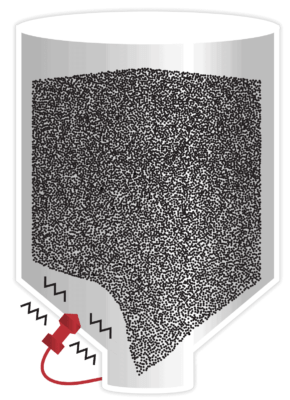

Air knockers are like pneumatic hammers.

Compressed air pushes the piston against the vessel wall and makes it vibrate. The shaking and agitation loosen material that cling to the vessel walls.

Air knockers (or air hammers) are used to:

- Shake off excess powder

- Remove products from molds

- Remove water and splatter

- Prevent adhesion of workpieces

AIR KNOCKERS VS AIRSWEEP®

ARE YOU JUST GETTING A MORE EXPENSIVE HAMMER?

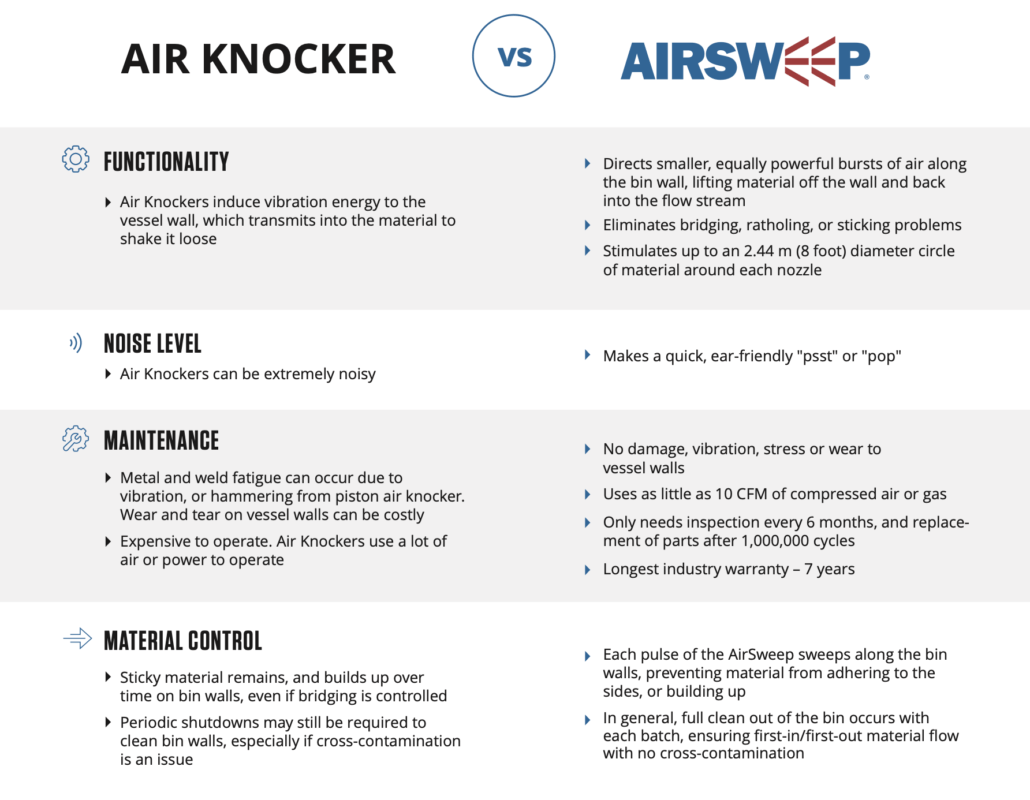

AIR KNOCKERS ARE NOT EFFICIENT FLOW AIDS

POOR MATERIAL CONTROL

- Not effictive for all materials

- Sticky residue can remain on walls

- Does not promote first in/first out flow

EXPENSIVE

- Metal fatigue damages the vessels

- Uses a lot of plant air and electricity

INCONVENIENT

- Causes worker stress and can affect hearing

- Vessels still require periodic manual cleaning

Reference: AirSweep®