What makes a Ball Valve and a Butterfly Valve Comparable?

In terms of operation mechanisms, both valves are arguably the simplest of the valve types available. They are extensively used in domestic, commercial, and industrial applications for flow control of fluids across a wide range of temperatures and pressures. They are quarter-turn rotary valves (90° turn from fully closed to fully open). Both valve types can be controlled manually, with an electric actuator or with a pneumatic actuator. Butterfly and ball valves are relatively cheap, easy to maintain, reliable, and have a long life expectancy than other valve types.

Both butterfly valves and ball valves offer unique benefits, so choosing between them in certain processes is a hard choice. It can be problematic when a process requires valve characteristics that both valves have. We need a deeper understanding of the butterfly valve vs ball valve in order to pick the correct valve. Therefore, it is essential to know what type of valve will suit your specific application.

What is a Butterfly Valve?

BURKERT Type 2674 – Plastic Butterfly ValveA butterfly valve is a quarter-turn rotational motion valve used to control media flow. The “butterfly” is a the disc connected to a rod and the valve closes when the rod rotates the by a quarter turn to a position perpendicular to the flow. The valve will open when the disc rotates back allowing the media to flow. Butterfly valves are used in a wide variety of process line and industries especially in water supply, collection, and distribution, as well as in pumping stations. They also have a broad range of uses especially in flow isolation. They are used for on-off or modulating services are are popular due to their lightweight, small installation footprint, low costs, quick operation, and availability of larger sizes. Butterfly valves can be operated with handles, gears, or automatic actuators. For more information regarding the butterfly valve, click here.

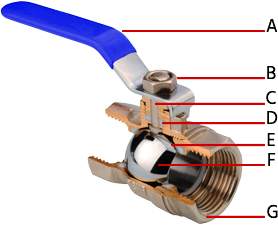

What is a Ball Valve?

BURKERT Type 2657 – PVC-U Ball ValveA ball valve is a shut off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. By rotating the ball by a quarter turn (90°) around its axis, the medium can flow through or is blocked. They are characterized by a long service life and provide a reliable sealing throughout their lifespan even when the valve is not used for a long time. As a result, a ball valve is one of the more popular choice of shut off valve. A ball valve is more resistant against contaminated media than most other types of valves. In special versions, ball valves are also used as a control valve. This application is less common due to the relatively limited accuracy of controlling the flow rate in comparison with other types of control valves. For more information regarding the butterfly valve, click here.

Advantages and Disadvantages

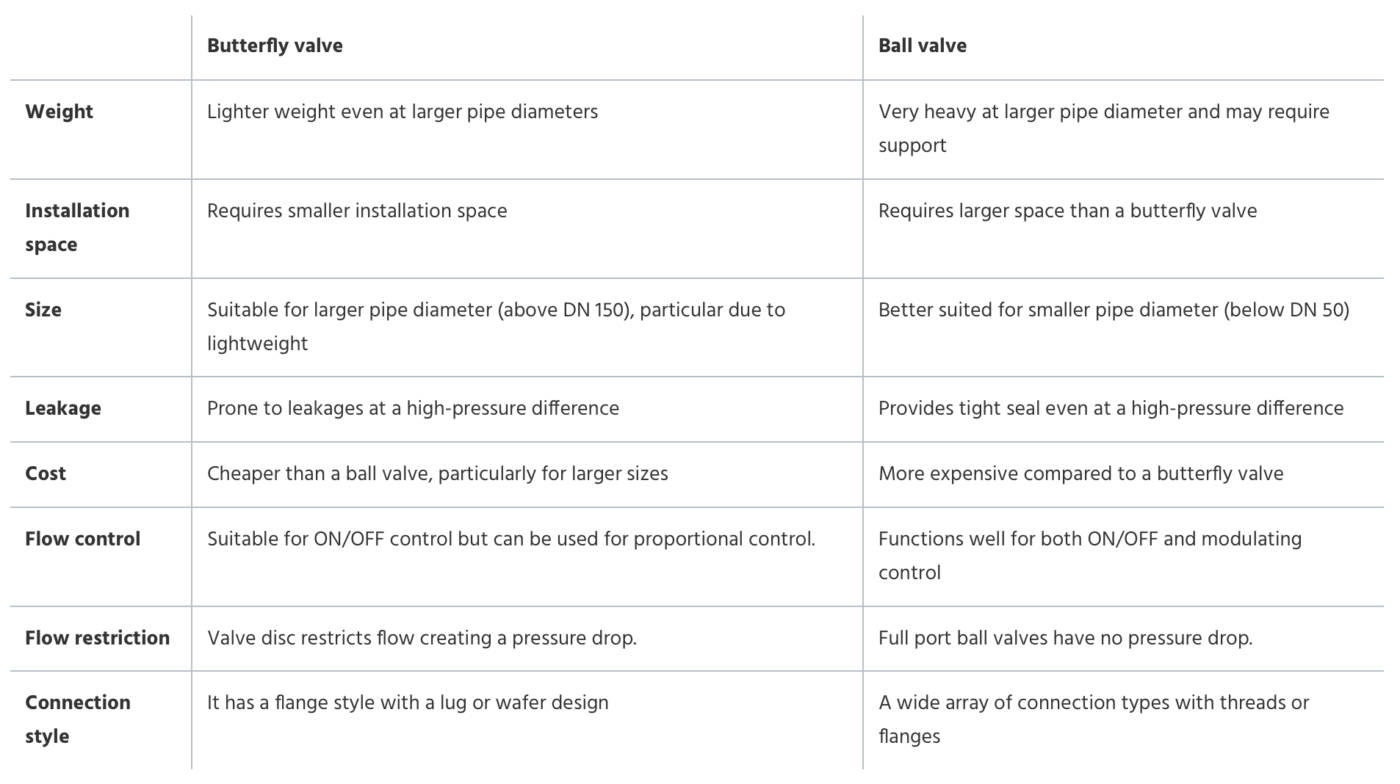

Selection Criteria

- Application: Butterfly valves are commonly used in water-based processes such as sewages, beer and soda production, etc. They are popular in chemical, agricultural, waste treatment plants, and food industries, partly because they are easy to clean. Ball valves can handle both liquid and gases with some solid particles (slurry). They are common in process plants, power plants, petroleum refining, oil, and gas exploration as they can be pigged for cleaning.

- Ports: A butterfly valve can only have two ports, while a ball valve can have more than two ports.

- Flow capacity: Butterfly valves can provide a larger flow capacity as they are readily available at a larger pipe diameter than a ball valve.

- Flow regulation: Both valve types can be used for on/off control and proportional control, but ball valves are typically used for proportional due to better flow regulation.

- Sealing: Ball valves provide a tight seal in process applications that require zero leakages when shutoff.

- Operating condition: Ball valves can operate up to 1,000 bar and 400°C. Butterfly valves typically operate at a lower pressure (less than 50 bar) and temperature (less than 250°C).

Reference: Tameson, Aignep, Burkert