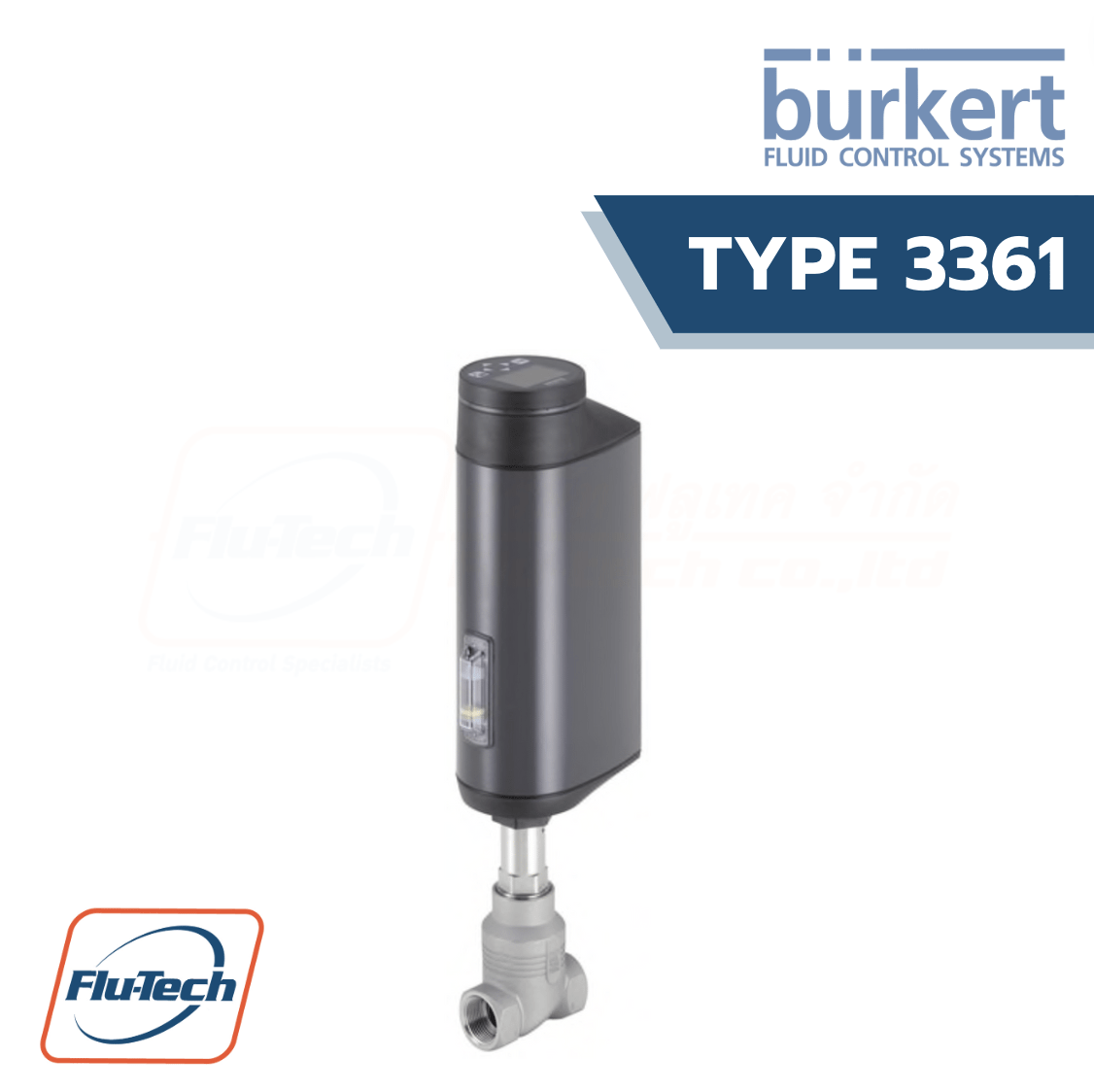

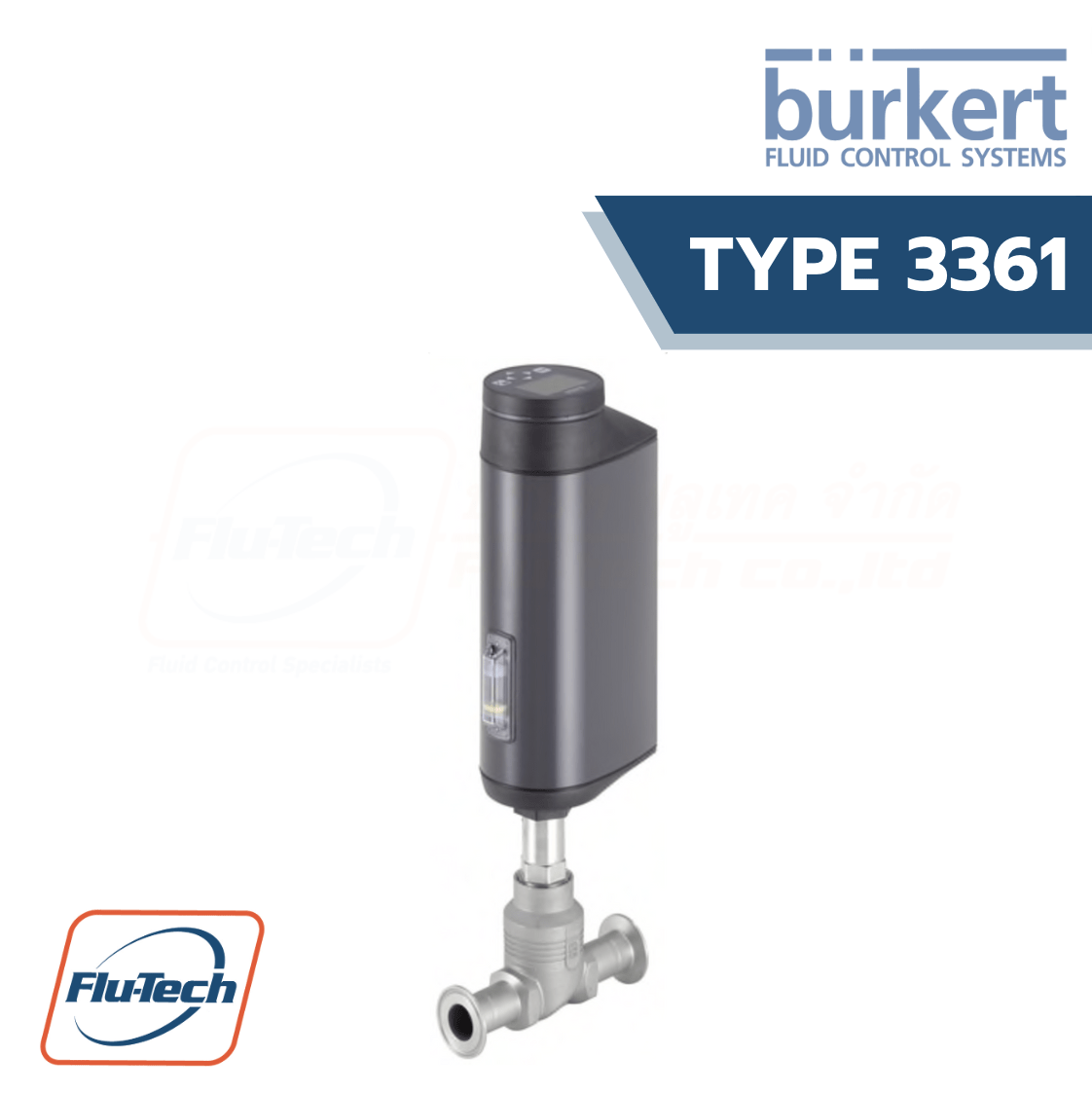

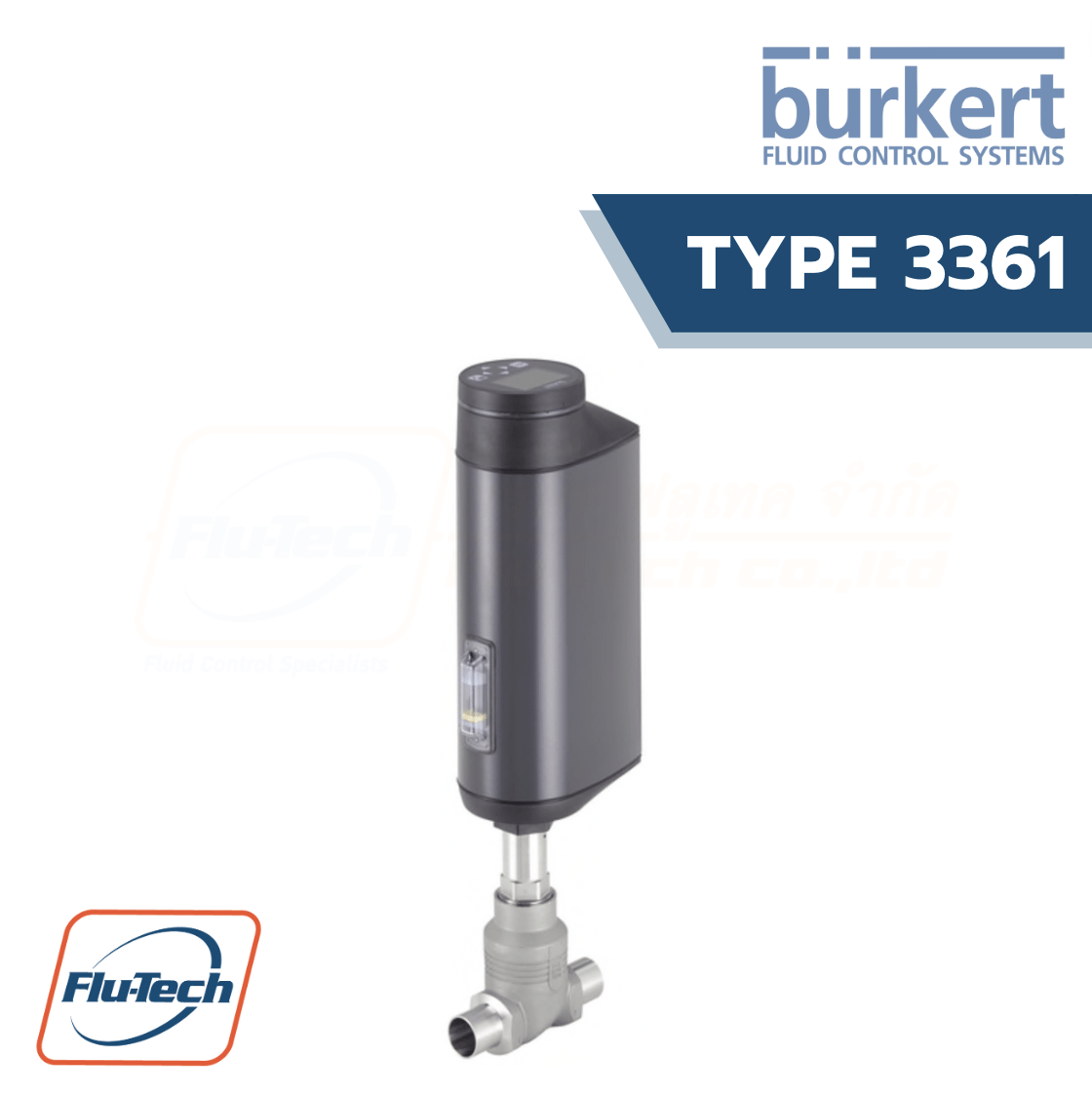

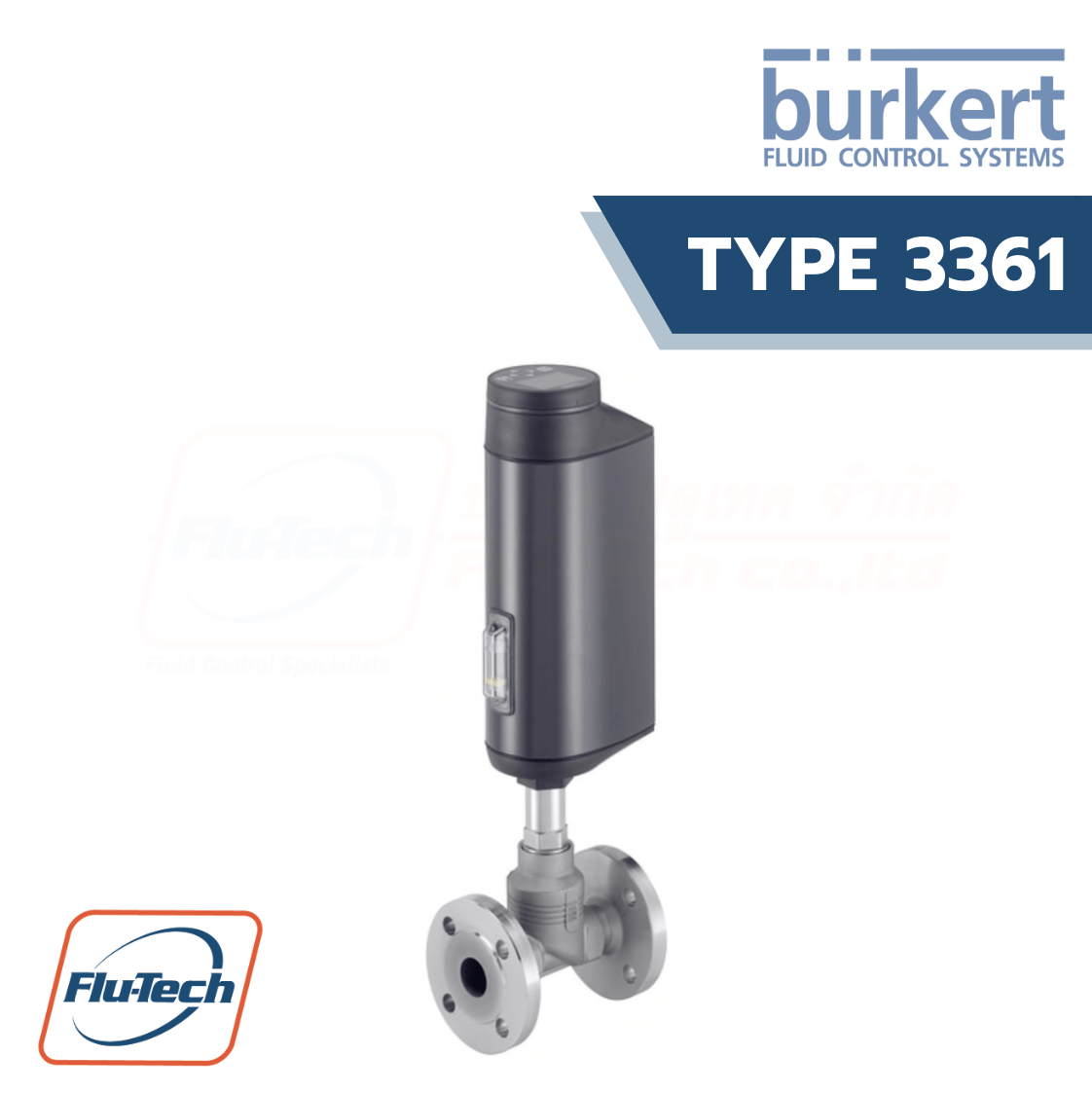

Electromotive 2 way globe control valve

The innovative process controller Bürkert valve Type 3361 is the solution when it comes to demanding control tasks and operating conditions.

The electromotive actuator with ball screw positions the control cone with highest precision. A unique feature is its high positioning speed of 6 mm/s, that reacts quasi delay-free to process signals, and can be varied according to customer demands. Pressure variations or shocks in the medium aren´t transferred to the valve position. Each flow optimized valve housing can be equipped with up to 5 different valve seats for a precise adaptation according to customer needs. If necessary, the safety position can be approached by an optional energy storage in case of power failure.

Downloads

Data Sheet User ManualBURKERT TYPE 3361 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

|

Dimensions

|

Detailed information can be found in chapter “4. Dimensions” on page 8.

|

| Material | Detailed information can be found in chapter “3. Materials” on page 6. |

| Design |

Globe control valve

|

| Nominal diameter | DN10…50, NPS 3⁄8…2 |

| Safety setting in case of power failure | With SAFEPOS energy-pack: open, closed or freely programmable / Without SAFEPOS energy-pack: blocked in last position |

| Flow direction |

Against closing direction (below seat)

|

| Controller version | Position controller or process controller |

| Weight |

4 kg (only actuator, total weight depends on the port connection)

|

Performance Data |

|

|

Operating pressure

|

0…25 bar(g) (see “5.1. Fluidic data” on page 14) Vacuum version up to – 0.9 bar(g) (optional) |

| Nominal pressure |

PN25 (DIN EN 1333), Class 150 (DIN EN 1759)

|

| KVS value | 0.1…37 m3/h (see “5.1. Fluidic data” on page 14) |

| Flow characteristic | Linear or equal percentage (see “5.1. Fluidic data” on page 14) |

| Seat leakage (DIN EN 60534 – 4) | Class III, IV and VI (see “5.1. Fluidic data” on page 14) |

| Closing time | 3.3…6.2 s (depending on travel speed and stroke) |

| Theoretical rangeability | Up to 50:1 (see “5.1. Fluidic data” on page 14) |

| Travel speed | 6 mm/s (for actuator force 1300 N) 4 mm/s (for actuator force 2500 N) |

|

Dead band of the position control

|

±0.1% |

Electrical Data |

|

|

Operating voltage

|

24 V DC ±10% (max. residual ripple 10%)

|

| Operating current | Max. 3 A (at max. load and including 1 A charging current of the optional SAFEPOS energy-pack) / At minimum operating temperature additionally 2 A |

| Protection class (DIN EN 61140) | 3 |

| Duty cycle | 100% |

| Standby consumption | 2…5 W |

| Standard signal (analogue) | Setpoint: 0/4…20 mA, 0…5/10 V and binary input (further inputs and outputs optional, see “5.3. Electrical control and interfaces” on page 19) |

| Fieldbus (digital) | Bürkert system bus (büS) (Standard) / CANopen (optional) /EtherNet/IP, PROFINET, Modbus/TCP (optional via integrated gateway) |

Media Data |

|

|

Process medium

|

Steam, neutral gases, water, alcohols, oils, fuels, hydraulic fluids, salt solutions, lyes, organic solvents, oxygen (optional) |

|

Medium temperature

|

– 40…+ 230 °C (see “5.2. Operating limits” on page 16)

|

| Viscosity |

Up to 600 mm2/s

|

Process/Port Connection & Communication |

|

|

Welded port connection

|

DIN EN ISO 1127/ISO 4200/DIN11866 B DIN 11850 2/DIN 11866 A ASME BPE/DIN 11866 C SMS 3008 |

| Clamp port connection | DIN 32676 B (pipe ISO 4200) DIN 32676 A (pipe DIN 11850 2) ASME BPE |

| Threaded port connection | G (EN ISO 228-1) Rc (EN ISO 228-1, ISO 7/1 /DIN EN 10226-2) NPT (ASME B 1.20.1) |

| Flange port connection | DIN EN 1092-1 ANSI B 16.5 JIS 10K |

|

Actuator electrical connection

|

Terminal strip with cable gland, 3 x M20 or 2 M12 circular plugs, 5 pin and 8 pin, 1 M12 circular socket, 5 pin (only for process controller function) |

| Fieldbus gateway electrical connection |

2 M12 circular sockets, 4 pin (only for industrial ethernets)

|

Approvals and Certificates |

|

|

Conformity

|

Food EGV 1935/2004 FDA (Optional) |

| Approval | Explosion protection ATEX/IECEx (Optional) (see “2. Approvals” on page 5) cULus (Optional) (see “2. Approvals” on page 5) |

| Ignition protection class | II 3G Ex ec IIC T4 Gc II 3D Ex tc IIIC T135 °C Dc |

Environment and Installation |

|

|

Ambient temperature

|

– 25…+ 65 °C (only without additional modules) (Derating see “Operating limits for ambient and medium temperature” on page 17) |

| Degree of protection |

IP65/IP67 (DIN EN 60529), NEMA 4X

|

| Vibration, sinusoidal resistance |

5 g (IEC 60068-2-6 Test Fc)

|

| Shock, mechanical resistance | 50 g (IEC 60068-2-27 Test Ea) |

| Installation position |

Any, preferably actuator face up

|

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th