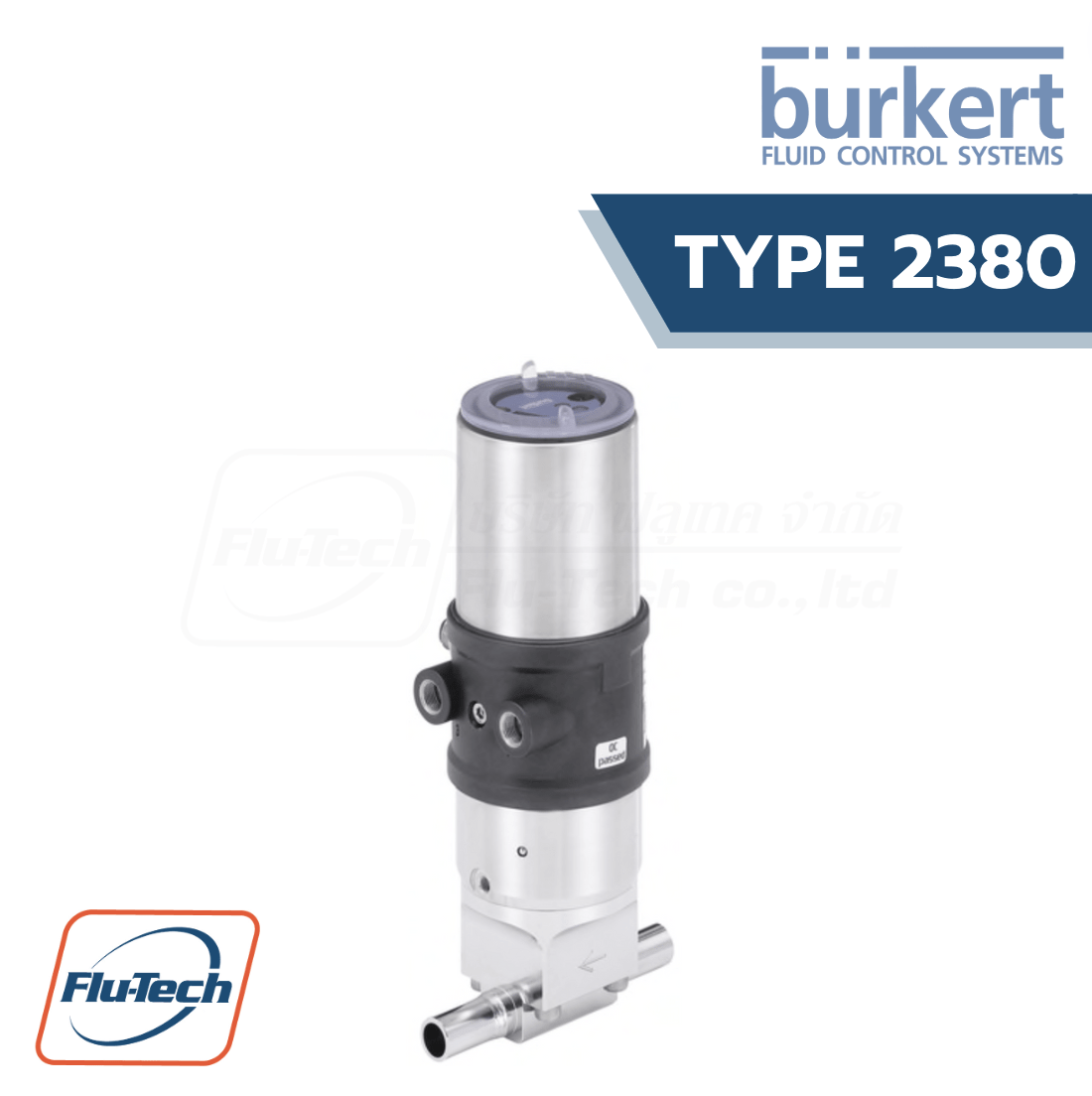

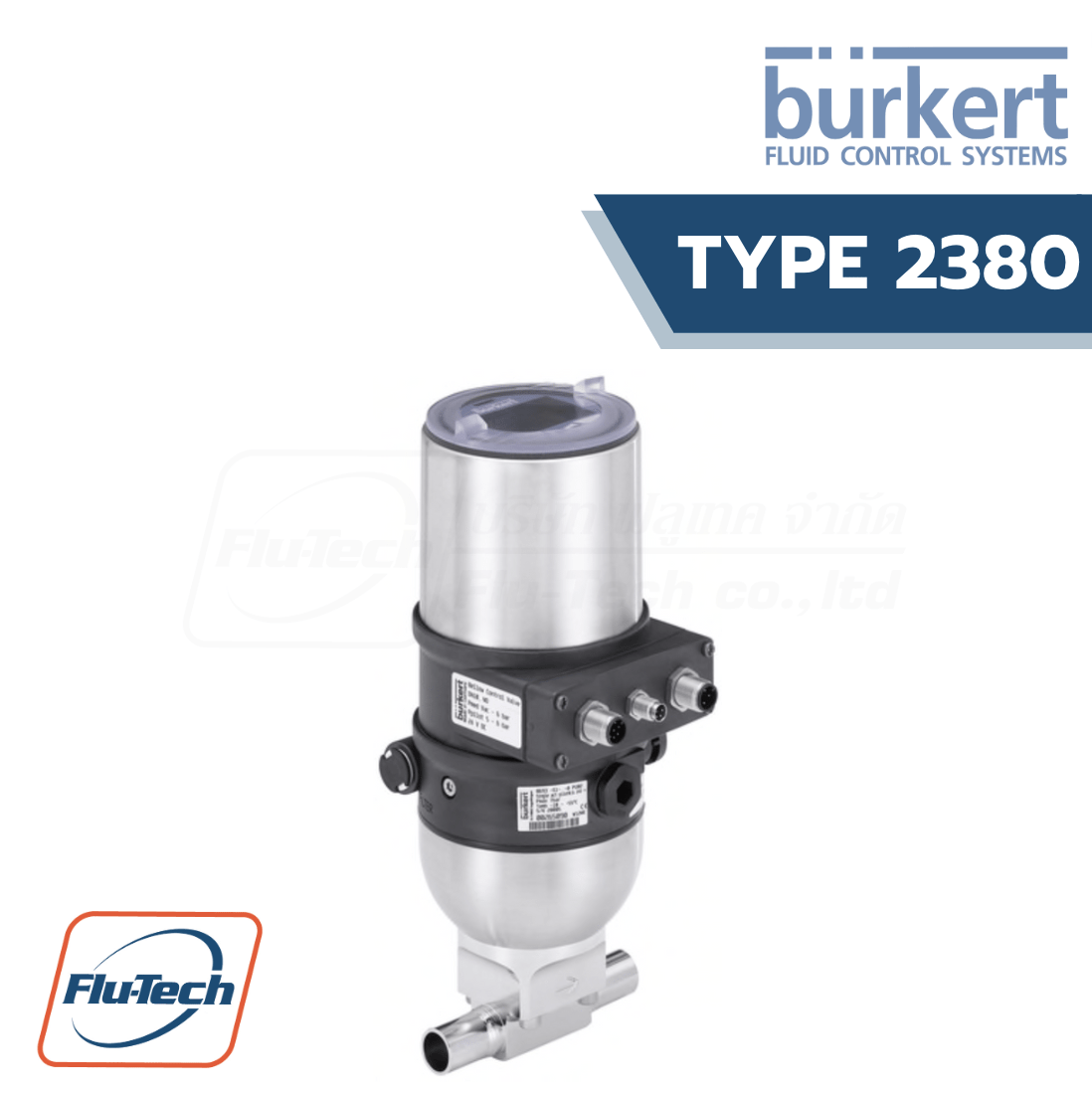

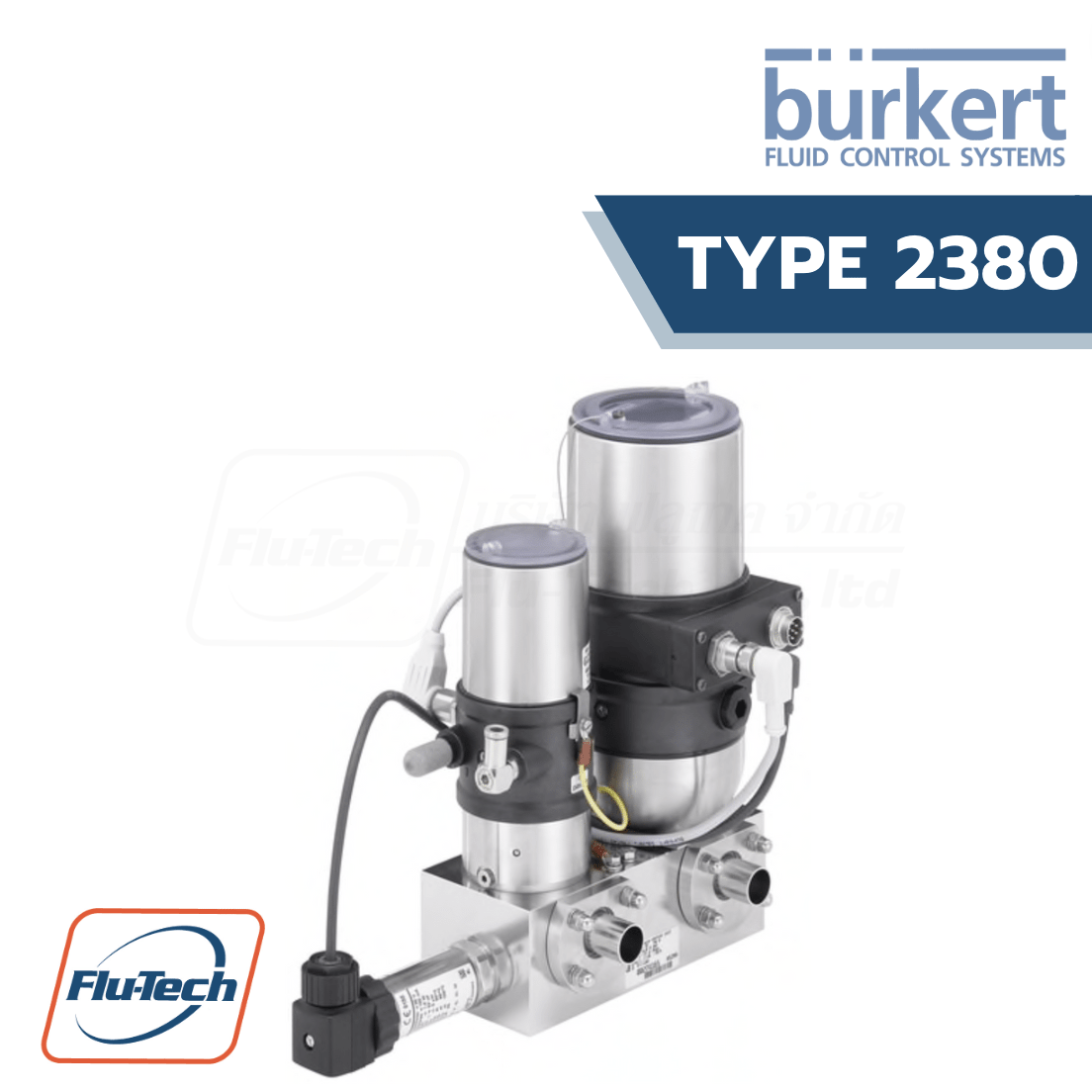

The bellow control valve is a pneumatically operated process valve with a single-acting diaphragm actuator. A PTFE bellow ensures the separation between medium and actuator. The materials used and the design of the media space allow the use under hygienic or aggressive conditions. It has a good cleanability. The combination with a controller (Type 869x) and the control cone integrated into the bellow enable the valve to handle demanding control tasks. The space-saving actuator with low internal volume not only results in a very compact size but also in remarkably low response times. The valve is characterized by a good control performance due to the low-friction design and has a linear characteristic. A certain variety of body and block system solutions are deliverable.

Downloads

Data Sheet User ManualGeneral Technical Data

Product Properties |

|

| Dimensions | Detailed information can be found in chapter “5. Dimensions” on page 6. |

|

Body material (Medium contact)

|

Stainless steel 316L ASME BPE (1.4435 BN2) |

| Bellows material (Medium contact) | Advanced PTFE |

|

Seal material (No medium contact)

|

EPDM, FKM |

| Controller material (No medium contact) | PPS, stainless steel |

| Actuator material (No medium contact) | 304 (1.4301) or CF-8 (1.4308) |

| Threaded connection standard surface quality | Ra 1.6 μm |

| Weld and clamp connections standard surface quality | Internal mechanically polished : Ra 0.6 μm Internal electrically polished : Ra 0.38 μm |

Performance Data |

|

|

KVS value

|

0.05…1.8 m3/h

|

| Seat leakage | <0.01% of full flow capacity (ANSI Class IV) |

| Pilot pressure (max.) | 5.5…7 bar(g) |

| Reaction/switching time | Typical settling time <1 sec. |

Electrical Data |

|

|

Electrical characteristics

|

Defined by the use of Type 869x |

| Electrical signal/communication | Analogue standard signal (e.g. 4…20 mA) / Bus communication (e.g. Ethernet/IP, büS) (depending on Type 869x) |

Medium Data |

|

|

Medium

|

Gases and fluids (ultra-pure, sterile, dirty, aggressive, abrasive or also highly viscous); Steam (for sterilisation).

|

|

Medium temperature

|

0…+ 80 °C (- 10 °C…+ 150 °C for restricted operating conditions)

|

| Medium pressure | Vacuum up to 6 bar (g) |

| Control medium | Air or neutral gases (DIN ISO 8573 – 1: Dust Q.-Kl. 7, Water Q.-Kl. 3, Oil Q.-Kl. X) |

Process/Port Connection & Communication |

|

|

Nominal diameter

|

DN4…DN15

|

| Nominal seat size | DN1.5…DN10 |

|

Threaded port connection

|

G (DIN EN ISO 228-1)

|

| Welded port connection |

DIN 11850 series 0 / DIN 11866 R. A / DIN 11850 R. 2 DIN 11866 R. B / DIN ISO 4200 DIN 11866 R. C / ASME BPE

|

|

Clamp connection

|

On request

|

| Pilot air ports | Thread G 1⁄8 |

| Electrical connection | Circular connectors (Multipole) / Cable gland (depending on Type 869x) |

Approvals and Certificates |

|

|

Conformity

|

CE acc. to EG declaration of conformity (2014/30/EU EMC) FDA / EG regulation no. 1935/2004

|

| Certificates |

United States Pharmacopeia (USP) Class VI – 121 °C

|

| Approvals | ATEX II Cat. 3 G/D (on request) |

Environment and Installation |

|

|

Installation position

|

See “7. Product installation” on page 8

|

| Ambient temperature |

– 10…+ 55 °C

|

| Degree of protection |

IP65/67 acc. to EN 60529

|

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th