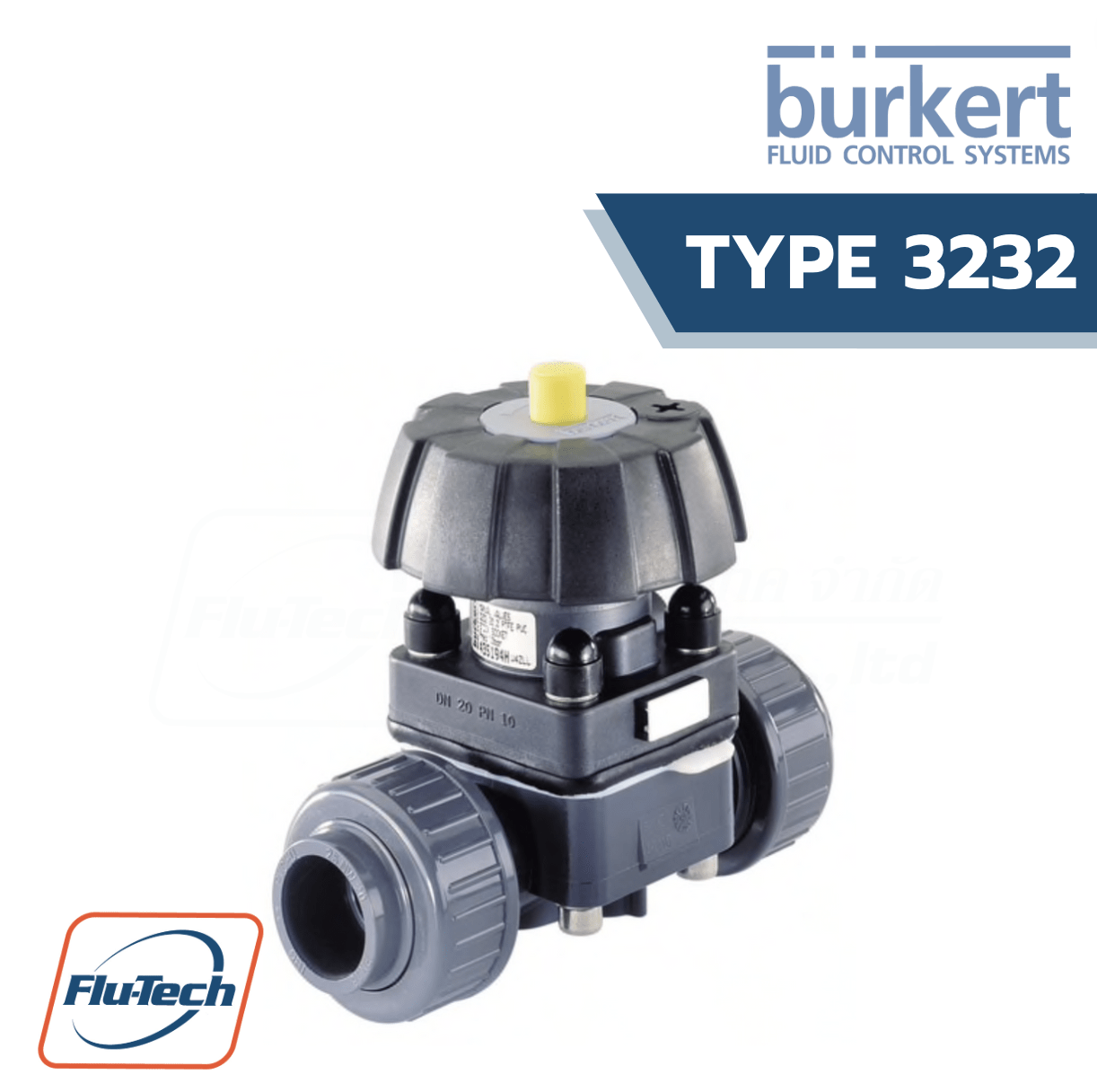

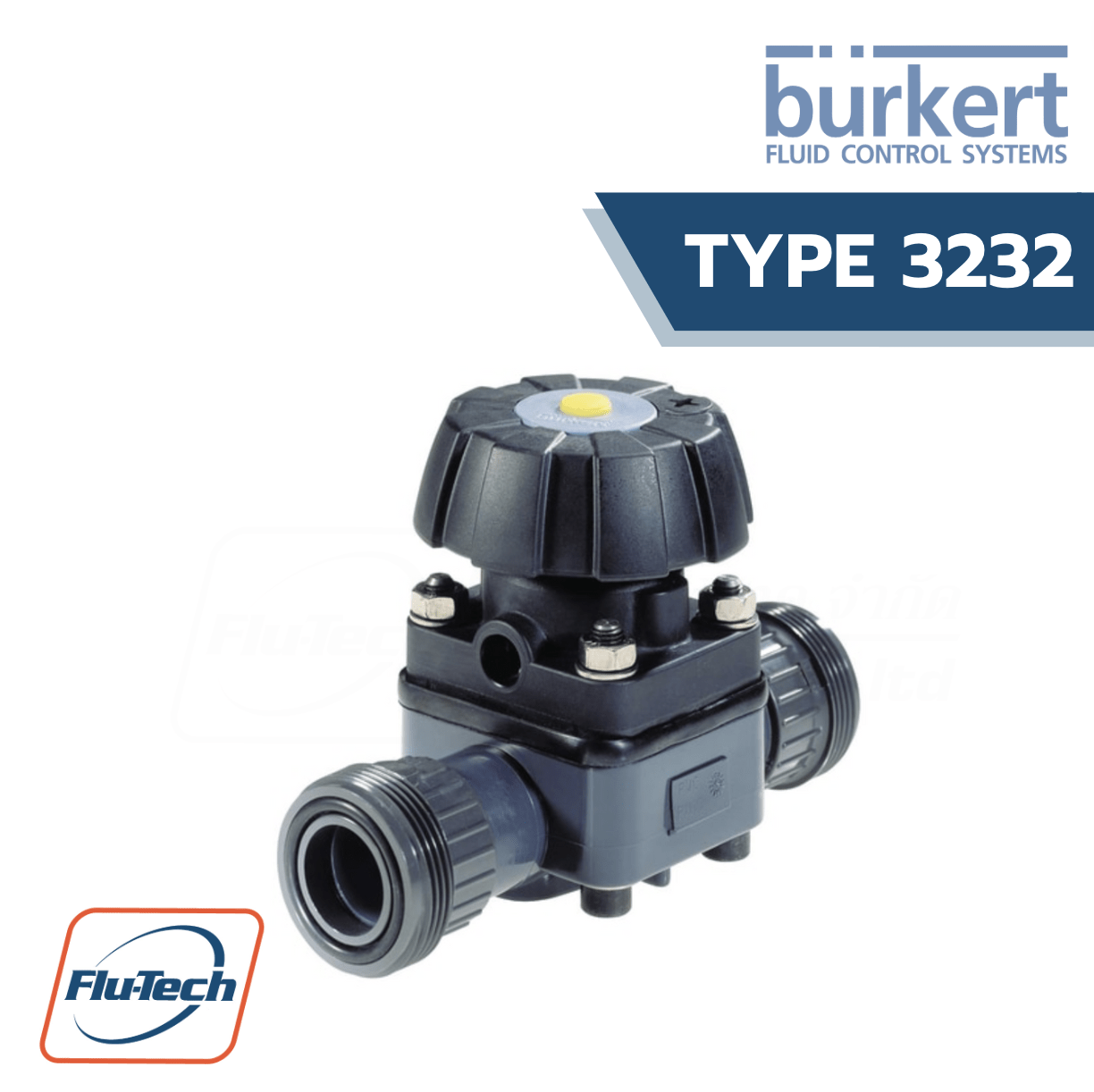

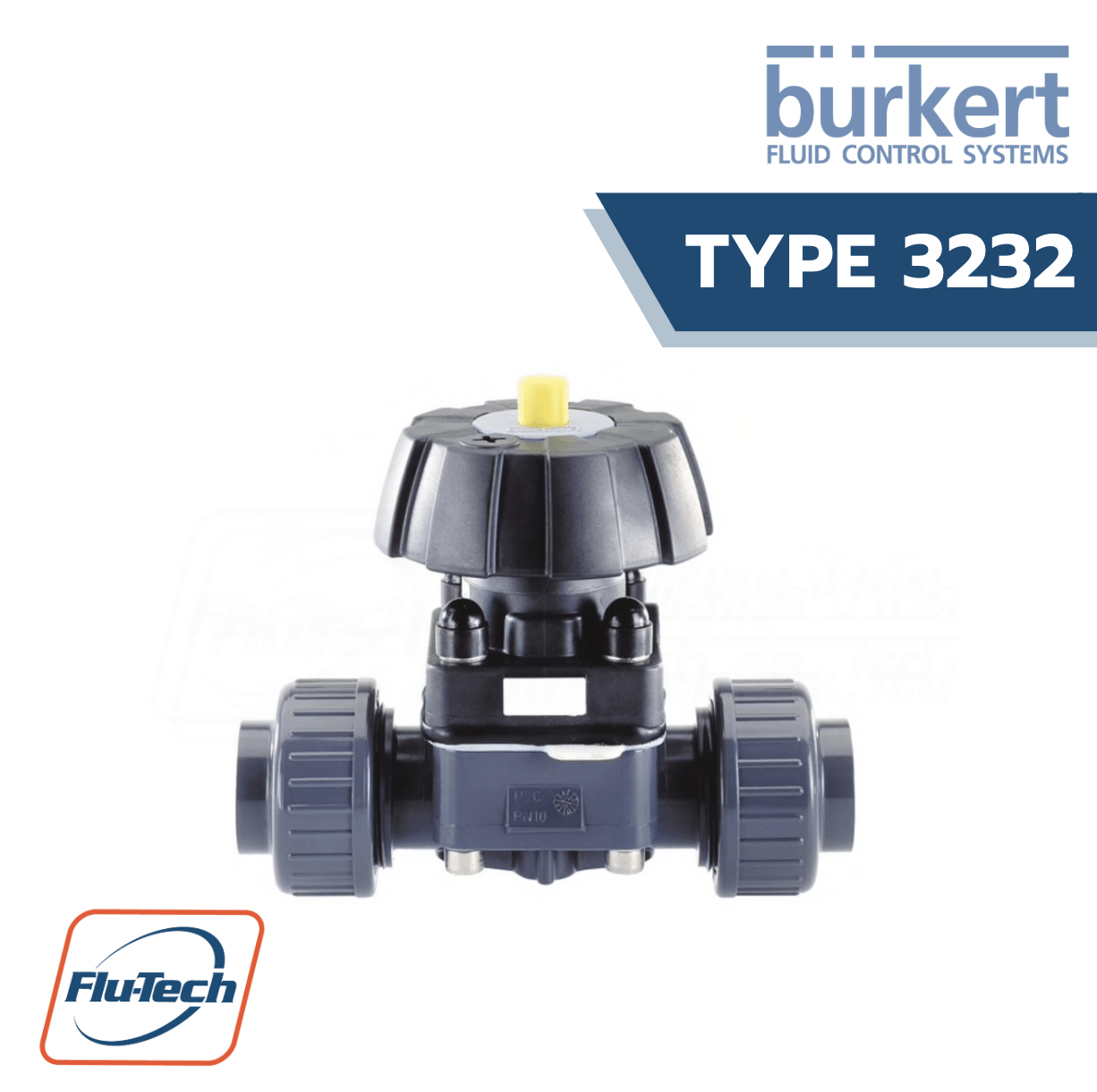

2/2-way diaphragm valve with manually operated actuator

The hand-operated diaphragm valve Type 3232 consists of a hand-operated actuator, a diaphragm and a 2-way body. The manual actuator with plastic handwheel ensures use in hygienic or aggressive ambient conditions. The flow-optimised valve body with minimum dead space enables high flow rates and a wide range of possible applications. The valve bodies are available in PP, PVC-U, PVDF. The membranes are available in the usual materials and designs. The actuator has a compact design and is compatible with all other Bürkert diaphragm valves.

DOWNLOAD CATALOG (ดาวน์โหลดแคตตาล็อก)

BURKERT TYPE 3232 สามารถใช้ได้ร่วมกับ

General Technical Data

Product Properties |

|

|

Dimensions

|

Detailed information can be found in chapter “4. Dimensions” on page 7.

|

|

Forged body (VS) material

|

Forged stainless steel 316L/1.4435/BN2, Fe <0.5%/C ≤0.03%

|

| Tube valve body (VP) material | Stainless steel 316L/1.4435/BN2 |

| Cast body (VG) material | Cast stainless steel 316L/1.4435 |

| Plastic body (PV; PD; PP) material |

PVC (PVC-U); PVDF; PP

|

| Diaphragm material | EPDM (AD), PTFE/EPDM (EA), advanced PTFE/EPDM (EU), Gylon®/EPDM laminated (ER) |

| Actuator (actuator/handwheel) – Diaphragm size 8…50 material |

PPS (Stainless steel on request)/PPS (Stainless steel on request)

|

| Actuator (actuator/handwheel) – Diaphragm size 65…100 material |

Stainless steel/Stainless steel

|

|

Diaphragm size

|

8…100; for tube valve body 8…50; for plastic body 15…100

|

|

Forged body (VS) standard surface quality

|

Internal electrically polished : Ra ≤ 0.38 μm (NO17) (ASME BPE SF4/DIN HE4) (external forged surface electrically polished) / Internal mechanically polished : Ra ≤ 0.5 μm (NO14)1.) (ASME BPE SF1) (external forged surface)

|

|

Tube valve body (VP) standard surface quality

|

Internal electrically polished : Ra ≤ 0.38 μm (NO17) (ASME BPE SF4/DIN HE4) / External glass bead blasted: Ra ≤ 1.6 μm (NO01) / Internal glass bead blasted: Ra ≤ 1.6 μm (NO05)

|

|

Cast body (VG) standard surface quality

|

Internal electrically polished : Ra ≤ 0.6 μm (NO16) (ASME BPE SF6) (external cast surface electrically polished) / Internal mechanically polished : Ra ≤ 0.76 μm (NO06) (ASME BPE SF3/DIN H2) (external cast surface)

|

Medium Data |

|

|

Operating medium

|

Neutral gases and fluids, highly purified, sterile, aggressive or abrasive medium

|

|

EPDM (AD) medium temperature

|

10…+ 143 °C (steam sterilisation + 150 °C for 60 min)

|

| PTFE/EPDM (EA) medium temperature | – 10…+ 130 °C (steam sterilisation + 140 °C for 60 min) |

| Advanced PTFE/EPDM (EU) medium temperature | – 5…+ 143 °C (steam sterilisation + 150 °C for 60 min) |

| GYLON®/EPDM laminated (ER) medium temperature | – 5…+ 130 °C (steam sterilisation + 140 °C for 60 min) |

| Plastic body medium temperature | See “3.2. Pressure temperature diagram for plastic body” on page 5 |

Process/Port Connection & Communication |

|

|

Nominal diameter

|

DN06…DN100 (1⁄8″ …4″)

|

|

Port connections for stainless welded connection

|

DIN EN ISO 1127/ISO 4200/DIN 11866 series B / DIN 11850 series 2/DIN 11866 series A/DIN EN 10357 series A / ASME BPE/DIN 11866 series C

|

| Port connections for stainless clamp connection |

DIN 32676 series A (DIN pipe) / DIN 32676 series B (ISO pipe) / ASME BPE

|

| Spignot Port connections for plastic body |

DN15…DN50

|

| True Union Port connections for plastic body | DN15…DN50 |

| Loose Flange Port connections for plastic body | DN15…DN65 |

Environment and Installation |

|

| Installation position |

See operating manual

|

|

PPS/PPS ambient temperature: actuator (actuator/handwheel

|

0…+ 130 °C (short-term up to + 150 °C)

|

| Stainless steel/PPS ambient temperature: actuator (actuator/handwheel | 0…+ 130 °C (short-term up to + 150 °C) |

| Stainless steel/Stainless steel ambient temperature: actuator (actuator/handwheel |

10…+ 140 °C (short-term up to + 150 °C)

|

*For selecting the correct product please refer to the technical data, images and notes for proper use according to the data sheet, or contact Flu-Tech directly.

สอบถามข้อมูลเพิ่มเติม ติดต่อเรา :

02-384-6060 (อัตโนมัติ) [email protected] บริษัท ฟลูเทค จำกัด Flu-tech @flutech.co.th