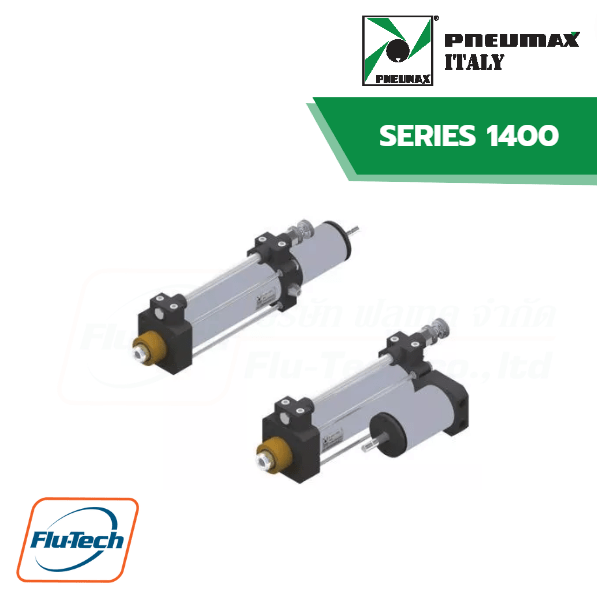

Hydraulic speed control check cylinders 1400 SERIES

The hydraulic speed control check normally couples with a pneumatic cylinder to provide uniform speed control. (Cylinder Ø63)

PNEUMAX – กระบอกไฮดรอลิคควบคุมความเร็ว Hydraulic speed control check cylinders 1400 SERIES

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

1400 SERIESGeneral

The SKIP and STOP valves are pneumatically actuated 2 ways poppet valves. The SKIP valve (accelerating device) is normally open and is equipped with a supplementary regulator for maximum speed control. It must be activated to obtain speed regulation. The STOP valve can be normally closed or normally open.

Construction characteristic

| Covers | Black anodized aluminum. |

| Barrels | Bright painted drawn steel. |

| Rod | C43 chromed steel |

| Tie rods | Plated zinc steel. |

| Piston | Aluminum |

| Waterproof seals | NBR rubber |

| Piston seal | FPM |

| Rod sea | PUR |

| Regulators group | Brass |

| Skip and stop valves | Black anodized aluminum |

| Circuit oil | Hydraulic with viscosity 2.9° Eat 50°C (viscosity index minimum 118) |

| Bore | 40 mm and 63 mm diameter. |

Technical characteristics

| Max connecting load : | 600 kg (Ø40) -1200 Kg (Ø63) |

| Min. and max. speed : | 60 – 10000 mm/min. |

| Working temperature : | -5°C – +70°C |

| Minimum pressure for the actuation of skip and stop valves : | 4 bar |

Attention: Dry air must be used for application below 0°C”

Standard strokes

50 – 100 – 150 – 200 – 250 – 300 – 350 – 400 – 450 – 500 mm minimum stroke for type 1400.stroke.03.05 and 1400.stroke.03.06, 150 mm.

Important: For heavier load we have available the hydraulic speed control check cylinders of 63 mm diameter suitable to withstand loads up to 1200 kg. For more information please contact our technical department.

Maintenance

The speed control check is a closed system and there are no external factors that can adversely affect its function. Care however, has to be exercised not to allow the hydraulic fluid level to drop below the minimum indicated on the auxiliary tank. Should this occur, cavitation, or worse, an air pocket would result causing erratic control. Additional fluid should be put in exclusively through a unidirectional valve by means of an appropriate syringe (such as our code number 1400.99.01). Excess fluid will be expelled through a vent into an appropriate container. It is necessary to completely disassemble the regulator and be sure to bleed the system to eliminate air pockets. We suggest that you create a vacuum before beginning to refill. This can be done with a small unidirectional valve turned up and repeatedly loaded with a syringe. The rod must be manually actuated successively releasing air through the valve using a small and pointed instrument.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th