DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

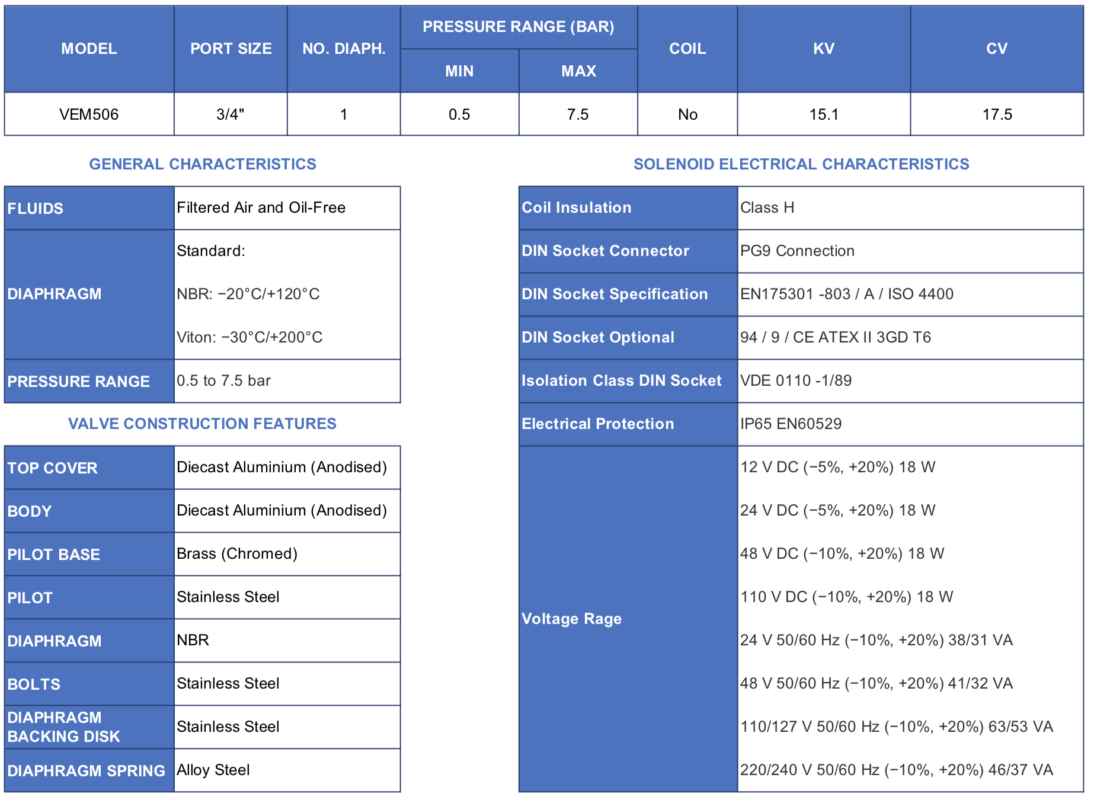

MODEL | PORT SIZE | NO. DIAPH. | PRESSURE RANGE (BAR) | COIL | KV | CV | |

MIN. | MAX. | ||||||

VNP506 | ¾” | 1 | 0.5 | 7.5 | Yes | 15.1 | 17.5 |

VNP508 | 1” | 1 | 0.5 | 7.5 | Yes | 26.3 | 30.6 |

VEM506 | ¾” | 1 | 0.5 | 7.5 | No | 15.1 | 17.5 |

VEM508 | 1” | 1 | 0.5 | 7.5 | No | 26.3 | 30.6 |

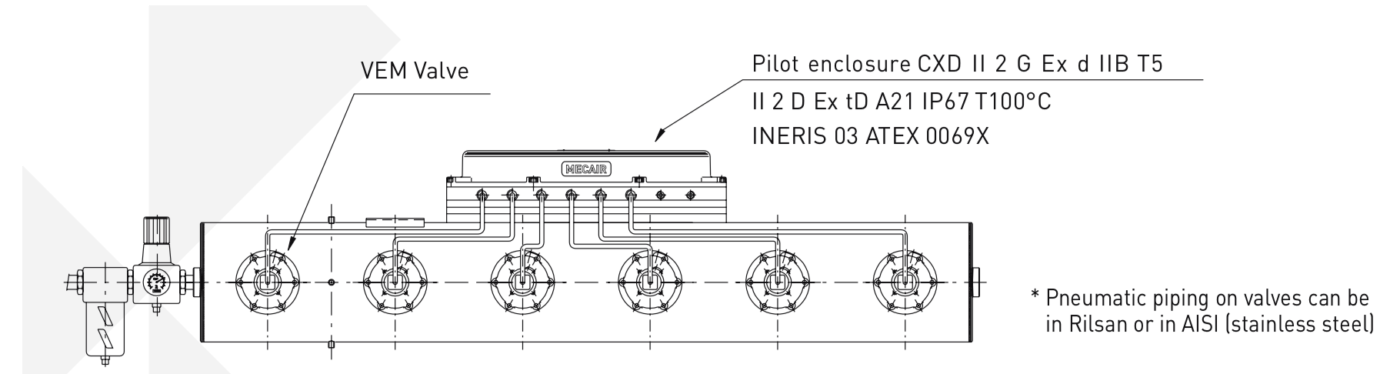

FULL IMMERSION

The patented Mecair “Full Immersion” System consists of a round header tank with fully integrated diaphragm valves, suitable for dust collector filter applications, in particular for reverse pulse-jet filter cleaning of filter bags, cartridges, envelope filters, ceramic filters and sintered metal fibre filters. The MECAIR – VEM506 diaphragm valve has been specifically designed to be mounted onto a round header tank. This valve is exclusively a Mecair design and has a worldwide patent.

FULL IMMERSION STAINLESS STEEL

The MECAIR – VEM506 diaphragm valve is manufactured from diecast aluminium and is anodised. The valves are mounted on a painted carbon steel, stainless steel or aluminium tank.

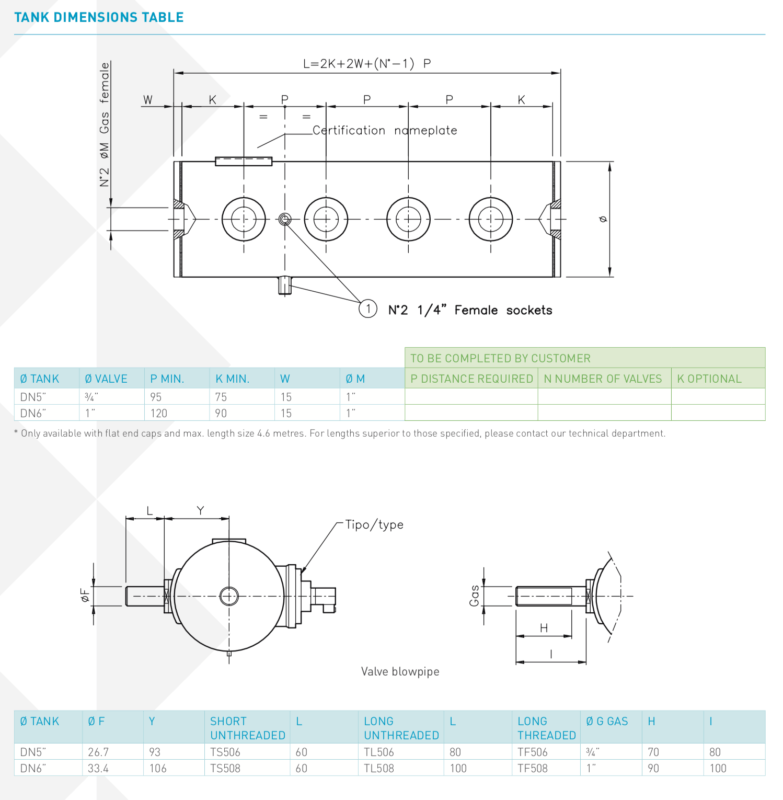

TANK PREPARATION SPECIFICATION

• Abrasive cleaning and degreasing

• Immersed in acid bath to remove any and all unnatural properties (pickling)

STANDARD CARBON STEEL PAINT SPECIFICATION

- Abrasive cleaning, degreasing and paint preparation

- Undercoat RAL 7042: 25 microns

- Final colour RAL 5012: 25 microns

- Total thickness 50 microns (−10%/+40%)

OPERATING RECOMMENDATIONS

Ensure air supply is clean and dry. (We recommend the installation of compressed- air filter units to be installed directly before the pressure vessel, in order to ensure clean and dry air is supplied to the diaphragm valve). Operating pressure min./ max. 0.5–7.5 bar.a) AIR INLET PIPE TO HEADER TANK/ PRESSURE VESSEL: Minimum ø 1” for tanks with a 1” valve or 11⁄2” valves. We always recommend the air inlet pipe to tank to be the same size as the diameter of valve being used, or the next available size down. This ensures that the air supply to the tank is sufficient to allow the tank to refill in as short a time as possible. With the correct volume of air in the tank, this ensures the correct and efficient functioning of the diaphragm valve without any waste of compressed air.

b) ORIENTATION: Can work in all orientations.

c) ELECTRICAL ON TIMES AND PULSE TIMES: For the correct and efficient use of a diaphragm valve, it is important to set the correct pulse times and pause times. Average pulse times range from 100 ms– 250 ms depending on size of the valves being used. Pause times also depend on number of valves in the filter, but MECAIR recommends a total cycle time of between 300 and 360 seconds for the total number of valves installed.

b) ORIENTATION: Can work in all orientations.

c) ELECTRICAL ON TIMES AND PULSE TIMES: For the correct and efficient use of a diaphragm valve, it is important to set the correct pulse times and pause times. Average pulse times range from 100 ms– 250 ms depending on size of the valves being used. Pause times also depend on number of valves in the filter, but MECAIR recommends a total cycle time of between 300 and 360 seconds for the total number of valves installed.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th