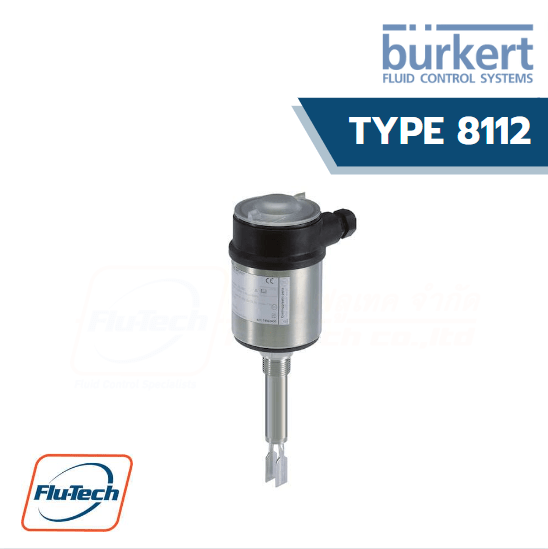

Vibrating filling level switch with extension tube

The Type 8112 is a filling level switch for liquids, using a tuning fork as the sensor element.

It is designed for industrial use in areas of process technology and can be used in liquids. Typical applications are overfill or dry run protection.

The Type 8112 is available with different sensor lengths. The immersion depth can be adapted thanks to a lock fitting.

Due to the simple and rugged measuring system, the 8112 is virtually unaf-fected by the chemical and physical features of the liquid. It works even under unfavourable conditions such as turbulence, air bubbles, foam generation (not suitable for measuring the foam thickness itself), adhesions, strong external vibrations or varying filling materials.

Downloads

Data Sheet User ManualBURKERT TYPE 8112 สามารถใช้ได้ร่วมกับ

General Technical Data

Product properties |

|

| Materials | Please make sure the device materials are compatible with the fluid you are using. Detailed information can be found in chapter “4.1. Chemical Resistance Chart – Bürkert resistApp” on page 5. Detailed information about material specifications can be found in chapter “4.2. Material specifications” on page 6 |

| Dimensions | Detailed information can be found in chapter “5. Dimensions” on page 6. |

| Probe length | 200…1000 mm (including the extension tube Ø 21.3) |

| Surface quality | Ra < 3.2 μm (thread) / Ra < 0.8 μm (clamp) |

| Measured variable | Limit level of liquids. |

| Weight | Approx. 850 g + approx. 920 g/m (extension tube) |

| Ground terminal | Stainless steel 316Ti/316L (1.4571/1.4435) |

Performance data |

|

| Dynamic viscosity η | 0.1…10000 mPa.s (requirement: with density 1) |

| Density | Selected by DIP switch: • Standard sensitivity: 0.7…2.5 g/cm3 • High sensitivity: 0.5…2.5 g/cm3 |

| Flow velocity | Max. 6 m/s (with a viscosity of 10000 mPa.s) |

| Measurement deviation | ± 1 mm |

| Repeatability | 0.1 mm |

| Hysteresis | Approx. 2 mm with vertical installation |

| Switching delay | Approx. 500 ms (On/Off) |

Electrical data |

|

| Operating voltage | Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

| Power Source (not supplied) | Limited power source according to UL/EN 60950-1 standards or limited energy circuit according to UL/EN 61010-1 §9.4 |

| Power consumption | Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

| Current consumption | Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

| Resonance frequency | Approx. 1200 Hz |

| Output | Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

Medium data |

|

| Process temperature | – 50…+ 150 °C (- 58…+ 302 °F) |

| Process pressure | – 1…64 bar/- 100…6400 kPa (- 14.51…+ 928.64 PSI) |

Process/Port connection & communication |

|

| Process connection | Thread G or NPT, ¾” or 1″; clamp 2″ |

| Electrical connection | Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

Approvals and Certificates |

|

| Standards Degree of protection according to IEC/EN 60529 |

IP66/IP67 with M20 × 1.5 gland mounted and tightened |

| Overvoltage category according to IEC 61010-1 | Category III |

| Protection class according to IEC 61010-1 |

Depending on the device version Detailed information can be found in chapter “2. Product versions” on page 4. |

| Directives | |

| CE directives | The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination Certificate and/or the EU Declaration of conformity (if applicable). |

| NAMUR recommendations | IEC 60947-5- 6 (EN 50227) |

| Approvals | |

| ATEX/IECEx | EN50014, EN50020, EN50284 Detailed information can be found in chapter “3.1. Certification ATEX” on page 5. |

Environment and installation |

|

| Ambient temperature | • Operating on the housing: – 40…+ 70 °C (- 40…+ 158 °F) • Storage and transport: – 40…+ 80 °C (- 40…+ 176 °F) |

| Temperature derating | Detailed information can be found in chapter “6.1. Temperature derating diagram” on page 8. |

| Relative air humidity | 20…85 %, without condensation |

*For selecting thecorrect product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th