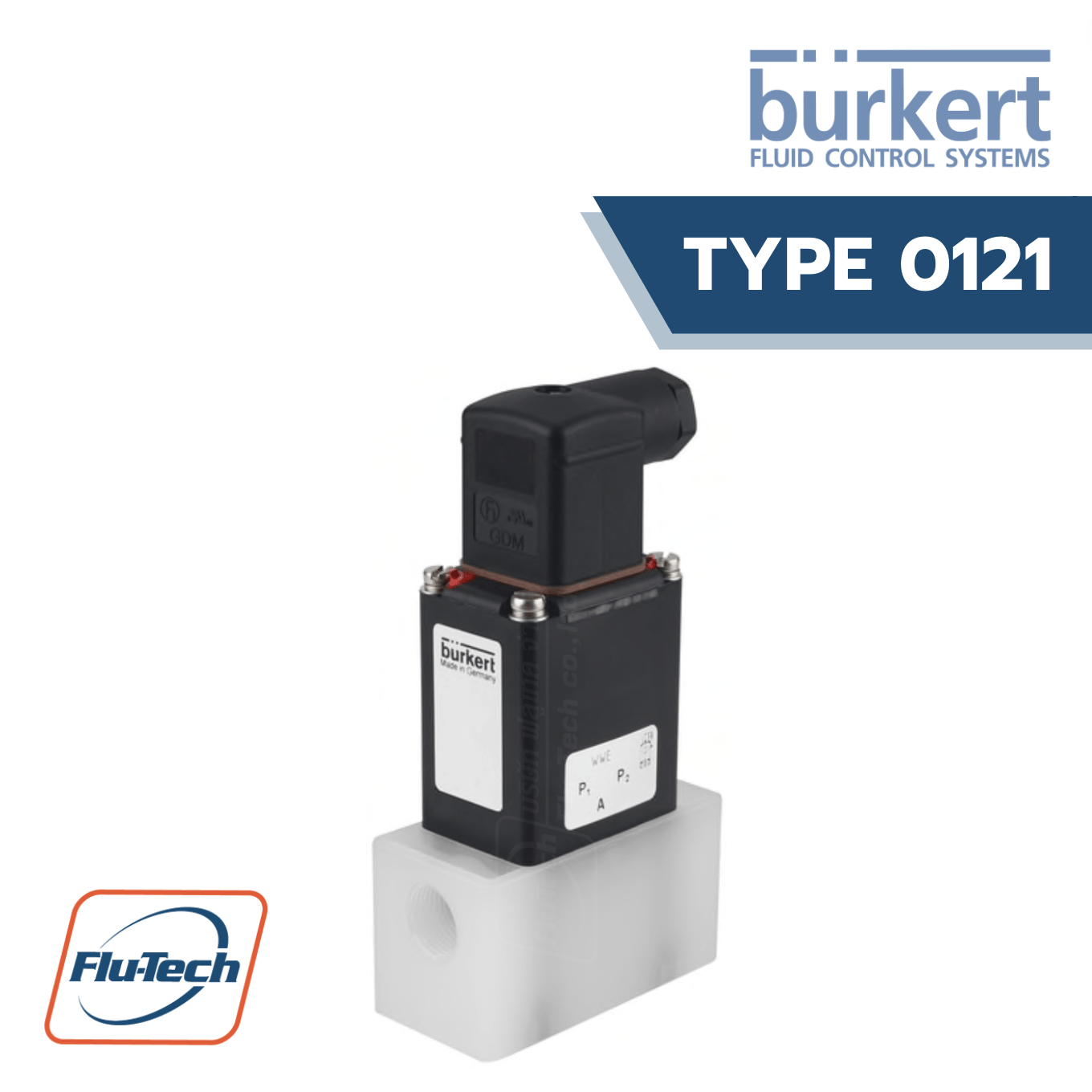

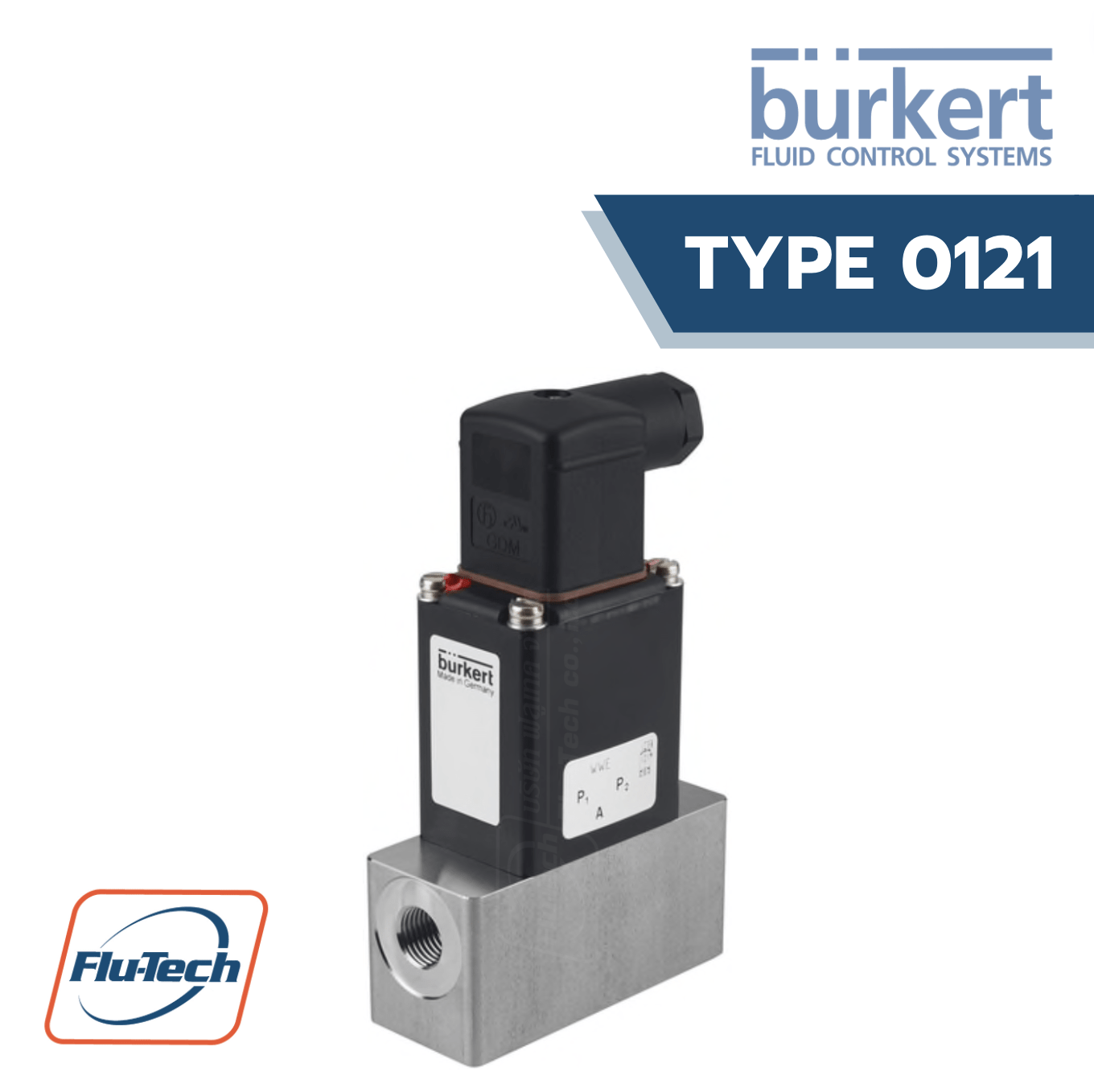

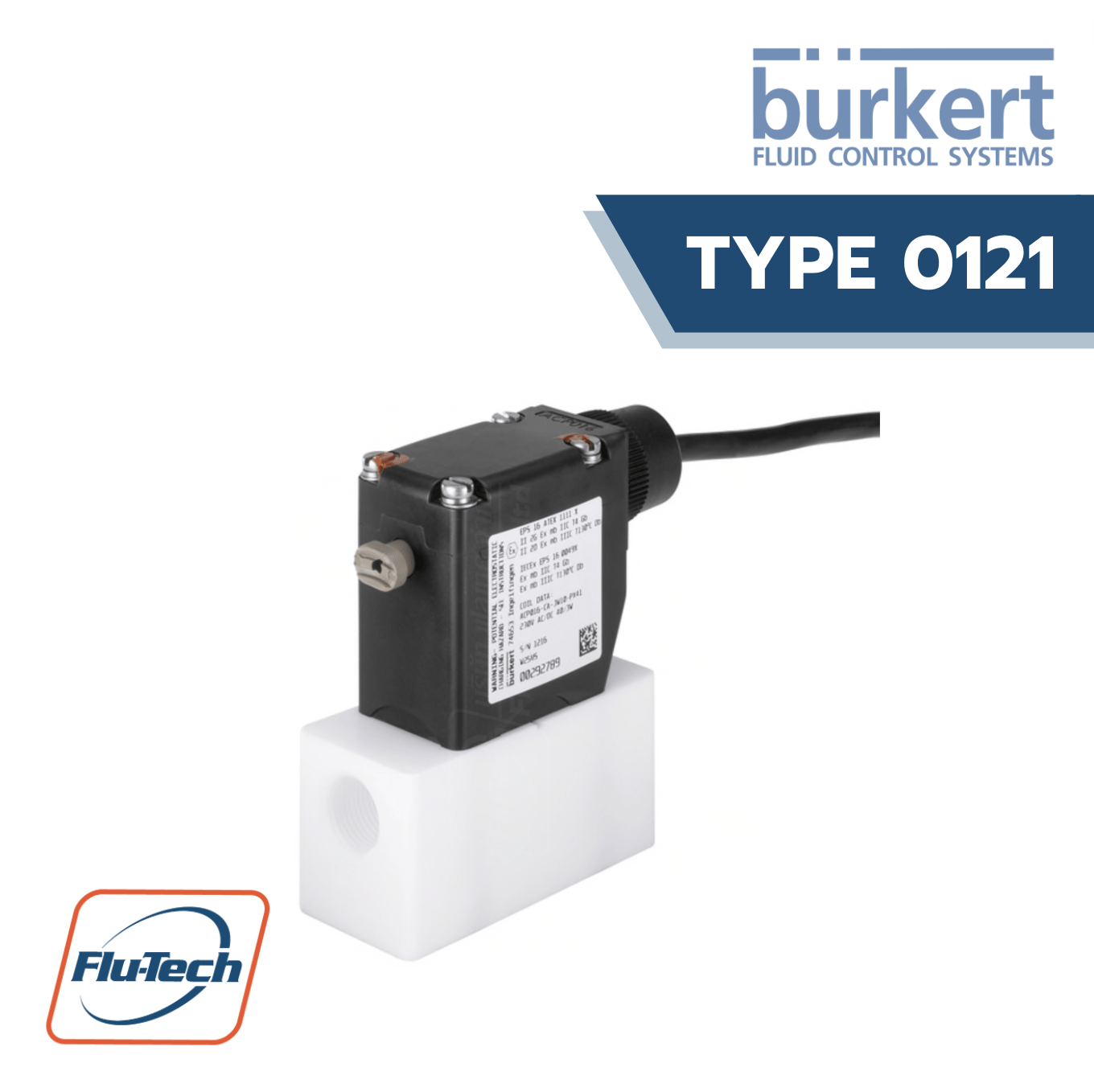

Direct-acting 2/2 or 3/2-way pivoted armature valve

The 0121 valve is a direct-acting, media separated pivoted armature valve. It is available as a 2/2 and 3/2-way variant. As a 3/2-way variant, it can be used as a distributor or mixing valve. Various diaphragm materials and circuit functions are available depending on the actual application. The range of bodies includes stainless steel (316L), PTFE and PVC versions. The solenoid coils are moulded with a chemically resistant epoxy. Since the coil system is separated from the medium by a diaphragm, the valve is especially suitable for critical media such as aggressive acids and lyes. The 0121 is equipped with manual override for start-up and testing. To reduce energy demands, all the coils can be delivered with electronic power reduction or as an impulse variant. The switching status can be indicated via position feedback as a binary or NAMUR signal. In combination with a plug to DIN EN 175301-803 Form A, the valves satisfy degree of protection IP65/67 – and NEMA 4X when combined with a stainless steel or plastic valve body

Downloads

Data Sheet User ManualBURKERT TYPE 0121 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

|

Dimensions

|

Detailed information can be found in chapter “4. Dimensions” on page 6. |

| Seal material |

FKM / FFKM / EPDM

|

| Body material |

PTFE / PVC (resistant acc. to DIN 8062, 8061) / PP (polypropylene) / PVDF / Stainless steel 1.4401

|

| Standard version weight |

With VA: 0.9 kg / With PVDF, PP and PVC: 0.38 kg / With PTFE: 0.5 kg

|

| Explosion-proofed version weight |

With VA: 1.15 kg / With PVDF, PP and PVC: 0.62 kg / With PTFE: 0.75 kg

|

| Orifice |

DN 2.0…DN 8.0 / FFKM only possible up to DN 6.0

|

| Thermal insulation class of solenoid coil | H |

Performance Data |

|

| Duty cycle with VA | 100% |

| Duty cycle with PVDF and PTFE |

40 % duty cycle (60 % intermittent operation) in 10 min at 8 W-version / 100 % duty cycle for 5 W-version or high-capacity electronic

|

| Duty cycle with PVC |

10% duty cycle (10 min) / 100 % duty cycle for version with high-capacity electronic

|

|

Standard version switching frequency

|

Max. 100/min with AC / Max. 10/min for UC (high-capacity electronic)

|

| Explosion-proofed version switching frequency | Medium temperature up to + 70 °C: max. 20/min / Medium temperature up to + 90 °C: max. 5/min |

|

Response times standard version – Frequency AC

|

Opening: 20 ms / Closing: 11 ms |

| Response times standard version – Frequency DC | Opening: 11 ms / Closing: 8 ms |

|

Response times explosion proofed version – Orifice 2…8

|

Opening: 30 ms / Closing: 40 ms

|

| Response times explosion proofed version – Circuit functions |

A, B, C, D, E, F, T (see “2. Circuit functions” on page 5)

|

Electrical Data |

|

|

Voltage tolerance

|

±10%

|

|

Power consumption standard – Frequency AC

|

Inrush: 30 VA / Hold: 15 VA / Hold: 8 W

|

| Power consumption standard – Frequency DC |

Cold: 11 W / Warm: 8 W

|

|

Power consumption explosion-proofed version – Frequency AC/DC

|

Inrush: 40 W / Hold: 3 W

|

|

Standard version voltages

|

24 V 50 Hz, 110 V 50 Hz, 230 V 50 Hz, 120 V 60 Hz, 240 V 60 Hz, 12 V DC, 24 V DC (Further voltages on request)

|

|

Explosion-proofed version voltages

|

24 V, 230 V (further voltages on request)

|

|

Safety fuse (explosion proofed version)

|

Appropriate inrush current (see “8.3. Ordering chart” on page 12)

|

Medium Data |

|

|

Viscosity

|

Max. 37 mm2/s |

|

Operating medium with FKM

|

Oxydizing acids and substances, hot oils with additives, salt solutions, waste gases |

| Operating medium with FFKM |

Aggressive fluids, hot air, hot oils, aromatics, ether, esther, ketones

|

| Operating medium with EPDM |

Alkalis, acids up to medium concentration, alkaline washing- and bleaching lyes

|

| Operating medium for all materials |

For more detailed information please consult the resistance chart, see “3.1. Chemical Resistance Chart – Bürkert resistApp” on page 5

|

|

Medium temperature standard version with PVDF or PP

|

EPDM: – 30 °C…+ 70 °C / FKM: – 10 °C…+ 70 °C / FFKM: – 10 °C…+ 70 °C

|

| Medium temperature standard version with PTFE or VA |

EPDM: – 30 °C…+ 90 °C / FKM: – 10 °C…+ 90 °C / FFKM: – 10 °C…+ 90 °C

|

| Medium temperature standard version with PVC |

EPDM: – 30 °C…+ 50 °C / FKM: – 10 °C…+ 50 °C / FFKM: – 10 °C…+ 50 °C

|

|

Medium temperature explosion proofed version with PVDF or PP

|

EPDM: – 20 °C…+ 70 °C / FKM: – 10 °C…+ 70 °C / FFKM: – 10 °C…+ 70 °C

|

| Medium temperature explosion proofed version with PTFE or VA |

EPDM: – 20 °C…+ 90 °C / FKM: – 10 °C…+ 90 °C / FFKM: – 10 °C…+ 90 °C

|

| Medium temperature explosion proofed version with PVC | EPDM: – 20 °C…+ 50 °C / FKM: – 10 °C…+ 50 °C / FFKM: – 10 °C…+ 50 °C |

Approvals and Certificates |

|

|

Standard version – Protection class

|

IP65 with cable plug

|

|

Explosion-proofed version – Protection class

|

IP65

|

| Explosion-proofed version – Type of protection |

II 2 G Ex mb IIC T4 Gb / II 2 D EX mb IIIC T130° Db

|

| Explosion-proofed version – Certificate |

EPS 16 ATEX 1 111 X / IECEx EPS 16.0049X

|

Product Connections |

|

|

Electrical connection – Standard version

|

Tag connector acc. to DIN EN 175301 – 803 Form A for cable plug type 2518/2509 (on request also with injected cable or terminal box)

|

| Electrical connection – Explosion-proofed version |

Impressed cable (HO5RN-F3G, 3 x 0.75 mm2) / Terminal box without safety fuse (Information about ACP016 see operating manual)

|

Environment and Installation |

|

|

Installation

|

As required, preferably with actuator upright

|

|

Ambient temperature (max.)

|

+ 50 °C

|

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th