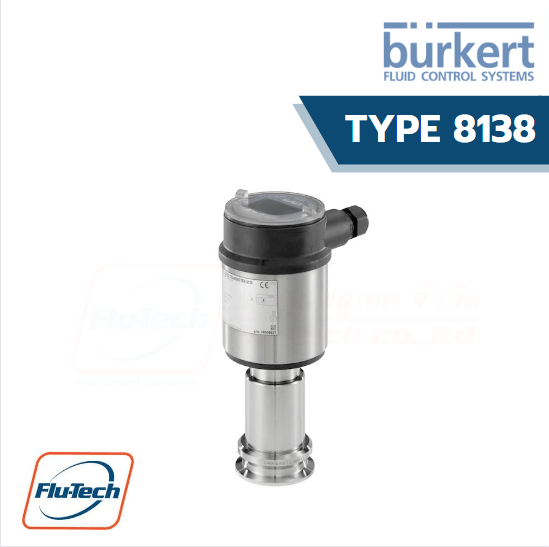

Radar level meter for hygienic applications

Type 8138 is a non-contact radar level meter for continuous level measurement.

It is particularly suitable for use in small vessels that contain beverage liquids under hygienic process conditions.

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

BURKERT TYPE 8138 สามารถใช้ได้ร่วมกับ

General Technical Data

Product properties |

|

| Materials | Please make sure the device materials are compatible with the fluid you are using. Detailed information can be found in chapter “3.1. Chemical Resistance Chart – Bürkert resistApp” on page 5. |

| Non wetted parts | |

| Housing | PBT, stainless steel 316L (1.4404) |

| Cover | PC transparent |

| Seal between housing and housing cover | EPDM |

| Cable gland | PA |

| Blind plug | PA |

| Ground terminal | Stainless steel 316Ti/316L (1.4571/1.4435) |

| Wetted parts | |

| Process connection | Stainless steel 316L |

| Process seal | EPDM |

| Antenna | TFM-PTFE |

| Dimensions | Detailed information can be found in chapter “4. Dimensions” on page 6. |

| Weights | 3.5…15.5 kg (depending on process connection and antenna) |

| Measuring variable | Distance between the end of the level meter antenna and the product surface. Detailed information can be found in chapters “5.1. Measurement deviation diagram” on page 9 and “6.1. Measuring principle” on page 9. |

| Measuring range | Max. 35 m Recommended measuring range: • 0.05…15 m (clamp 2″, DN 25 connection or flange DN 50 version) • 0.05…35 m (flange DN 100) |

| Beam angle1.) | • 18° (clamp 2″, DN 25 connection or flange DN 50 version) • 10° (flange DN 100) |

| Damping (63 % of the input value) | 0…999 s, adjustable |

| Step response time2.) | ≤ 3 s |

| Product accessories Display | LCD in full dot matrix (optional, must be ordered separately). Detailed information can be found in chapter “7.4. Ordering chart accessories” on page 12. |

Performance data |

|

| Measurement deviation | ± 2 mm (measuring distance > 0.5 m) Detailed information can be found in chapter “5.1. Measurement deviation diagram” on page 9. |

| Measuring range resolution | 1 mm |

| Measuring frequency | K-Band (26 GHz technology) |

| Measuring cycle time2.) | Approx. 450 ms |

| Temperature drift | • Digital output: ± 3 mm/10 K, max. 10 mm • Current output: < 0.03 %/10K relating to the 16 mA span or ≤ 0.3 % |

| Repeatability4.) | ≤ 1 mm |

| Vibration resistance | 4 g with 5…200 Hz according to EN 60068-2-6 (vibration at resonance) |

| Shock resistance | 100 g, 6 ms according to EN 60068-2-27 (mechanical shock) |

Electrical data |

|

| Operating voltage (Un) | • Without display/configuration module: – 9.6…35 V DC – 9.6…30 V DC (Ex ia instrument) • With display/configuration module: – 16…35 V DC – 16…30 V DC (Ex ia instrument) |

| Power Source (not supplied) | Limited power source according to UL/EN 60950-1 standards or limited energy circuit according to UL/EN 61010-1 §9.4 |

| Starting current | ≤ 3.6 mA; ≤ 10 mA for 5 ms after switching on |

| DC reverse polarity protection | Yes |

| Output signal | 4…20 mA/HART |

| Signal resolution | 0.3 µA |

| Range of the output signal | 3.8…20.5 mA/HART (default setting) |

| Load resistor | (Un – Umin.)/0.022 A |

| Fault signal | Current output: mA value unchanged, 20.5 mA, 22 mA or < 3.6 mA (adjustable) |

| Max. output current | 22 mA |

| Residual ripple (at DC) | • For 9.6 V < Un < 18 V: ≤ 0.7 Veff (16…400 Hz) • For 18 V < Un < 35 V: ≤ 1.0 Veff (16…400 Hz) |

| Voltage supply cable | • Cable diameter: 5…9 mm • Wire cross-section (spring-loaded terminals): – massive wire, stranded wire: 0.2…2.5 mm2 (AWG 24…14) – stranded wire with end sleeve: 0.2…1.5 mm2 (AWG 24…16) |

Media data |

|

| Process temperature | • With Clamp, flange connection: – 40 °C…+ 200 °C (- 40 °F…392 °F) • With DN 25 connection:- 40 °C…+ 130 °C (- 40 °F…266 °F) |

| Process pressure | • With Clamp connection: – 1…16 bar (- 14.51…232.16 PSI/- 100…1600 kPa) • With DN 25 connection: – 1…10 bar (- 14.51…145.1 PSI/- 100…1000 kPa) • With flange connection: according to flange rules |

Process/Port connection & communication |

|

| Process connection | • Clamp 2″ • DN 25 connection adapted for GEA Tuchenhagen VARINLINE process connections • Flange DN 50, DN 100 DIN 2501 |

| Electrical connection | Cable glands M20 x 1.5 |

Approvals and Certificates |

|

| Standards Degree of protection according to IEC/EN 60529 |

IP66/IP67 with M20 x 1.5 gland mounted and tightened |

| Overvoltage category according to IEC 61010-1 | Category III |

| Protection class according to IEC 61010-1 |

Class III |

| Directives | |

| CE directives | The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination Certificate and/or the EU Declaration of conformity (if applicable) |

| NAMUR recommendations | NE21- Electromagnetic compatibility of equipment NE43 – Signal level for fault information from measuring transducers NE53 – Compatibility of field devices and display/adjustment components NE107 – Self-monitoring and diagnosis of field devices |

| Approvals | |

| ATEX | EN 60079-0, EN 60079-11, EN 60079-26 Detailed information can be found in chapter “2.1. ATEX-Certification” on page 5. |

Environment and installation |

|

| Ambient temperature | Operation and storage: – 40 °C…+ 80 °C (- 40 °F…+ 176 °F) |

| Relative air humidity | 20…85 %, without condensation |

| Height above sea level | By default: max. 2000 m With connected overvoltage protection: max. 5000 m |

| Pollution degree | Degree 4 (when used with fulfilled housing protection) |

*For selecting thecorrect product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th