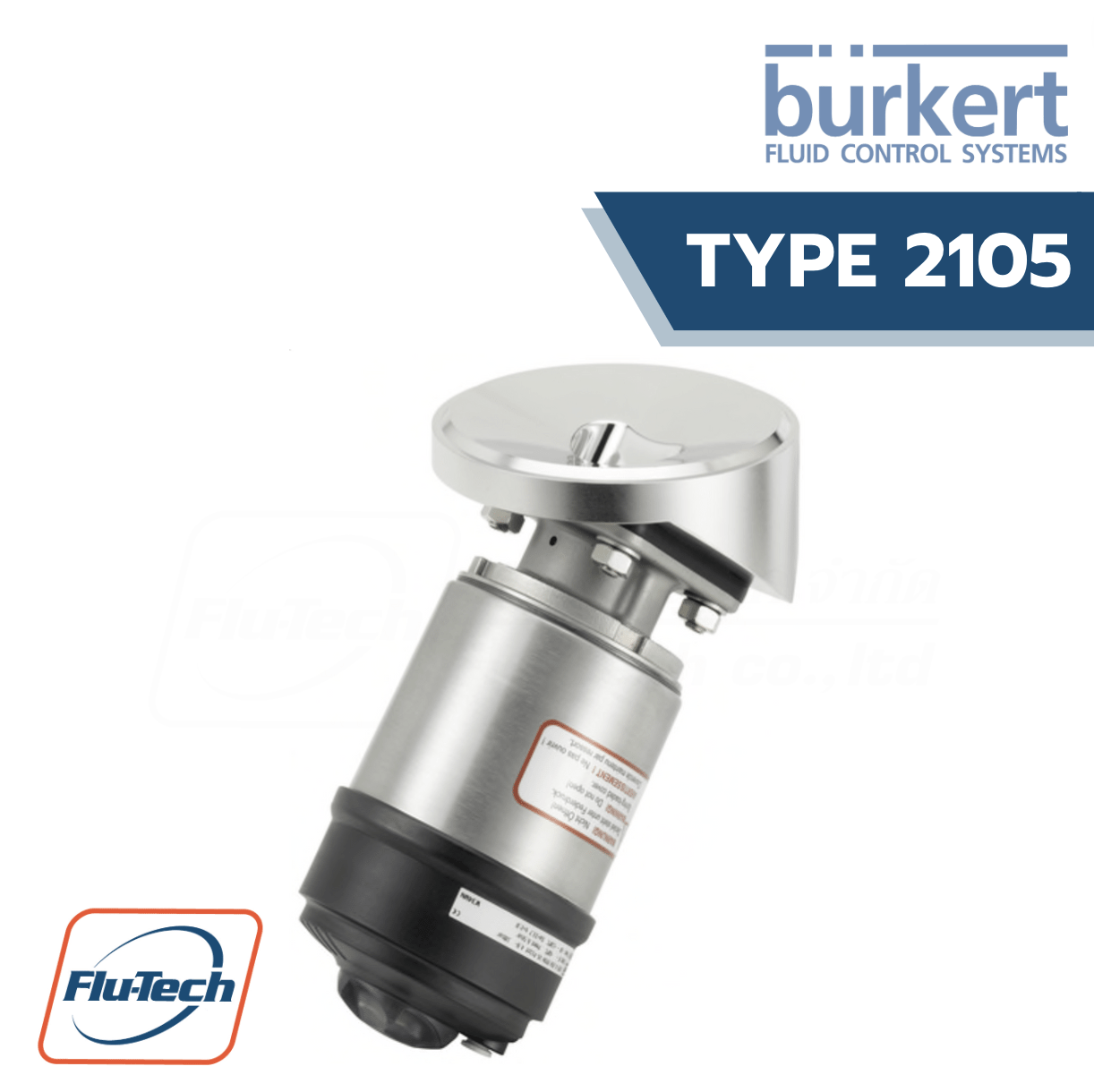

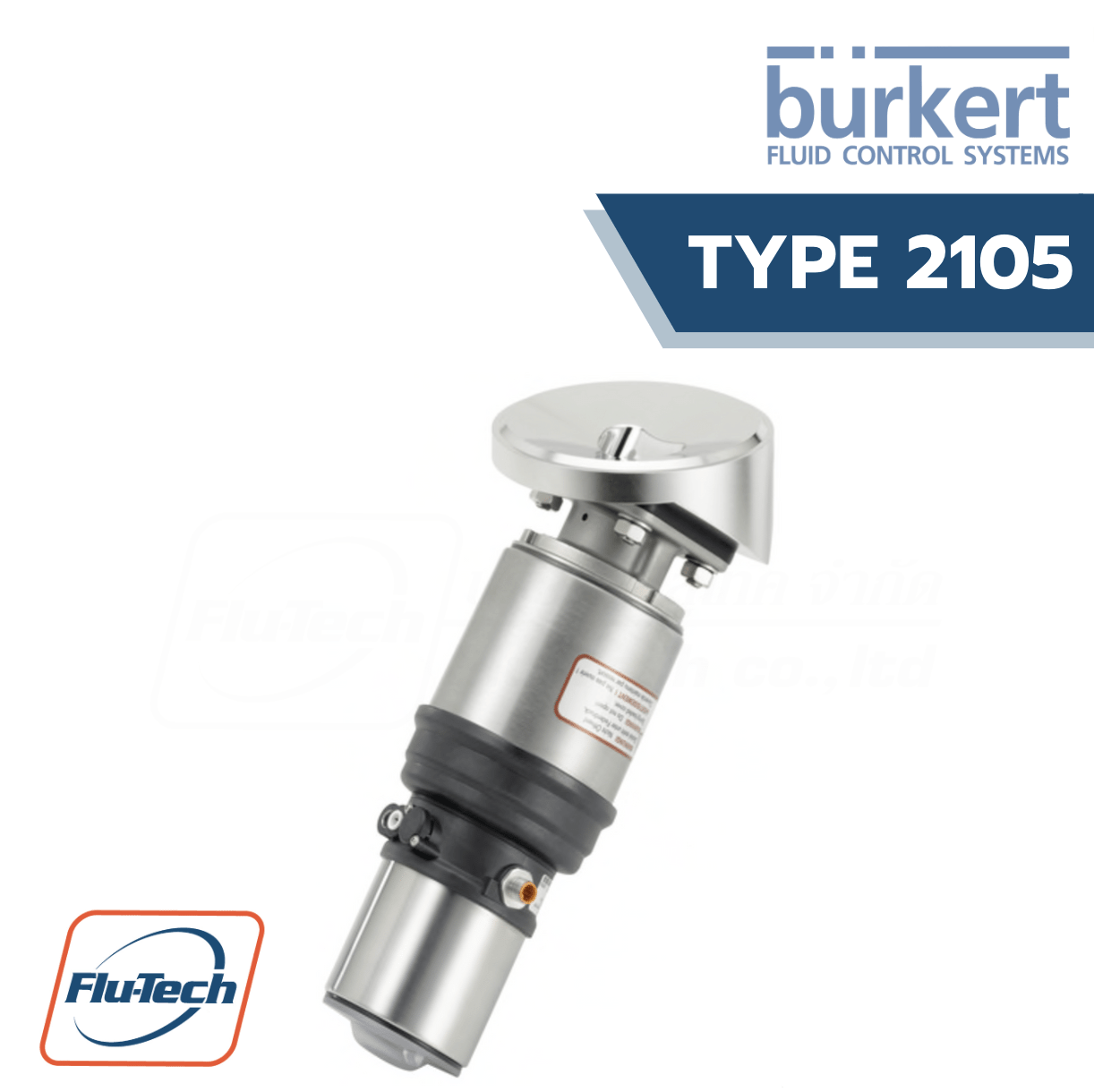

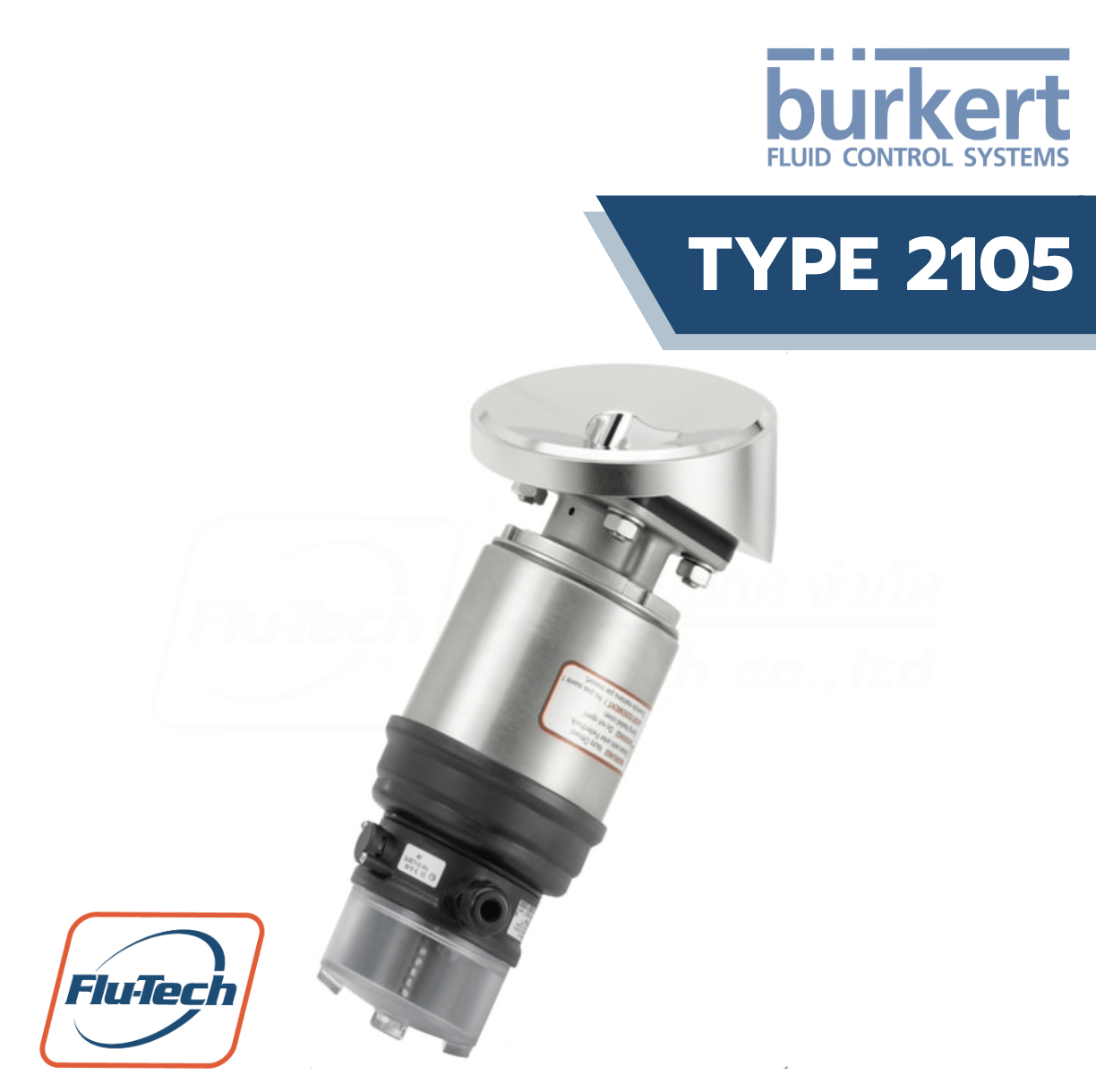

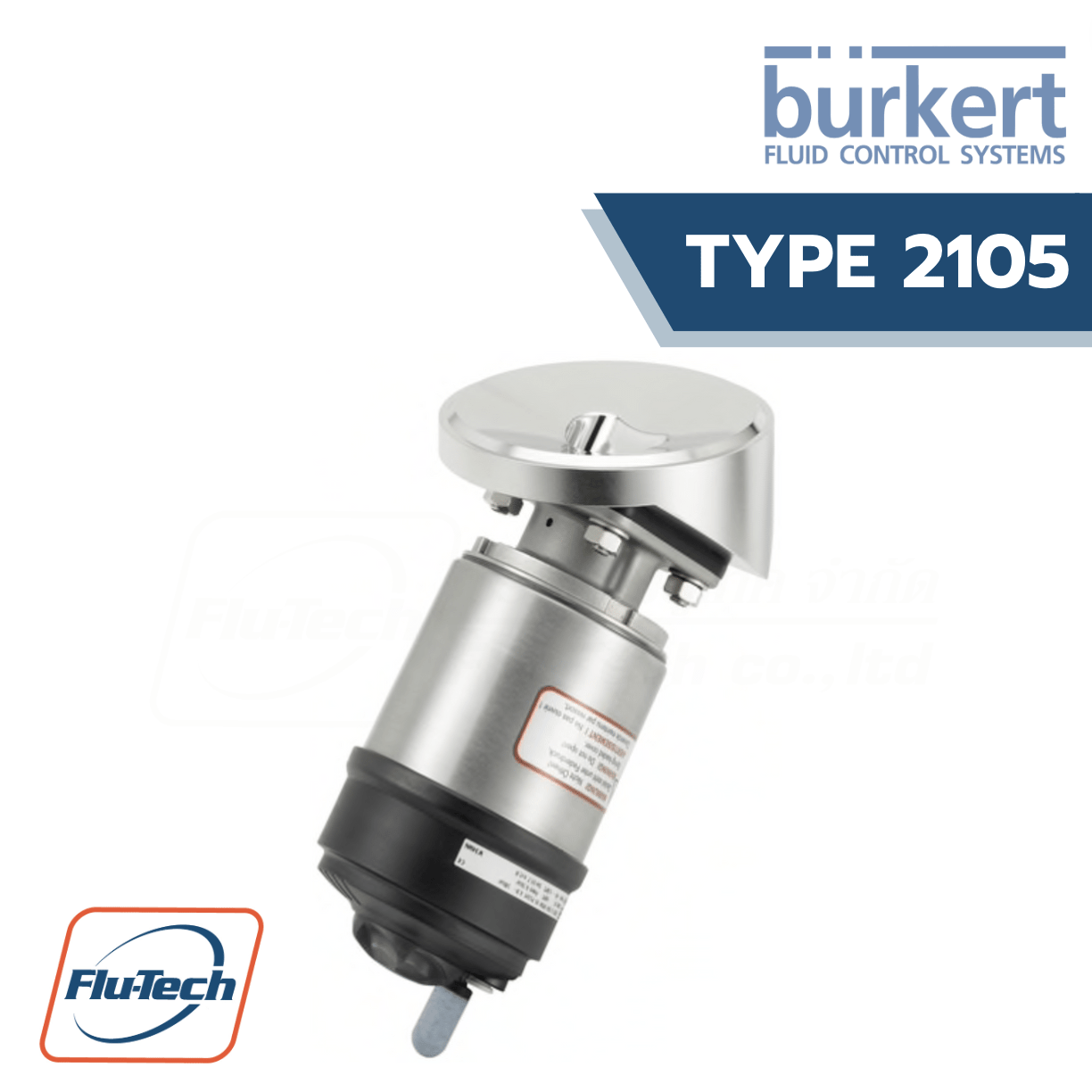

Tank bottom diaphragm valve with pneuma-tic actuator in stainless steel (Type ELEMENT) for decentralised automation

The externally controlled diaphragm valve Type 2105 consists of a pneumat-ically operated piston actuator, a diaphragm and a tank bottom valve body. The proven and robust actuator with stainless steel housing ensures use in hygienic or aggressive ambient conditions. The flow-efficient valve bodies with little dead space enable high flow rates and a wide range of possible uses. The valve body and the diaphragm are available in all common mate-rials and variants. The actuator has a compact, autoclavable design with a large stainless steel housing and gap-free seals. The integration of automation units Type ELEMENT is possible in all configuration levels (can be retrofit-ted); a fieldbus interface can also be integrated. An explosion-proof ATEX / IECEx device variant is available. It is a compact, smooth-surfaced and highly integrated system consisting of a valve and an automation unit with integrated pilot air ducts (no intake of ambient air). The add-on body is optionally avail-able in plastic or stainless steel (can be rotated 360°). The valve offers the degrees of protection IP65/67 and NEMA Type 4X and displays high chemical resistance.

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

BURKERT TYPE 2105 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

|

Dimensions

|

Detailed information can be found in chapter “4. Dimensions” on page 6.

|

|

Block body (VH) material

|

Stainless steel 1.4435/316 L

|

|

Block body (VI) material

|

Stainless steel 1.4435/BN2/ASME BPE; Fe <0.5%/C ≤0.03% |

|

Diaphragm material

|

EPDM (AD), PTFE/EPDM (EA), advanced PTFE/EPDM (EU), Gylon®/EPDM laminated (ER) |

|

Actuator material

|

PPS

|

| Actuator cover material | Stainless steel 1.4561 (316Ti) |

| Diaphragm size | 8…65 |

|

Standard surface quality: Block body (VH/VI)

|

Internal electrically polished : Ra ≤ 0.38 μm (NO17)1.) (ASME BPE SF4/DIN HE4) (external Ra ≤1.6 μm) / Internal mechanically polished : Ra ≤ 0.5 μm (NO14)1.) (ASME BPE SF1) (external Ra ≤1.6 μm)

|

Performance Data |

|

|

Pilot pressure (max.) (CF: A)

|

10 bar / 7 bar for actuator size 130

|

|

Pilot air ports

|

Push-in connector for external, Ø 6 mm or 1⁄4″ (Standard); thread G 1⁄8

|

Medium Data |

|

|

Medium

|

Neutral gases and fluids, highly purified, sterile, aggressive or abrasive medium

|

|

EPDM (AD) medium temperature

|

– 10…+ 143 °C (steam sterilisation + 150 °C for 60 min)

|

| PTFE/EPDM (EA) medium temperature |

– 10…+ 130 °C (steam sterilisation + 140 °C for 60 min)

|

| Advanced PTFE/EPDM (EU) medium temperature |

– 5…+ 143 °C (steam sterilisation + 150 °C for 60 min)

|

| GYLON®/EPDM laminated (ER) medium temperature |

– 5…+ 130 °C (steam sterilisation + 140 °C for 60 min)

|

|

Control medium

|

Neutral gases and fluids, highly purified, sterile, aggressive or abrasive medium |

Process/Port Connection & Communication |

|

|

Nominal diameter

|

DN06…DN65 (1⁄8″…21⁄2″)

|

Port Connections |

|

|

Welded connection for stainless steel body

|

DIN EN ISO 1127/ISO 4200/DIN 11866 series B / DIN 11850 series 2/DIN 11866 series A/DIN EN 10357 series A / ASME BPE/DIN 11866 series C

|

|

Clamp connection for stainless steel body

|

DIN 32676 series A (DIN pipe) / DIN 32676 series B (ISO pipe) / ASME BPE

|

Environment and Installation |

|

|

Installation position

|

Refer to the operating manual (Contact Flu-Tech for more information) |

| Ambient temperature | – 10…+60 °C autoclavable |

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th