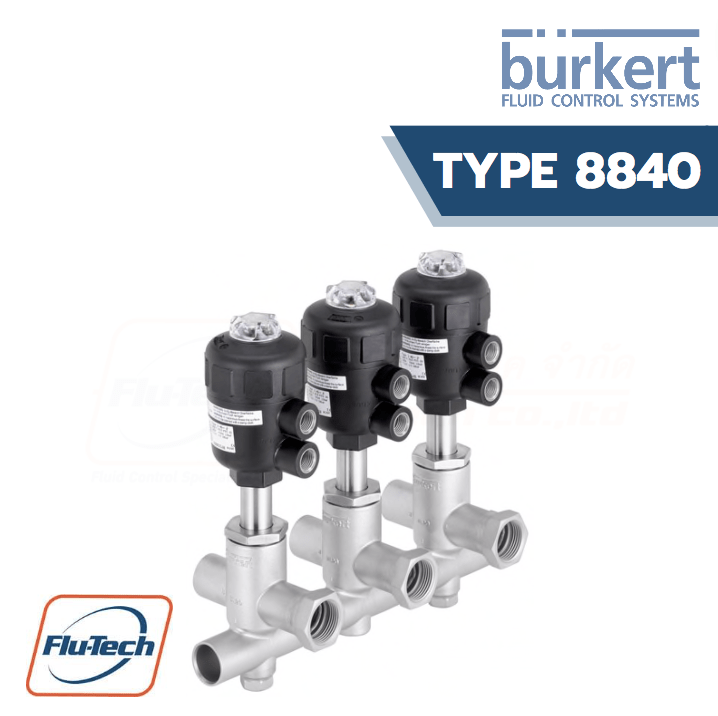

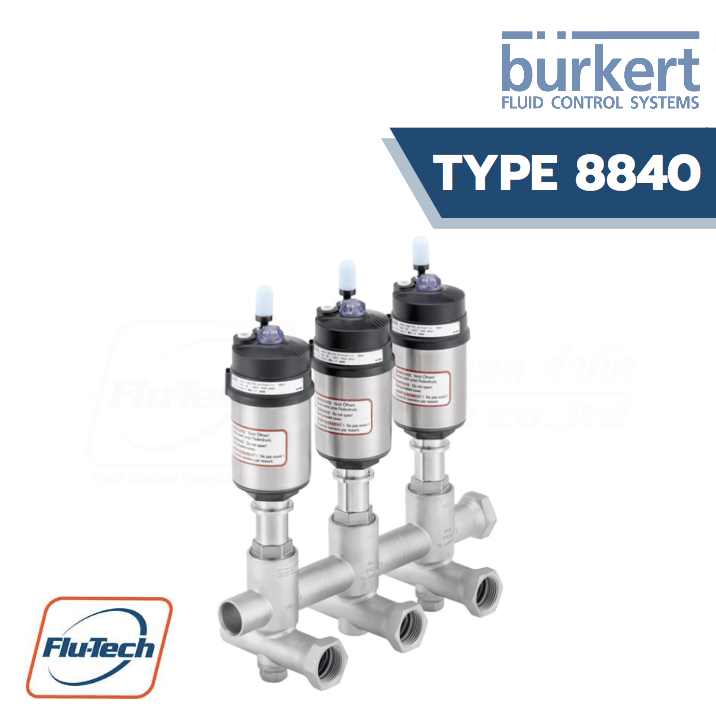

Modular process valve cluster – distribution and collecting

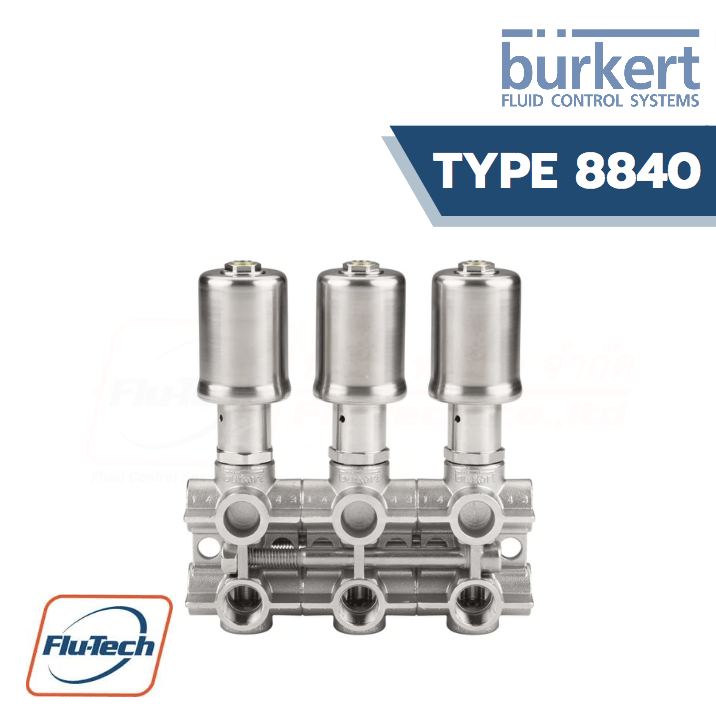

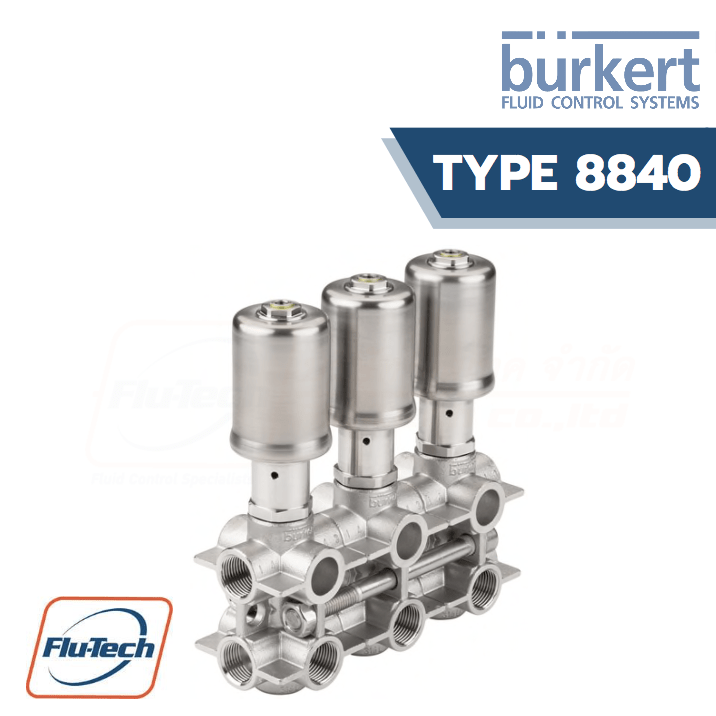

Type 8840 comes with ready to install modules of tried and tested Bürkert process valves. The valve cluster, based on a modular valve body, allows different configurations. The individual parts are joined hermetically tight and in a very compact way. No installation effort for pipework, fittings or sealings is needed.

For the sizes DN20 (¾”) and DN25 (1″) orbital welding is used. The smaller variants in DN10 are threaded together using trusted graphite seals. To avoid dangerous water hammer, all valves have the flow direction below the seat. This is made possible by the two variants for the fluidic main function distribution and collecting, mixing or feed.

Depending on the requirement and preferred type of automation, it is possible to choose from different actuator variants. The robust CLASSIC actuators (in stainless steel or plastic) are controlled by a central valve island or by a pilot valve. The proven ELEMENT actuators allow a simple decentralized automation by using intelligent control heads Furthermore it is possible to expand the system by using continuous control valves, sensors, customer specific pipework or further accessories.

Downloads

Data Sheet User ManualBURKERT TYPE 8840 สามารถใช้ได้ร่วมกับ

General Technical Data

Modular Process Valve Cluster Type 8840 |

|

Product Properties |

|

| Dimensions | Detailed information can be found in the data sheet. |

Material |

|

| Body |

Cast stainless steel 316L (CF3M)

|

| Seal | PTFE |

| Spindle Packing |

PTFE seal with spring compensation

|

| INOX DN10 Actuator |

Stainless steel (on request)

|

| CLASSIC DN20, DN25 Actuator | PA (PPS on request) |

| ELEMENT DN20, DN25 Actuator | Actuator PPS, stainless steel cover 1.4561 (316Ti) |

| Nominal Diameter | DN10 – threaded DN20, DN25 – welded |

| Control Function | CFA (closed by spring force) CFB (opened by spring force) on request |

|

Number of Valve Positions for DN10 (threaded)

|

2…9 (clusters with larger number of valves on request )

|

| Number of Valve Positions for DN20, DN25 (welded) | 2…5 (clusters with larger number of valves on request ) |

Performance Data |

|

|

Nominal Pressure

|

PN25 (housing)

|

| Pilot Pressure | Max. 10 bar |

Medium Data |

|

|

Medium

|

Water, alcohols, oils, fuels, hydraulic fluid, saline solutions, alkalis, organic solvents, vapour

|

|

Medium temperature

|

– 10…+ 180 °C |

| Viscosity | Max. 600 mm2/s |

| Control medium | Neutral gases, air |

Process/Port Connection & Communication |

|

|

Threaded Port Connection

|

G 3⁄8…G 1, NPT 3⁄8…NPT 1

|

| Welded Port Connection | ISO 4200 (on request) |

| Clamp Port Connection | DIN 32676/series B (on request) |

|

INOX DN10 Pilot Air Ports

|

Female elbow fitting (hose Ø4)

|

| CLASSIC DN20, DN25 Pilot Air Ports | G1⁄4 |

| ELEMENT DN20, DN25 Pilot Air Ports | Push-In 6/4 |

Approvals and Certificates |

|

|

Conformity

|

FDA EC Regulation 1935/2004SIL |

|

Approvals (on request)

|

Explosion proof ATEX

|

Environment and Installation |

|

| INOX DN10 Ambient Temperature |

0…+ 60 °C

|

|

CLASSIC DN20, DN25 Ambient Temperature

|

– 10…+ 60 °C (PA actuator) |

|

ELEMENT DN20, DN25 Ambient Temperature

|

0…+ 60 °C

|

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th