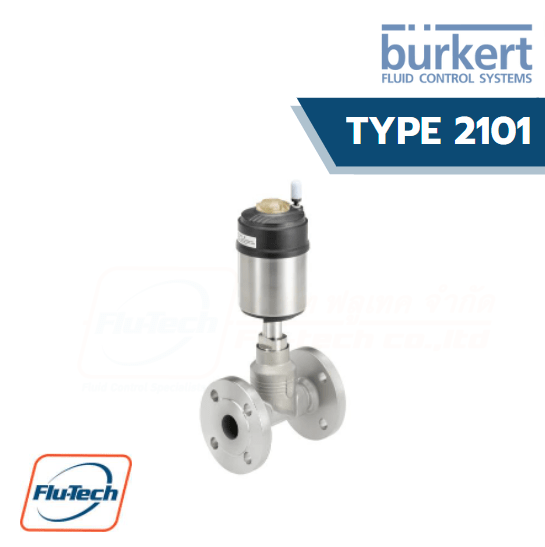

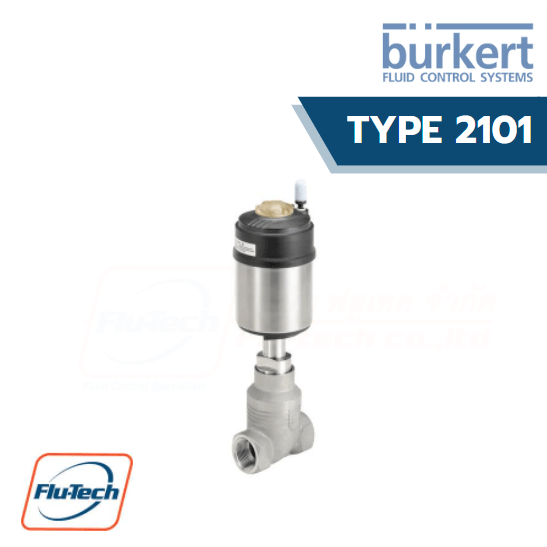

Pneumatically operated 2/2-way globe valve ELEMENT for decentralized automation

The Type 2101 globe valve is specially optimised for decentralised process automation and meets all practical requirements even under difficult operating conditions. Its unique design allows easy the integration of automation units in all expansion stages, from electrical/optical position feedback to pneumatic control and integrated fieldbus interface. Maximum service life and tightness are achieved by the proven self-adjusting v-seal packing gland. The highly integrated system of valve and automation unit is characterised by its compact and smooth design, integrated pilot air ducts, protection classes IP65/67, NEMA Type 4X and high resistance to chemicals.

Downloads

Data Sheet User ManualBURKERT TYPE 2101 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

| Dimensions | Detailed information can be found in chapter “5. Dimensions” on page 7. |

| Material | Detailed information can be found in chapter “4. Materials” on page 6. |

| Design | Globe valve |

| Nominal diameter | DN10…DN100, NPS ⅜…NPS 4 |

| Flow direction | Against closing direction (below seat), with closing direction (above seat) |

| Safety setting in case of power failure | Normally closed (control function A), normally open (control function B) |

Performance data |

|

| Operating pressure | 0 bar(g)…25 bar(g), vacuum version up to – 0.9 bar (g) (option), see “Operating limits for medium temperature and operating pressure” on page 16 |

| Nominal pressure | PN25 (DIN EN 1333), Class 150 (DIN EN 1759) |

| Pilot pressure | 2.5 bar(g)…10 bar(g), see “6.1. Fluidic data” on page 13 |

| KV value | 4.7 m³/h…140 m³/h, see “6.1. Fluidic data” on page 13 |

| Medium data | |

| Medium | Steam, water, neutral gases, alcohols, oils, fuels, hydraulic fluids, saline solutions, alkalis, organic solvents, fuel gases of category I, II and III acc. to Gas Appliances Regulation (EU) 2016/426 and oxygen |

| Medium temperature | – 40 °C…230 °C, see “6.2. Operating limits” on page 16 |

| Viscosity | Max. 600 mm²/s |

| Control medium | Air, neutral gases |

Process/Port connection & communication |

|

| Flange connection | DIN EN 1092 – 1 ANSI B16.5 JIS 10K |

| Threaded connection | G (DIN ISO 228 – 1) NPT (ASME B 1.20.1) Rc (ISO 7 – 1) |

| Welded connection | DIN EN ISO 1127 / ISO 4200 / DIN 11866 B DIN 11850 2 / DIN 11866 A ASME BPE / DIN 11866 C SMS 3008 |

Approvals and certificates |

|

| Conformity | Food contact 1935/2004(EG), FDA Drinking water Pressure Equipment Directive Gas Appliances Ordinance Machinery Directive |

| Explosion proof | Explosion proof ATEX / IECex |

| Material certificate | 2.2, 3.1 |

Environment and installation |

|

| Degree of protection | IP65/67 |

| Ambient temperature | – 10 °C…100 °C, see “6.2. Operating limits” on page 16 |

| Installation position | As required, preferably with actuator in upright position |

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th