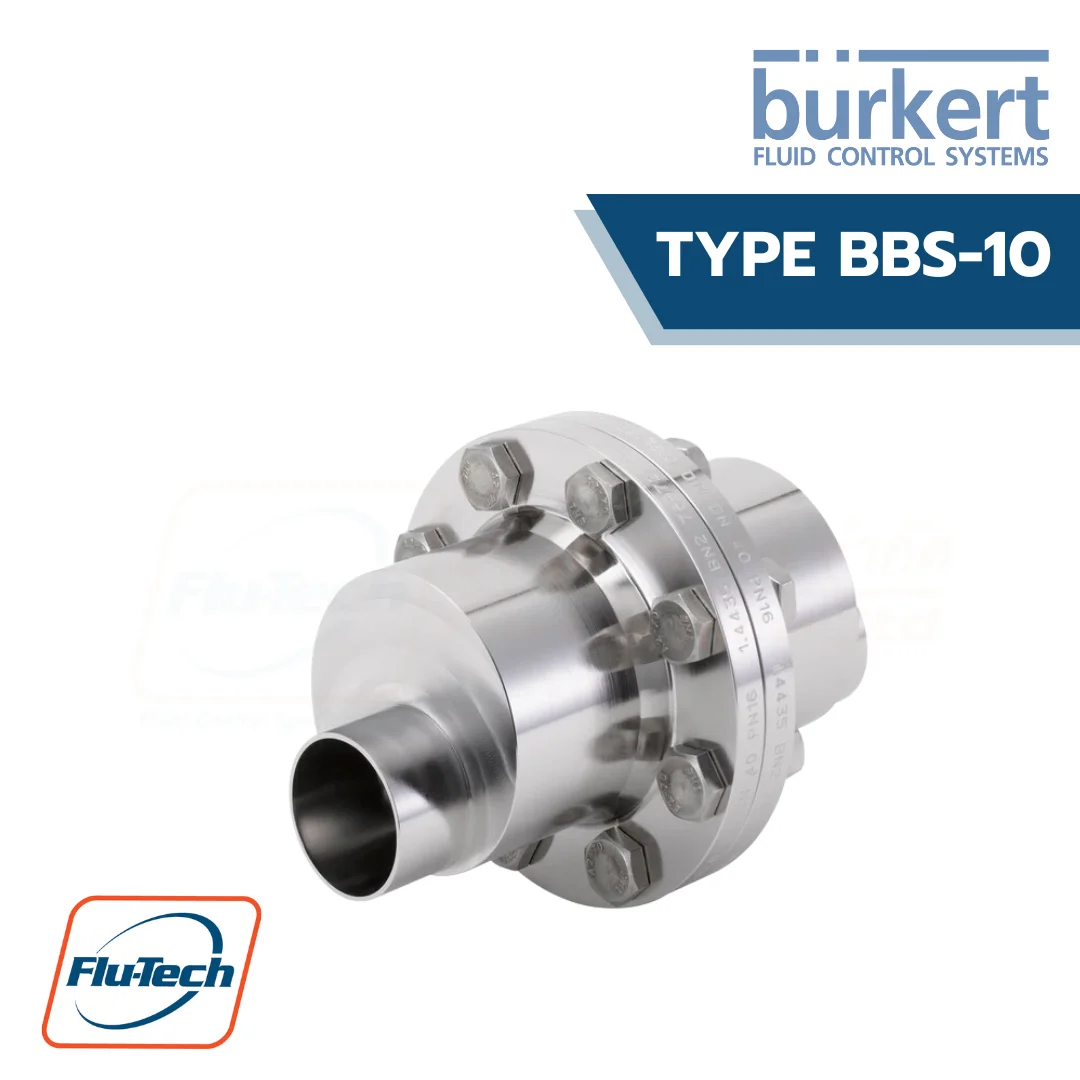

Sterile check valve

These sterile check valves are designed for fluids and steam. The design is such that the flow direction is selectable; that makes installation and simple and very cost effective. The latest standards in the biopharmaceutical markets are met. The construction provides a continuous flushing and the unique feature of the eccentric checkvalve is that it can be mounted in the vertical position and will self drain until empty providing the correct angle is achieved according to standard installation techniques. All BBS-10 check valves are suitable for a wide range of duties in many of the applications listed below.

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

General Technical Data

Technical data |

|

| Available standard sizes | ISO DN08 to DN100 BS-OD DN1/4″ to DN4″ DIN DN08 to DN100 Customized on request |

| Material medium contact | Stainless steel 1.4435 BN2 (316L) Ball cap made of PTFE Spring: 1.4401 Special materials on request |

| Material medium separated | 1.4305 or equivalent |

| Ball | 1.4435 BN2 stainless steel with PTFE-Ball |

| Seals | O-Ring, EPDM, FEP, special sealing materials on re-quest |

| Surface quality | Medium contacted surface < Ra 0.8 μm, electro polished, finer surface on request |

| Operating temperature | depending on the chosen seal material |

| Ambient temperature | – 20 to + 80 °C |

| Media | Liquids |

| Design, operating pressure | – 1 to + 16 bar (operating pressure – 1 to + 8 bar) Standard opening pressure 0.2 bar Higher or lower pressures on request |

| Applicable Standards | Pipe connection acc. to DIN 11866 ISO-Dimension Series B (ISO 4200) BS-OD-Dimension Series C (ASME BPE) DIN-Dimension Series A (DIN 11850) Conformity assessment acc. to DGRL 97-25-EG |

| Certifications | Material 3.1 FDA for all the stated seal materials USP VI for EPDM, FEP, PTFE |

*For selecting thecorrect product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th