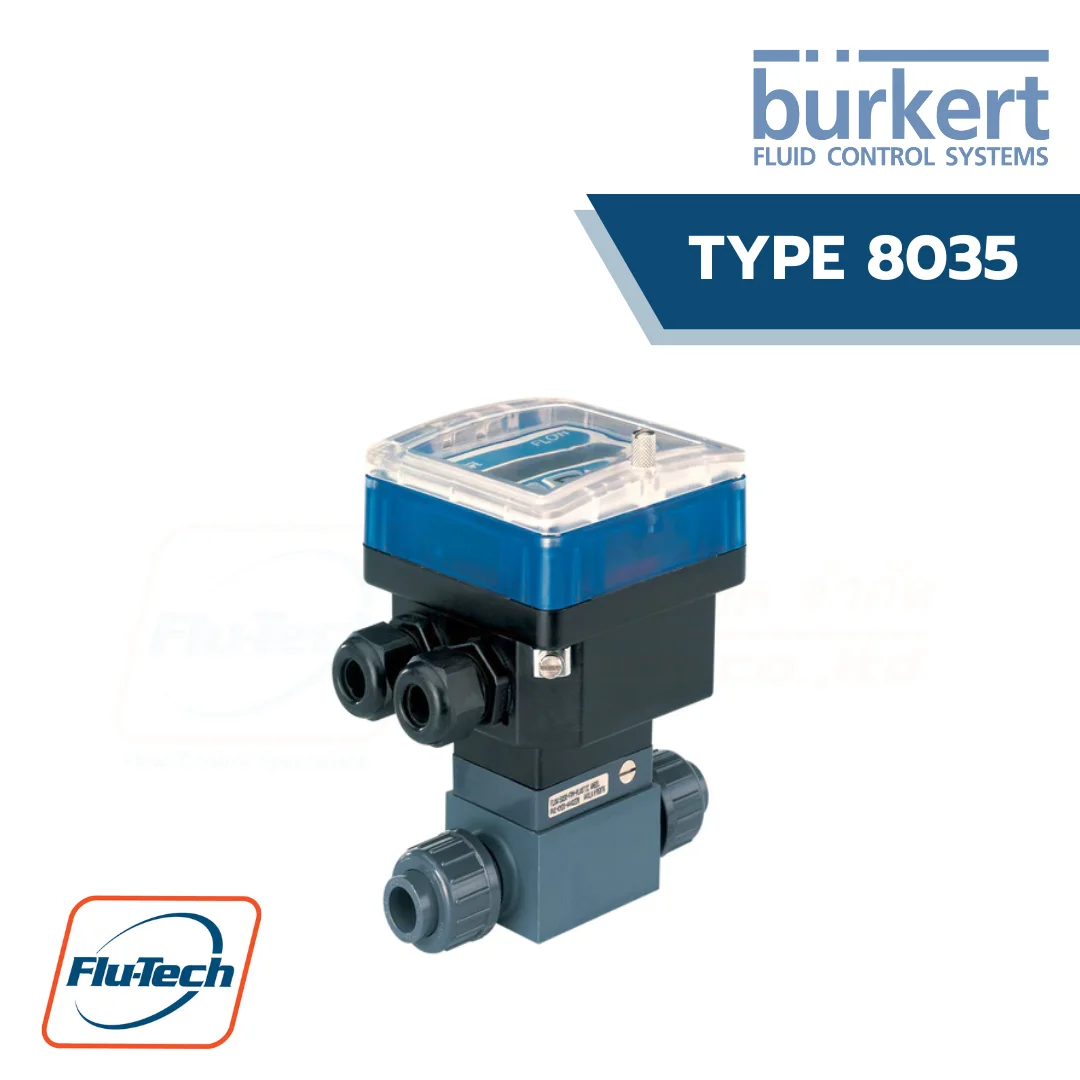

Inline flowmeter or batch controller with paddle wheel

The Type 8035 flowmeter or batch controller is specially designed for use in neutral, slightly aggressive, solid free liquids. The flowmeter or batch controller is made up of a compact sensor-fitting with paddle wheel (S030) and a transmitter (SE35) which are quickly and easily connected together by a bayonet fitting. The Bürkert designed sensor-fitting system ensures simple installation of the devices into all pipelines from DN06…DN65. The flowmeter with paddle wheel sensor is available in two versions:

- standard signal output version or

- battery powered indicator/totalizer version without output.

Downloads

Data Sheet User ManualTYPE 8035 สามารถใช้ได้ร่วมกับ

General Technical Data

Product properties |

|

| Non wetted parts | |

| Housing, cover | PC |

| Lid | PC |

| Front panel foil | Polyester |

| Screws | Stainless steel |

| Cable glands | PA |

| Sensor-fitting body, sensor armature | Brass, stainless steel, PVC, PP or PVDF (depending on S030 version) |

| Seal | FKM or EPDM (depending on S030 version) |

| Axis and bearings | Ceramics (Al2O3) |

| Paddle wheel | PVDF |

| Dimensions | Detailed information can be found in chapter “5. Dimensions” on page 12. |

| Measuring element | Paddle wheel |

| Display | 15 × 60 mm, 8-digit LCD, alphanumeric,15 segments, 9 mm high |

| Compatibility | Any pipe from DN 06…DN 65 which is fitted with Bürkert S030 Inline sensor-fitting. For the selection of the nominal diameter of the Inline sensor-fittings, see data sheet Type S030. |

| Pipe diameter | DN 06…DN 65 |

| Measuring range | • Flow rate: 0.5…1000 l/min (0.13…265 gpm) • Flow velocity: 0.3…10 m/s |

Performance data |

|

| Measurement deviation | • Teach-In: ± 1 % of the measured value1.) at Teach-In flow rate value • Standard K-factor: ± 2.5 % of the measured value1.) |

| Repeatability | ± 0.4 % of the measured value1.) |

| Linearity | ± 0.5 % of full scale1.) |

Electrical data |

|

| Power source (not supplied) | Limited power source according to UL/EN 60950-1 standards or limited energy circuit according to UL/EN 61010-1 §9.4 |

| DC reverse polarity protection | Yes |

| Over-voltage protection | Yes |

| Voltage supply cable | • Cable with maximum operating temperature greater than 80 °C (176 °F) (90 °C (194 °F) for UL-Recognized version) • Shielded • Max. 50 m length |

Medium data |

|

| Fluid temperature | With sensor-fitting Type S030 in: • PVC: 0…+ 50 °C (+ 32…+ 122 °F) • PP: 0…+ 80 °C (+ 32…+ 176 °F) • PVDF, stainless steel or brass: – 15…+ 100 °C (+ 5…+ 212 °F) See data sheet Type S030 for more information. |

| Fluid pressure | • PN 10 with plastic sensor-fitting • PN 16 (PN 40 on request) with metal sensor-fitting Detailed information can be found in the data sheet of the Inline sensor-fittings, see data sheet Type S030 for more information. |

| Viscosity | Max. 300 cSt |

| Rate of solid particles | Max. 1 % . |

| Maximum particle size | 0.5 mm |

Process/Port connection & communication |

|

| Port connection | • Metal: Internal or external thread, weld ends, clamp or flange • Plastic: true union with nut and solvent/fusion socket, spigot or external thread See data sheet Type S030 for more information. |

| Approvals and certificates | |

| Standards Degree of protection2.) accord-ing to IEC/EN 60529 |

IP65 under the following conditions: device wired, cover and lid screwed tight and cable plug or glands mounted and tightened or with blind plug if not used |

| CE directives | The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination Certificate and/or the EU Declaration of conformity (if applicable). |

| Pressure Equipment Directive | Complying with Article 4, Paragraph 1 of 2014/68/EU directive Detailed information on the pressure equipment directive can be found in chapter “3.2. Pressure Equipment Directive” on page 9. |

| Certification | UL-Recognized for US and Canada |

Environment and installation |

|

| Relative air humidity | ≤ 80 %, without condensation |

| Height above sea level | Max.2000 m |

| Operating condition | Continuous |

| Equipment mobility | Fixed |

| Application range | Indoorandoutdoor(protectthedeviceagainstelectromagneticinterference,ultravioletrays andagainsttheeffectsofclimaticconditions) |

| Installation category | Category II according to UL/EN 61010-1 |

| Pollution degree | Degree 2 according to UL/EN 61010-1 |

*For selecting thecorrect product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th